Condition monitoring involves real-time data collection and analysis of equipment parameters such as vibration, temperature, and pressure to detect anomalies and signs of wear. Predictive maintenance leverages this data with advanced algorithms and machine learning to forecast failures and schedule maintenance activities proactively, reducing unexpected downtime. Implementing predictive maintenance enhances asset reliability and extends machinery lifespan by addressing potential issues before they escalate.

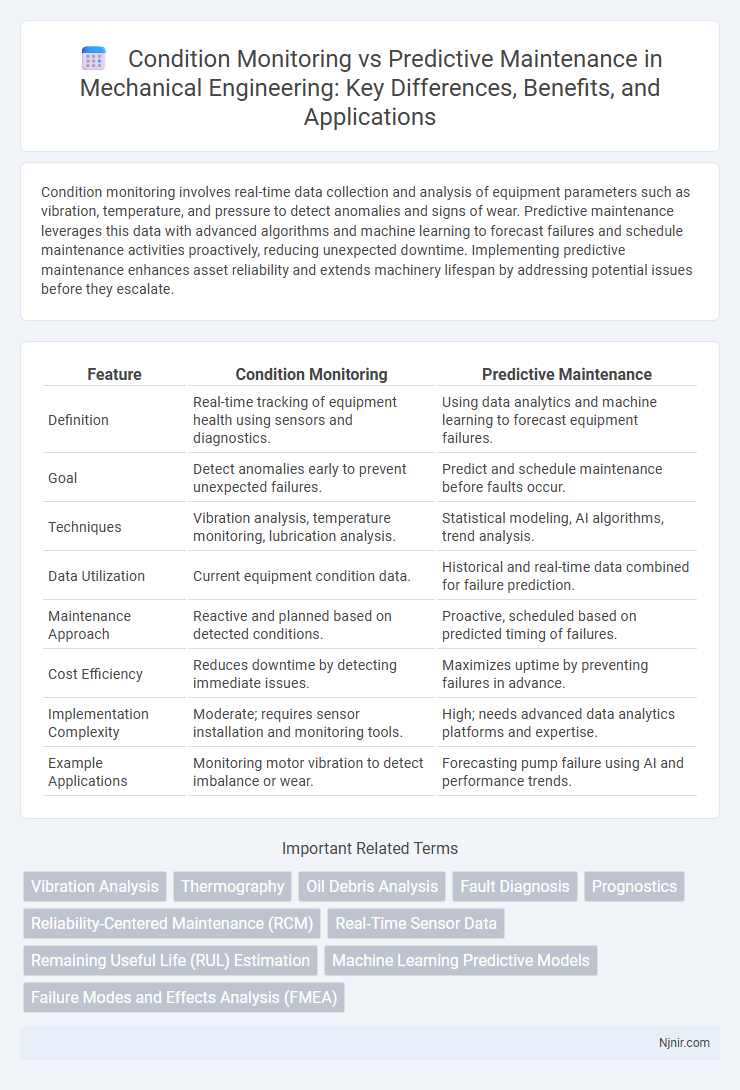

Table of Comparison

| Feature | Condition Monitoring | Predictive Maintenance |

|---|---|---|

| Definition | Real-time tracking of equipment health using sensors and diagnostics. | Using data analytics and machine learning to forecast equipment failures. |

| Goal | Detect anomalies early to prevent unexpected failures. | Predict and schedule maintenance before faults occur. |

| Techniques | Vibration analysis, temperature monitoring, lubrication analysis. | Statistical modeling, AI algorithms, trend analysis. |

| Data Utilization | Current equipment condition data. | Historical and real-time data combined for failure prediction. |

| Maintenance Approach | Reactive and planned based on detected conditions. | Proactive, scheduled based on predicted timing of failures. |

| Cost Efficiency | Reduces downtime by detecting immediate issues. | Maximizes uptime by preventing failures in advance. |

| Implementation Complexity | Moderate; requires sensor installation and monitoring tools. | High; needs advanced data analytics platforms and expertise. |

| Example Applications | Monitoring motor vibration to detect imbalance or wear. | Forecasting pump failure using AI and performance trends. |

Introduction to Condition Monitoring and Predictive Maintenance

Condition monitoring involves continuous or periodic measurement of equipment parameters such as vibration, temperature, and pressure to detect early signs of potential failure. Predictive maintenance uses condition monitoring data combined with advanced analytics and machine learning algorithms to forecast equipment failures before they occur, optimizing maintenance schedules. Both strategies aim to reduce downtime and maintenance costs by shifting from reactive to proactive asset management.

Defining Condition Monitoring in Mechanical Engineering

Condition monitoring in mechanical engineering involves continuous or periodic measurement of equipment parameters such as vibration, temperature, and oil analysis to detect early signs of wear or failure. This data-driven approach enables timely maintenance decisions, reducing unexpected breakdowns and extending machinery lifespan. Unlike predictive maintenance, which uses advanced analytics and machine learning for failure prediction, condition monitoring primarily focuses on real-time health assessment through sensor data interpretation.

What is Predictive Maintenance?

Predictive maintenance uses real-time data and advanced analytics to forecast equipment failures before they occur, minimizing downtime and optimizing maintenance schedules. It relies on condition monitoring techniques such as vibration analysis, temperature measurement, and oil analysis to detect anomalies and signs of wear. By predicting when maintenance is needed, predictive maintenance reduces costs and extends the lifespan of machinery compared to traditional preventive approaches.

Key Differences Between Condition Monitoring and Predictive Maintenance

Condition monitoring continuously tracks equipment parameters such as vibration, temperature, and pressure to detect abnormalities in real time, while predictive maintenance uses historical data and advanced analytics to forecast potential failures before they occur. Condition monitoring provides immediate status updates, enabling quick responses to emerging issues, whereas predictive maintenance schedules interventions based on predicted failure timelines to optimize maintenance efforts and reduce downtime. The key difference lies in condition monitoring's focus on current equipment health versus predictive maintenance's emphasis on future failure prediction and maintenance planning.

Technologies Used in Condition Monitoring

Condition monitoring employs technologies such as vibration analysis, ultrasound sensors, infrared thermography, and oil analysis to continuously track equipment health and detect early signs of failure. These techniques gather real-time data on machinery parameters like temperature, noise, and lubricant condition, enabling timely diagnostics and minimizing unplanned downtime. Advanced condition monitoring integrates IoT devices and machine learning algorithms to enhance accuracy and predictive capabilities in industrial maintenance.

Predictive Maintenance Tools and Techniques

Predictive maintenance tools and techniques utilize advanced sensors, machine learning algorithms, and IoT connectivity to continuously monitor equipment health and predict potential failures before they occur. Techniques such as vibration analysis, thermal imaging, oil analysis, and ultrasonic testing provide real-time data that enables accurate forecasting of machinery condition and optimal maintenance scheduling. These tools enhance operational efficiency, reduce downtime, and extend asset lifespan by facilitating data-driven maintenance decisions over traditional condition monitoring methods.

Benefits of Implementing Condition Monitoring

Condition monitoring significantly enhances equipment reliability by continuously tracking key parameters such as vibration, temperature, and pressure to detect early signs of wear or failure. This proactive approach reduces unplanned downtime, minimizes maintenance costs, and extends asset lifespan through timely interventions. Implementing condition monitoring supports data-driven decision-making, improving operational efficiency and reducing the risk of catastrophic equipment failures.

Advantages of Predictive Maintenance in Industry

Predictive maintenance leverages real-time data and advanced analytics to anticipate equipment failures, significantly reducing unplanned downtime and maintenance costs in industrial settings. This approach enhances asset lifespan and operational efficiency by scheduling interventions only when necessary, based on precise condition indicators. Integration of IoT sensors and AI-driven diagnostics in predictive maintenance enables proactive decision-making, optimizing resource allocation and minimizing production disruptions.

Comparing Use Cases: Condition Monitoring vs Predictive Maintenance

Condition monitoring continuously tracks equipment health by measuring parameters like vibration, temperature, and pressure to detect anomalies in real time. Predictive maintenance uses data analytics and machine learning algorithms on historical and current condition data to forecast potential failures and schedule maintenance before breakdowns occur. While condition monitoring is ideal for immediate fault detection, predictive maintenance excels in optimizing maintenance schedules and reducing downtime by accurately predicting asset lifespan.

Choosing the Right Approach for Your Mechanical Systems

Condition monitoring gathers real-time data from mechanical systems using sensors to detect signs of wear or failure, enabling timely interventions based on current equipment status. Predictive maintenance analyzes historical and real-time data with advanced algorithms to forecast future failures, allowing maintenance to be scheduled proactively before breakdowns occur. Selecting the right approach depends on system complexity, operational criticality, data availability, and maintenance resources to optimize equipment uptime and reduce costs effectively.

Vibration Analysis

Vibration analysis, a key technique in condition monitoring, enables predictive maintenance by detecting early signs of machinery faults to prevent unexpected failures.

Thermography

Thermography-based condition monitoring detects early equipment faults by identifying thermal anomalies, enhancing predictive maintenance accuracy and preventing unexpected failures.

Oil Debris Analysis

Oil debris analysis in condition monitoring detects wear particles to assess equipment health, enabling predictive maintenance to prevent failures by forecasting potential issues.

Fault Diagnosis

Fault diagnosis in condition monitoring identifies equipment abnormalities through real-time data analysis, while predictive maintenance uses this fault data to forecast failures and schedule proactive repairs.

Prognostics

Prognostics enhances predictive maintenance by using condition monitoring data to accurately forecast equipment failures and optimize maintenance schedules.

Reliability-Centered Maintenance (RCM)

Reliability-Centered Maintenance (RCM) integrates condition monitoring and predictive maintenance techniques to optimize asset reliability by identifying failure modes and implementing targeted maintenance strategies.

Real-Time Sensor Data

Real-time sensor data enables condition monitoring to continuously assess equipment health, while predictive maintenance leverages this data to forecast failures and schedule timely interventions.

Remaining Useful Life (RUL) Estimation

Remaining Useful Life (RUL) estimation leverages advanced condition monitoring data and machine learning algorithms to accurately predict equipment failure timelines, enhancing predictive maintenance strategies.

Machine Learning Predictive Models

Machine learning predictive models enhance predictive maintenance by analyzing real-time condition monitoring data to accurately forecast equipment failures and optimize maintenance schedules.

Failure Modes and Effects Analysis (FMEA)

Failure Modes and Effects Analysis (FMEA) enhances predictive maintenance by systematically identifying potential failure modes and their impacts, enabling more accurate condition monitoring and proactive maintenance strategies.

condition monitoring vs predictive maintenance Infographic

njnir.com

njnir.com