Model-based control uses mathematical models derived from physical laws to predict system behavior and optimize performance, ensuring stability and robustness in mechanical engineering applications. Data-driven control relies on real-time data and machine learning algorithms to adaptively improve system responses without explicit system models. Combining both approaches can enhance control accuracy and reliability by leveraging the strengths of model predictability and data adaptability.

Table of Comparison

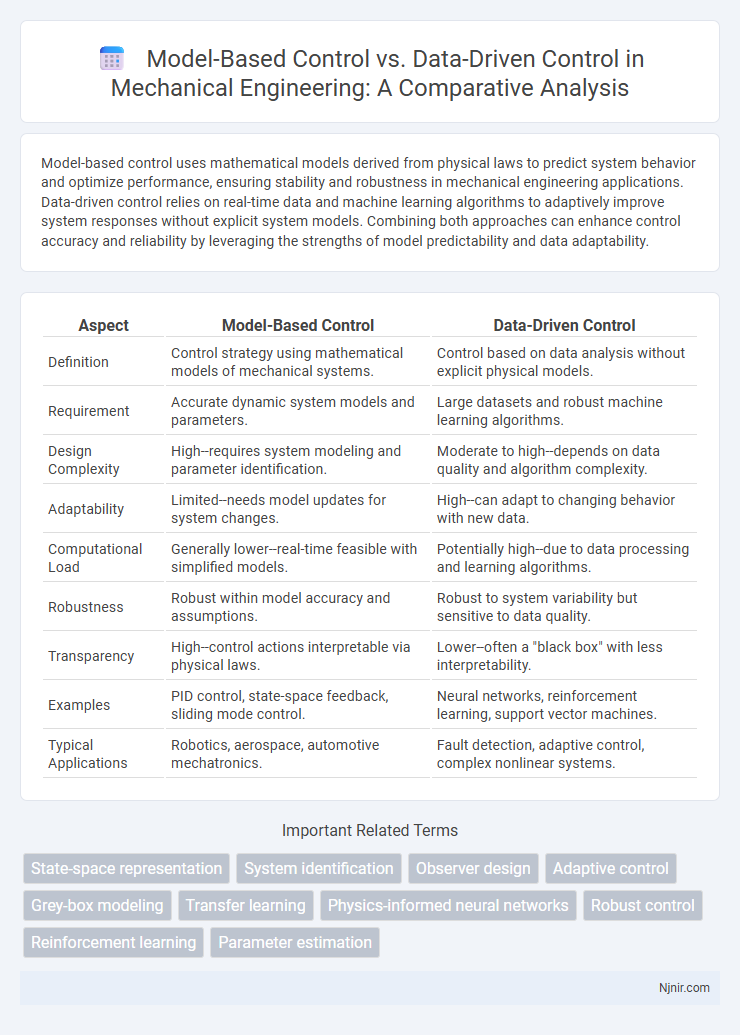

| Aspect | Model-Based Control | Data-Driven Control |

|---|---|---|

| Definition | Control strategy using mathematical models of mechanical systems. | Control based on data analysis without explicit physical models. |

| Requirement | Accurate dynamic system models and parameters. | Large datasets and robust machine learning algorithms. |

| Design Complexity | High--requires system modeling and parameter identification. | Moderate to high--depends on data quality and algorithm complexity. |

| Adaptability | Limited--needs model updates for system changes. | High--can adapt to changing behavior with new data. |

| Computational Load | Generally lower--real-time feasible with simplified models. | Potentially high--due to data processing and learning algorithms. |

| Robustness | Robust within model accuracy and assumptions. | Robust to system variability but sensitive to data quality. |

| Transparency | High--control actions interpretable via physical laws. | Lower--often a "black box" with less interpretability. |

| Examples | PID control, state-space feedback, sliding mode control. | Neural networks, reinforcement learning, support vector machines. |

| Typical Applications | Robotics, aerospace, automotive mechatronics. | Fault detection, adaptive control, complex nonlinear systems. |

Introduction to Model-Based and Data-Driven Control

Model-based control relies on mathematical models to predict system behavior and design controllers, optimizing performance through system dynamics and parameters. Data-driven control utilizes real-time data and machine learning techniques to adapt and improve control policies without explicit reliance on physical models. Both approaches address complex control problems, but model-based control excels in well-understood systems, while data-driven control handles uncertainties and nonlinearities more effectively.

Fundamental Principles of Model-Based Control

Model-based control relies on mathematical representations of system dynamics, using differential equations and physical laws to predict and regulate behavior. It emphasizes accurate system modeling for controller design, often employing state-space or transfer function models to achieve stability and performance objectives. Parameter estimation and system identification are crucial for refining the model, enabling precise control through techniques like PID, MPC, or LQR.

Core Concepts of Data-Driven Control

Data-driven control leverages historical data and real-time measurements to design control strategies without requiring a detailed mathematical model of the system, emphasizing system identification and adaptive algorithms. Techniques such as reinforcement learning, neural networks, and iterative learning control enable controllers to improve performance by continuously updating based on observed system behavior. This core concept contrasts with model-based control, which relies on precise system models, making data-driven control highly effective in complex or poorly understood environments.

Comparative Advantages in Mechanical Systems

Model-based control in mechanical systems leverages precise mathematical representations of system dynamics, enabling accurate predictions and robust stability under varying operating conditions. Data-driven control harnesses real-time sensor data and machine learning algorithms to adaptively optimize performance without requiring a detailed physical model, making it effective in complex or nonlinear systems with uncertain parameters. Combining both approaches can enhance robustness and adaptability, especially in applications like robotics and automotive systems where system models may be partially known or subject to change.

Limitations and Challenges in Both Approaches

Model-based control faces challenges such as model inaccuracies, parameter uncertainties, and the high computational cost of real-time implementation, especially in complex or nonlinear systems. Data-driven control struggles with the need for large, high-quality datasets, potential overfitting, and limited interpretability, which can hinder reliability and generalization to unseen scenarios. Both approaches require careful handling of noise, disturbances, and dynamic variations to achieve robust and stable control performance.

Applications in Robotics and Automation

Model-based control in robotics relies on mathematical models of system dynamics to achieve precise motion planning, trajectory tracking, and stability control, making it ideal for applications requiring high accuracy and predictability, such as industrial robotic arms and autonomous vehicles. Data-driven control leverages machine learning algorithms and sensor data for adaptive and robust decision-making, excelling in unstructured or dynamic environments like robotic manipulation in unknown terrains or human-robot interaction. Combining both approaches enhances performance by enabling robots and automation systems to adapt to uncertainties while maintaining model-informed precision in complex tasks.

Handling Uncertainties and System Nonlinearities

Model-based control leverages precise mathematical representations of system dynamics, enabling robust handling of uncertainties through adaptive or robust control techniques tailored to known system nonlinearities. Data-driven control relies on empirical data to capture system behavior, accommodating high degrees of uncertainty and complex nonlinearities without explicit model formulation, often using machine learning algorithms. Combining these approaches enhances performance by integrating model knowledge with real-time data adaptation, effectively managing uncertainties and nonlinear system responses.

Integration of Hybrid Control Strategies

Hybrid control strategies combine model-based control's precision and interpretability with data-driven control's adaptability by integrating mathematical models with machine learning algorithms. This integration enhances system robustness and performance in complex environments by leveraging real-time data to update models and optimize control actions dynamically. Applications in autonomous vehicles and smart grids demonstrate significant improvements in efficiency and resilience through hybrid control implementation.

Future Trends in Control Methods

Future trends in control methods highlight a convergence between model-based control and data-driven control, leveraging hybrid approaches that combine physical system models with machine learning algorithms to improve adaptability and robustness. Advances in artificial intelligence and real-time data analytics enable predictive control systems to handle complex, nonlinear dynamics with greater accuracy. The integration of digital twins and edge computing is driving enhanced decision-making capabilities, facilitating real-time optimization and fault diagnosis in industrial automation and autonomous systems.

Conclusion and Recommendations

Model-based control offers precise system understanding by leveraging physical laws and mathematical models, ensuring robustness in predictable environments. Data-driven control excels in handling complex, nonlinear systems with abundant data but may lack interpretability and stability guarantees. Integrating model-based approaches with data-driven techniques is recommended to enhance adaptability while maintaining reliability and performance in dynamic applications.

State-space representation

Model-based control utilizes explicit state-space representations derived from physical system dynamics, whereas data-driven control infers state-space models directly from observed input-output data without prior knowledge of system equations.

System identification

Model-based control relies on system identification using mathematical models derived from physical principles, while data-driven control employs algorithms that extract system behavior directly from empirical data without explicit model formulation.

Observer design

Observer design in model-based control relies on accurate system models to estimate states, whereas data-driven control uses real-time data to adapt observers without explicit models.

Adaptive control

Adaptive control integrates model-based control's reliance on system dynamics with data-driven control's real-time learning to optimize performance under changing conditions.

Grey-box modeling

Grey-box modeling combines physical system knowledge with data-driven parameter tuning, enhancing model-based control accuracy while retaining interpretability compared to purely data-driven control.

Transfer learning

Model-based control leverages system dynamics for precise transfer learning adaptation, while data-driven control relies on large datasets to generalize policies but demands extensive retraining for new tasks.

Physics-informed neural networks

Physics-informed neural networks combine model-based control's reliance on physical laws with data-driven control's adaptability, enhancing accuracy and efficiency in dynamic system management.

Robust control

Model-based control leverages system dynamics and uncertainty models to ensure robust performance under varying conditions, whereas data-driven control relies on empirical data patterns, often requiring extensive datasets to achieve comparable robustness.

Reinforcement learning

Reinforcement learning combines model-based control's predictive dynamics with data-driven control's adaptability to optimize decision-making in complex, uncertain environments.

Parameter estimation

Model-based control relies on precise parameter estimation from system dynamics for accurate predictions, while data-driven control estimates parameters directly from datasets using machine learning techniques to adapt to complex or unknown system behaviors.

Model-based control vs Data-driven control Infographic

njnir.com

njnir.com