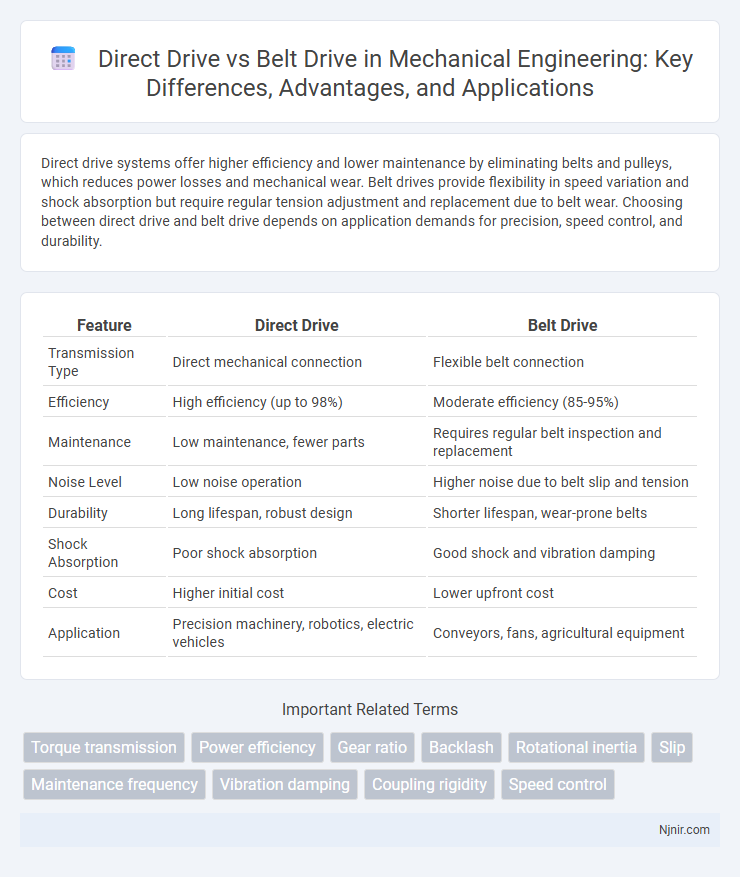

Direct drive systems offer higher efficiency and lower maintenance by eliminating belts and pulleys, which reduces power losses and mechanical wear. Belt drives provide flexibility in speed variation and shock absorption but require regular tension adjustment and replacement due to belt wear. Choosing between direct drive and belt drive depends on application demands for precision, speed control, and durability.

Table of Comparison

| Feature | Direct Drive | Belt Drive |

|---|---|---|

| Transmission Type | Direct mechanical connection | Flexible belt connection |

| Efficiency | High efficiency (up to 98%) | Moderate efficiency (85-95%) |

| Maintenance | Low maintenance, fewer parts | Requires regular belt inspection and replacement |

| Noise Level | Low noise operation | Higher noise due to belt slip and tension |

| Durability | Long lifespan, robust design | Shorter lifespan, wear-prone belts |

| Shock Absorption | Poor shock absorption | Good shock and vibration damping |

| Cost | Higher initial cost | Lower upfront cost |

| Application | Precision machinery, robotics, electric vehicles | Conveyors, fans, agricultural equipment |

Introduction to Drive Systems in Mechanical Engineering

Direct drive systems transmit power directly from the motor to the load, offering higher efficiency and reduced mechanical losses compared to belt drive systems. Belt drive systems employ flexible belts and pulleys to transfer motion, providing advantages in shock absorption and tolerance to misalignment but typically lower energy efficiency. Understanding the trade-offs between torque transmission, maintenance requirements, and system complexity is crucial for selecting the appropriate drive system in mechanical engineering applications.

Fundamental Principles of Direct Drive and Belt Drive

Direct drive systems transmit torque directly from the motor to the load without intermediary components, maximizing energy efficiency and reducing mechanical losses. Belt drive systems use a flexible belt to transfer motion between pulleys, allowing for speed variation and shock absorption but introducing potential slippage and wear. The fundamental principle of direct drive centers on eliminating transmission elements to enhance precision, while belt drive prioritizes versatility and cushioning in power transfer.

Mechanical Efficiency Comparison: Direct vs Belt Drive

Direct drive systems exhibit higher mechanical efficiency due to the elimination of intermediary components, reducing energy loss from friction and slippage commonly found in belt drives. Belt drives typically experience efficiency losses ranging from 5% to 15% due to belt elasticity, misalignment, and slip, whereas direct drives can achieve efficiencies above 95%. This superior efficiency in direct drives translates to improved power transmission, lower maintenance costs, and enhanced performance in applications such as electric vehicles and industrial machinery.

Torque Transmission and Power Handling Capabilities

Direct drive systems offer superior torque transmission due to the elimination of intermediary components, resulting in minimal power loss and higher efficiency. Belt drive systems, while flexible and easier to maintain, experience torque reduction and potential slippage under heavy loads, limiting their power handling capabilities. High-torque applications typically favor direct drive designs for consistent and reliable power delivery.

Maintenance Requirements and Lifecycle Costs

Direct drive systems typically require less maintenance than belt drive systems due to fewer moving parts and no belts that can wear out, stretch, or slip. Belt drive setups often incur higher lifecycle costs from regular belt replacements, tension adjustments, and potential misalignment issues. The overall durability and lower maintenance frequency of direct drive motors can result in reduced downtime and cost savings over their operational lifespan.

Noise, Vibration, and Operational Smoothness

Direct drive systems offer superior noise reduction and minimal vibration due to the absence of intermediary components, resulting in smoother and quieter operation. Belt drive mechanisms generate higher noise levels and vibration because of belt tension and slippage, impacting overall operational smoothness. Precision engineering in direct drive technology enhances stability and consistent torque delivery, making it ideal for applications demanding quiet and vibration-free performance.

Space and Design Flexibility Considerations

Direct drive systems offer superior space efficiency by eliminating bulky belts and pulleys, resulting in a more compact and streamlined design suitable for confined or intricate applications. Belt drive systems require additional space to accommodate pulleys and belt tensioning mechanisms, which can constrain design flexibility and complicate layouts in tight environments. Choosing direct drive enhances design adaptability, enabling integration into innovative, space-limited setups without compromising performance.

Application Suitability: Industrial and Consumer Use Cases

Direct drive systems excel in industrial applications requiring high precision, low maintenance, and efficient power transfer, making them ideal for CNC machines, robotics, and medical devices. Belt drive systems offer cost-effective, flexible solutions well-suited for consumer products such as home appliances and entry-level treadmill motors due to their shock absorption and ease of replacement. Industrial environments prioritize the durability and torque characteristics of direct drives, while consumer use cases benefit from the quieter operation and lower initial costs of belt drives.

Energy Consumption and System Performance

Direct drive systems deliver higher energy efficiency by eliminating the losses associated with belt friction and slippage, resulting in lower power consumption compared to belt drive systems. Belt drives require regular maintenance to maintain optimal tension and alignment, which can decrease overall system performance and increase downtime. Direct drive motors offer enhanced precision and reliability, making them ideal for applications demanding consistent torque and speed control with reduced energy waste.

Future Trends and Technological Innovations in Drive Systems

Direct drive systems are increasingly favored in future trends due to their higher efficiency, reduced maintenance requirements, and superior precision in applications such as electric vehicles and robotics. Innovations in magnetic bearing technology and integrated sensor feedback enhance the performance and durability of direct drives, pushing their adoption beyond traditional industrial uses. Belt drive systems evolve with advanced composite materials and smart tensioning mechanisms, improving their reliability and energy efficiency while maintaining cost-effectiveness for mid-range torque applications.

Torque transmission

Direct drive systems provide higher torque transmission efficiency and reduced power loss compared to belt drive systems due to the elimination of belt slippage and tension variations.

Power efficiency

Direct drive systems deliver higher power efficiency than belt drive systems due to reduced energy loss from friction and fewer mechanical components.

Gear ratio

Direct drive systems offer a 1:1 gear ratio for immediate power transfer, while belt drive systems provide variable gear ratios that enhance torque and speed control.

Backlash

Direct drive systems exhibit minimal backlash compared to belt drive systems due to the absence of intermediary components, resulting in higher precision and responsiveness.

Rotational inertia

Direct drive systems exhibit lower rotational inertia compared to belt drive systems, resulting in faster acceleration and more precise speed control.

Slip

Direct drive systems eliminate slip by connecting components directly, while belt drive systems are prone to slip due to belt tension and wear variations.

Maintenance frequency

Direct drive systems require significantly less frequent maintenance than belt drive systems due to fewer moving parts and reduced wear.

Vibration damping

Direct drive systems offer superior vibration damping compared to belt drive systems due to their reduced mechanical components and direct torque transmission.

Coupling rigidity

Direct drive systems offer higher coupling rigidity than belt drive systems, resulting in improved torque transmission and reduced vibration.

Speed control

Direct drive systems offer superior speed control accuracy and faster response times compared to belt drive systems, which may experience slippage and delayed adjustments.

Direct drive vs belt drive Infographic

njnir.com

njnir.com