Haptic feedback provides users with a dynamic sense of force and motion, enabling the simulation of physical interactions in mechanical systems. Tactile feedback, in contrast, focuses on the perception of surface textures and pressure through skin mechanoreceptors, enhancing precision in manual control tasks. Integrating both feedback types in mechanical engineering designs significantly improves user experience by delivering comprehensive touch sensations.

Table of Comparison

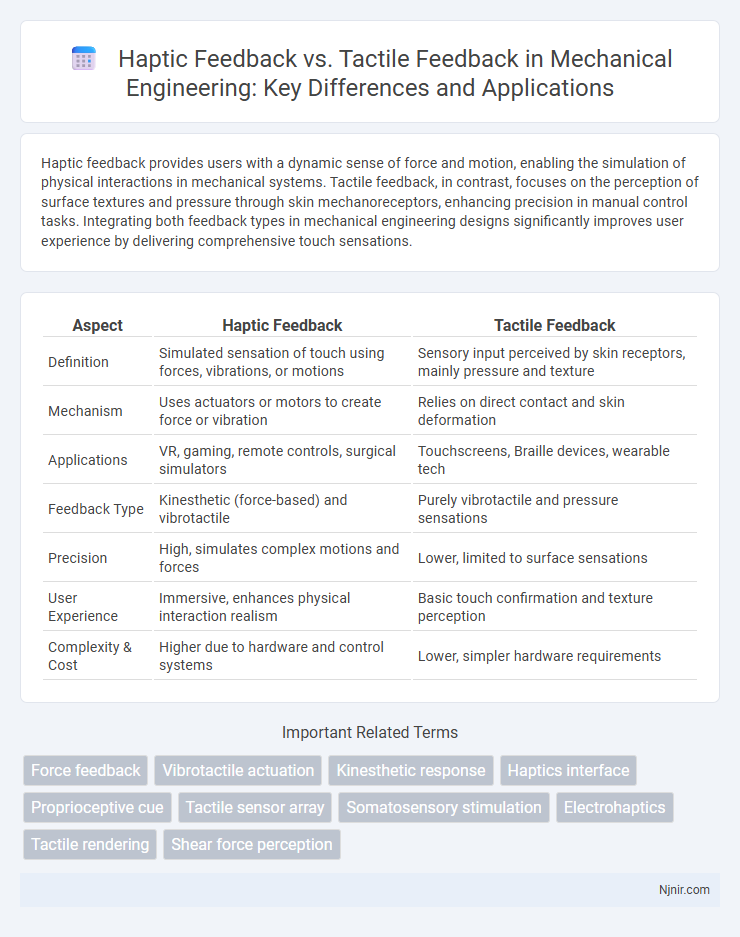

| Aspect | Haptic Feedback | Tactile Feedback |

|---|---|---|

| Definition | Simulated sensation of touch using forces, vibrations, or motions | Sensory input perceived by skin receptors, mainly pressure and texture |

| Mechanism | Uses actuators or motors to create force or vibration | Relies on direct contact and skin deformation |

| Applications | VR, gaming, remote controls, surgical simulators | Touchscreens, Braille devices, wearable tech |

| Feedback Type | Kinesthetic (force-based) and vibrotactile | Purely vibrotactile and pressure sensations |

| Precision | High, simulates complex motions and forces | Lower, limited to surface sensations |

| User Experience | Immersive, enhances physical interaction realism | Basic touch confirmation and texture perception |

| Complexity & Cost | Higher due to hardware and control systems | Lower, simpler hardware requirements |

Introduction to Haptic and Tactile Feedback in Mechanical Engineering

Haptic feedback in mechanical engineering refers to the technology that recreates the sense of touch by applying forces, vibrations, or motions to the user, enhancing interaction with machines and virtual environments. Tactile feedback is a subset of haptic feedback, concentrating specifically on stimulating the skin's mechanoreceptors through localized pressure or texture changes to convey detailed touch sensations. Innovations in actuators, sensors, and material design continue to advance the precision and realism of both haptic and tactile feedback systems in engineering applications.

Definitions: Haptic Feedback vs Tactile Feedback

Haptic feedback refers to the technology that simulates the sense of touch through forces, vibrations, or motions, enabling users to perceive virtual textures or resistance. Tactile feedback specifically involves sensations detected by the skin, such as pressure, texture, and vibration, providing direct touch information. While haptic feedback encompasses a broader range of touch-based sensations including kinesthetic inputs, tactile feedback is a subset focused solely on surface-level skin interactions.

Core Principles Behind Haptic and Tactile Technologies

Haptic feedback involves the use of mechanical vibrations or forces to simulate the sense of touch, enabling users to perceive virtual textures or interactions through kinesthetic and tactile sensations. Tactile feedback specifically targets the skin's sensory receptors by delivering localized stimuli such as pressure, vibration, or temperature changes to evoke detailed touch sensations. Both technologies rely on advanced sensors, actuators, and signal processing algorithms to accurately replicate touch experiences, enhancing immersion and user interaction in virtual reality, gaming, and wearable devices.

Key Differences Between Haptic and Tactile Feedback

Haptic feedback encompasses a broader range of sensations, including vibration, force, and motion, while tactile feedback specifically refers to the sensation of touch on the skin's surface. Haptic technology typically involves complex actuators that simulate textures and shapes, whereas tactile feedback is often limited to simple vibrations or pressure points. Understanding these distinctions is crucial for applications in virtual reality, gaming, and medical devices where the quality of user interaction depends heavily on sensory accuracy.

Applications of Haptic Feedback in Mechanical Systems

Haptic feedback in mechanical systems enhances user interaction by providing precise force and vibration sensations, improving control and safety in applications such as robotic surgery, automotive controls, and virtual reality interfaces. It enables operators to feel real-time resistance and texture, facilitating more accurate manipulation of tools and machinery. These tactile sensations are critical for tasks requiring delicate adjustments and feedback, reducing errors and increasing efficiency in complex mechanical environments.

Applications of Tactile Feedback in Mechanical Engineering

Tactile feedback in mechanical engineering is extensively applied in precision assembly, enabling operators to feel minute forces and surface textures for improved accuracy and quality control. It plays a crucial role in robotic surgery, where tactile sensors provide surgeons with real-time touch sensations to enhance dexterity and reduce errors. Advanced manufacturing equipment integrates tactile feedback systems to detect tool wear and material inconsistencies, optimizing performance and maintenance schedules.

Advantages and Limitations: Haptic vs Tactile Feedback

Haptic feedback provides a broad range of sensations by engaging multiple sensory modalities, enhancing user immersion especially in virtual reality and gaming applications, but it often requires complex hardware and higher power consumption. Tactile feedback specifically targets the sense of touch on the skin, delivering precise, localized sensations beneficial for user interfaces and medical devices, though it can be limited in simulating dynamic force or texture variations compared to full haptic systems. Both technologies offer distinct advantages: haptic feedback excels in rich, multi-dimensional interaction, while tactile feedback prioritizes accuracy and simplicity, with limitations tied to cost, device complexity, and application scope.

Integration Challenges in Mechanical Design

Integration challenges in mechanical design for haptic feedback versus tactile feedback primarily revolve around space constraints and actuator complexity. Haptic feedback systems often require larger, more powerful motors or piezoelectric actuators to generate force or vibration sensations, complicating compact device designs. Tactile feedback demands precise placement of smaller actuators or microfluidic channels to simulate texture and surface variations, increasing the intricacy of sensor integration and durability considerations.

Emerging Trends in Feedback Technologies

Haptic feedback employs vibrations and motions to simulate physical interactions, enabling immersive experiences in virtual reality and wearable devices, while tactile feedback specifically targets the sensation of touch through nuanced surface textures and pressure changes. Emerging trends in feedback technologies emphasize multimodal integration, combining haptic and tactile signals to enhance user engagement and realism in applications such as remote surgery, gaming, and robotics. Advanced materials, such as electroactive polymers and ultrasonic actuators, drive innovations that deliver more precise and localized feedback, pushing the boundaries of sensory immersion.

Future Perspectives in Mechanical Interfaces

Future perspectives in mechanical interfaces highlight advancements in haptic feedback technology, enabling more precise force and vibration simulations that enhance virtual and augmented reality experiences. Tactile feedback continues evolving with the integration of biomimetic materials and micro-actuators to replicate complex skin sensations, improving user immersion and device interaction. Emerging research focuses on combining both haptic and tactile feedback to create multifunctional interfaces that offer realistic and adaptive touch responses for medical, gaming, and robotic applications.

Force feedback

Force feedback delivers precise resistance and force sensations in haptic systems, offering a more immersive and realistic interaction compared to basic tactile feedback.

Vibrotactile actuation

Vibrotactile actuation enhances haptic feedback by using precise vibrations to simulate tactile sensations, improving user interaction in virtual reality and wearable devices.

Kinesthetic response

Kinesthetic feedback provides a sense of force and movement through muscle and joint sensations, while tactile feedback primarily involves skin-based touch sensations without engaging muscle dynamics.

Haptics interface

Haptic feedback in interfaces utilizes vibration, force, and motion cues to simulate touch sensations, offering a more immersive and multidimensional user experience compared to traditional tactile feedback, which primarily involves simple surface texture or pressure recognition.

Proprioceptive cue

Haptic feedback provides comprehensive proprioceptive cues by integrating force, vibration, and motion sensations, whereas tactile feedback primarily delivers localized skin-based touch information without fully engaging the proprioceptive system.

Tactile sensor array

Tactile sensor arrays enhance haptic feedback systems by providing detailed spatial resolution of touch stimuli, enabling precise texture and pressure detection.

Somatosensory stimulation

Haptic feedback provides complex somatosensory stimulation through force, vibration, and motion cues, while tactile feedback specifically targets skin-based mechanoreceptors for detailed touch sensations.

Electrohaptics

Electrohaptics enhances haptic feedback by using electrical stimulation to provide precise tactile sensations, improving user interaction beyond traditional mechanical tactile feedback methods.

Tactile rendering

Tactile rendering simulates surface textures and fine details through precise vibration patterns, enhancing tactile feedback's realism by directly stimulating skin receptors.

Shear force perception

Shear force perception in haptic feedback enables users to detect surface texture and direction-specific cues more effectively than traditional tactile feedback.

haptic feedback vs tactile feedback Infographic

njnir.com

njnir.com