Ductile iron offers superior strength and flexibility compared to traditional cast iron due to its nodular graphite structure, which enhances impact resistance and durability under stress. Cast iron, characterized by its brittle nature and higher compressive strength, is more susceptible to cracking under tensile loads, making it ideal for static applications with minimal dynamic stress. The choice between ductile iron and cast iron depends on the specific mechanical requirements, with ductile iron favored for components requiring toughness and cast iron preferred for wear resistance and vibration damping.

Table of Comparison

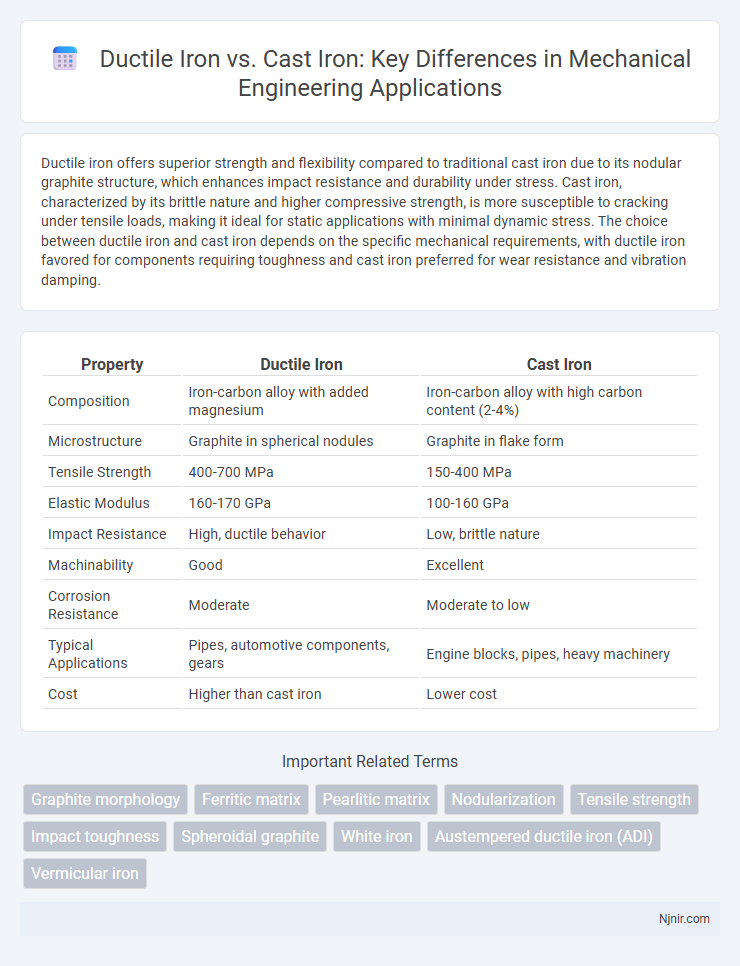

| Property | Ductile Iron | Cast Iron |

|---|---|---|

| Composition | Iron-carbon alloy with added magnesium | Iron-carbon alloy with high carbon content (2-4%) |

| Microstructure | Graphite in spherical nodules | Graphite in flake form |

| Tensile Strength | 400-700 MPa | 150-400 MPa |

| Elastic Modulus | 160-170 GPa | 100-160 GPa |

| Impact Resistance | High, ductile behavior | Low, brittle nature |

| Machinability | Good | Excellent |

| Corrosion Resistance | Moderate | Moderate to low |

| Typical Applications | Pipes, automotive components, gears | Engine blocks, pipes, heavy machinery |

| Cost | Higher than cast iron | Lower cost |

Introduction to Ductile Iron and Cast Iron

Ductile iron, also known as nodular cast iron, features graphite nodules that enhance its flexibility and toughness, making it ideal for applications requiring high impact resistance and durability. Cast iron, commonly classified as gray cast iron, contains flake graphite that provides excellent compressive strength and good machinability but is more brittle compared to ductile iron. The distinct microstructures of ductile iron and cast iron influence their mechanical properties and suitability for various industrial uses such as automotive parts, pipes, and machinery components.

Composition and Microstructure Differences

Ductile iron contains spherical graphite nodules formed by adding magnesium or cerium to the molten iron, which improves its ductility and toughness compared to cast iron. Cast iron features carbon primarily as flaky graphite within a pearlitic or ferritic matrix, leading to increased brittleness and lower tensile strength. The microstructure differences result from varying alloying elements and cooling rates, with ductile iron exhibiting a more uniform and flexible microstructure suited for impact-resistant applications.

Mechanical Properties Comparison

Ductile iron exhibits superior tensile strength, typically ranging from 60,000 to 100,000 psi, compared to gray cast iron's 20,000 to 40,000 psi, due to its nodular graphite structure that enhances ductility and impact resistance. The elongation percentage in ductile iron often reaches 10-30%, significantly higher than the brittle cast iron's 1-3%, making it more suitable for applications requiring flexibility and toughness. Hardness values for ductile iron range from 170 to 250 HB, balancing wear resistance and machinability, whereas cast iron has variable hardness but generally lower impact resistance.

Manufacturing Processes

Ductile iron is produced by adding magnesium or cerium to molten iron, which modifies the graphite structure into spheroidal nodules, enhancing ductility and impact resistance. Cast iron manufacturing involves melting iron with carbon and silicon, followed by controlled solidification that forms a brittle graphite flake structure, resulting in higher compressive strength but lower tensile properties. The distinct metallurgical treatments and cooling rates in ductile iron and cast iron manufacturing significantly influence their mechanical performance and application suitability.

Applications in Mechanical Engineering

Ductile iron is extensively used in mechanical engineering for components requiring high strength, toughness, and fatigue resistance, such as gears, crankshafts, and hydraulic components. Cast iron, with its excellent compressive strength and wear resistance, is preferred for engine blocks, machine bases, and heavy-duty pipes. The superior ductility and impact resistance of ductile iron enable it to withstand dynamic loads better than brittle cast iron in many mechanical applications.

Advantages of Ductile Iron

Ductile iron offers superior strength and flexibility compared to cast iron, making it highly resistant to impact and fatigue. Its enhanced ductility allows for better performance under stress and reduces the risk of cracking in critical applications such as automotive and heavy machinery components. This material also provides improved corrosion resistance and machinability, resulting in longer service life and lower maintenance costs.

Limitations of Cast Iron

Cast iron exhibits limitations such as brittleness and low tensile strength, making it prone to cracking under impact or tension, unlike ductile iron which has enhanced ductility due to its nodular graphite structure. Its poor fatigue resistance and limited elongation reduce its suitability for applications requiring dynamic loads or flexibility. The microstructure of cast iron restricts its machinability and weldability, impacting manufacturing processes and repair options.

Cost Analysis and Material Selection

Ductile iron generally costs more upfront than traditional cast iron due to its enhanced mechanical properties and extended service life, making it a cost-effective choice for applications requiring higher strength and durability. Cast iron remains a budget-friendly option for less demanding structural components where brittleness and lower tensile strength are acceptable. Selecting between ductile iron and cast iron hinges on balancing initial material costs against long-term performance benefits, with ductile iron favored for critical load-bearing parts and cast iron suited for cost-sensitive, non-critical uses.

Performance Under Stress and Fatigue

Ductile iron exhibits superior performance under stress and fatigue due to its enhanced ductility and impact resistance, enabled by graphite nodules that reduce crack initiation and propagation. Cast iron, characterized by its brittle microstructure and flake graphite, tends to fail prematurely under cyclic loading by developing microcracks that rapidly grow under fatigue stress. The tensile strength of ductile iron typically ranges from 60,000 to 100,000 psi, significantly outperforming gray cast iron, which generally has tensile strength between 20,000 and 60,000 psi, making ductile iron more suitable for dynamic and high-load applications.

Future Trends in Iron Alloy Usage

Rising demand for lightweight and high-strength materials drives increased adoption of ductile iron in automotive and infrastructure sectors due to its superior tensile strength and ductility compared to traditional gray cast iron. Advancements in metallurgical techniques and alloy compositions enable enhanced wear resistance and machinability, expanding ductile iron applications into renewable energy and advanced manufacturing industries. Environmental regulations and sustainability goals promote the development of eco-friendly iron alloys with improved recyclability and lower carbon footprints, positioning ductile iron as a key material in future iron alloy innovations.

Graphite morphology

Ductile iron features spherical graphite nodules that enhance strength and ductility, while cast iron contains flaky graphite that increases brittleness and reduces tensile strength.

Ferritic matrix

Ductile iron features a ferritic matrix that provides enhanced ductility and toughness compared to the predominantly pearlitic matrix of cast iron, optimizing its performance for impact-resistant applications.

Pearlitic matrix

Ductile iron with a pearlitic matrix offers higher tensile strength and improved wear resistance compared to cast iron's predominantly brittle pearlitic structure.

Nodularization

Nodularization in ductile iron enhances its tensile strength and ductility by transforming graphite flakes into spherical nodules, contrasting with the brittle graphite flakes found in conventional cast iron.

Tensile strength

Ductile iron exhibits significantly higher tensile strength, typically ranging from 60,000 to 100,000 psi, compared to cast iron's tensile strength of 20,000 to 60,000 psi.

Impact toughness

Ductile iron exhibits significantly higher impact toughness compared to cast iron due to its graphite nodules that enhance energy absorption and resistance to fracture.

Spheroidal graphite

Ductile iron contains spheroidal graphite that enhances its tensile strength and ductility compared to the flake graphite structure in cast iron, resulting in superior impact resistance and flexibility.

White iron

White iron is a hard, brittle form of cast iron distinguished by its high carbon content as cementite, offering superior wear resistance compared to ductile iron, which contains nodular graphite for enhanced ductility and toughness.

Austempered ductile iron (ADI)

Austempered ductile iron (ADI) offers superior strength, toughness, and wear resistance compared to traditional cast iron due to its unique austempering heat treatment that produces a bainitic microstructure.

Vermicular iron

Vermicular iron, characterized by its worm-like graphite morphology, offers a unique balance of ductility and cast iron's thermal conductivity, enhancing mechanical strength and corrosion resistance compared to traditional ductile iron and cast iron.

Ductile iron vs cast iron Infographic

njnir.com

njnir.com