Microfluidics involves the precise manipulation of fluids at the microliter to picoliter scale, enabling rapid chemical reactions and high-throughput analysis in compact systems. Macrofluidics handles larger volumes with conventional fluid dynamics principles, suitable for industrial applications such as HVAC systems and hydraulic machinery. The integration of microfluidic technology enhances efficiency and control in processes where space and sample volume are limited.

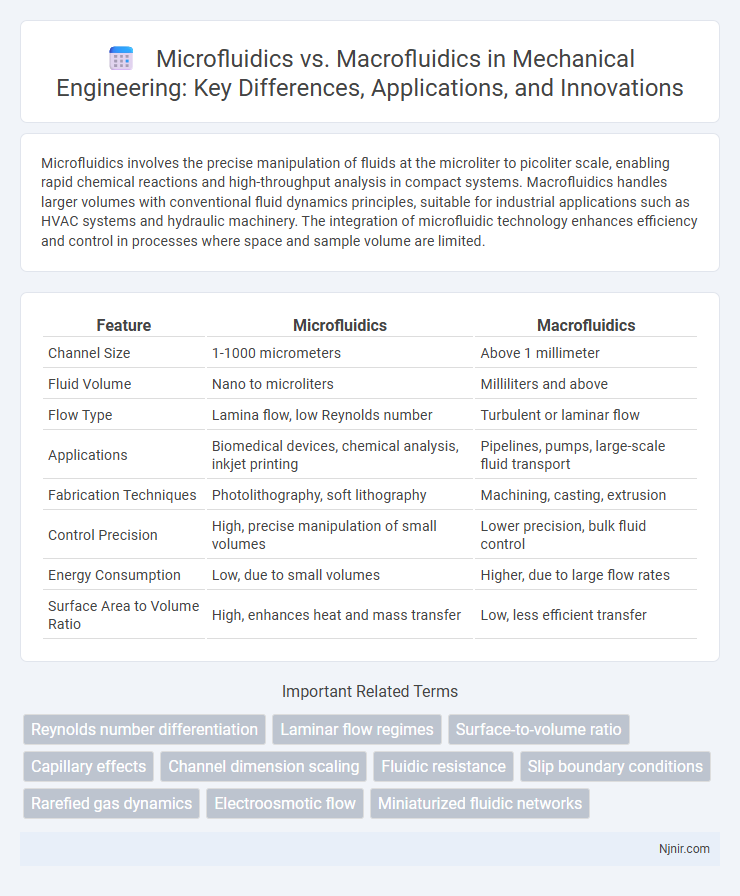

Table of Comparison

| Feature | Microfluidics | Macrofluidics |

|---|---|---|

| Channel Size | 1-1000 micrometers | Above 1 millimeter |

| Fluid Volume | Nano to microliters | Milliliters and above |

| Flow Type | Lamina flow, low Reynolds number | Turbulent or laminar flow |

| Applications | Biomedical devices, chemical analysis, inkjet printing | Pipelines, pumps, large-scale fluid transport |

| Fabrication Techniques | Photolithography, soft lithography | Machining, casting, extrusion |

| Control Precision | High, precise manipulation of small volumes | Lower precision, bulk fluid control |

| Energy Consumption | Low, due to small volumes | Higher, due to large flow rates |

| Surface Area to Volume Ratio | High, enhances heat and mass transfer | Low, less efficient transfer |

Introduction to Fluidics in Mechanical Engineering

Microfluidics involves the precise control and manipulation of fluids at the micrometer scale, enabling high sensitivity and rapid analysis essential in mechanical engineering applications such as lab-on-a-chip devices and micro heat exchangers. Macrofluidics deals with fluid behavior at a larger scale, focusing on traditional fluid dynamics principles applied to systems like pipelines, pumps, and engines. Understanding the contrast between microfluidics and macrofluidics aids mechanical engineers in designing efficient fluidic systems optimized for scale-specific performance and functionality.

Fundamentals of Microfluidics

Microfluidics studies fluid behavior at the microscale, where laminar flow dominates and surface forces like capillarity and electrokinetics significantly influence fluid dynamics. Unlike macrofluidics, which deals with turbulent flow and inertial forces in larger channels, microfluidic systems operate under low Reynolds numbers, enabling precise control of tiny volumes. This fundamental difference allows microfluidics to excel in applications such as lab-on-a-chip devices, single-cell analysis, and rapid chemical reactions.

Fundamentals of Macrofluidics

Macrofluidics studies fluid behavior at larger scales where inertial forces dominate over surface tension, governed by the Navier-Stokes equations under turbulent or laminar flow conditions. It emphasizes classical fluid dynamics principles such as pressure, velocity profiles, and Reynolds number to predict flow patterns in pipes, channels, and open systems. Understanding viscosity, flow rate, and turbulence characteristics is crucial for applications involving industrial fluid transport and large-scale hydraulic systems.

Key Differences Between Microfluidics and Macrofluidics

Microfluidics involves the precise manipulation of fluids at the microliter to picoliter scale within channels typically less than 100 micrometers in size, enabling high-resolution control in applications like lab-on-a-chip devices and biomedical diagnostics. Macrofluidics, by contrast, deals with fluid dynamics at the milliliter scale and above, commonly applied in industrial processes, plumbing, and large-scale fluid transport. Key differences include scale-dependent phenomena such as laminar flow dominance and surface tension effects in microfluidics, which are negligible in macrofluidics where turbulent flow and gravitational forces predominate.

Scale Effects on Fluid Behavior: Micro vs Macro

Microfluidics exhibits unique scale-dependent phenomena such as laminar flow dominance, high surface-to-volume ratios, and pronounced capillary forces, which significantly influence fluid behavior differently than in macrofluidics. In contrast, macrofluidics typically experiences turbulent flow, lower surface effects, and gravitational forces that govern fluid dynamics at larger scales. These fundamental differences in scale effects lead to distinct applications and design considerations in fields like biomedical engineering and chemical processing.

Design and Fabrication Techniques

Microfluidics relies on precise photolithography, soft lithography, and micro-molding techniques to create microscale channels, enabling accurate fluid control within dimensions typically under 100 micrometers. Macrofluidics employs conventional machining, injection molding, and extrusion processes suitable for larger-scale channels that handle higher volumes with millimeter to centimeter-scale dimensions. Design optimization in microfluidics emphasizes minimizing fluidic resistance and enhancing surface-to-volume ratios, while macrofluidics prioritizes structural robustness and ease of assembly for large-scale fluid handling systems.

Applications of Microfluidics in Industry

Microfluidics enables precise manipulation of tiny fluid volumes, revolutionizing industries such as pharmaceuticals for drug screening, diagnostics for point-of-care testing, and chemical engineering for microscale reaction control. Its applications extend to biotechnology, where lab-on-a-chip devices streamline DNA analysis and protein synthesis, enhancing throughput and reducing costs. The technology's ability to conduct high-throughput screening, improve mixing efficiency, and enable automation makes it indispensable in advancing microscale industrial processes beyond the capabilities of traditional macrofluidics.

Applications of Macrofluidics in Industry

Macrofluidics plays a crucial role in various industrial applications, including large-scale fluid transport, chemical processing, and thermal management systems. Industries such as oil and gas, water treatment, and automotive manufacturing rely on macrofluidic systems for efficient pipeline flow, filtration, and heat exchangers. These applications prioritize handling high volumes of fluids, enabling large-scale operations and process optimization.

Challenges and Limitations of Microfluidics and Macrofluidics

Microfluidics faces challenges such as complex fabrication processes, limited throughput, and difficulty in integrating multiple functions on a single chip, which restrict large-scale applications. Macrofluidics, while handling higher volumes efficiently, struggles with limited precision and slower response times in complex fluid manipulation tasks. Both systems encounter issues in scalability, material compatibility, and maintaining fluid control under varied operational conditions.

Future Trends in Fluidic Technologies

Microfluidics is advancing toward highly integrated lab-on-a-chip systems enabling precise control and manipulation of fluids at the microscale, driving innovations in medical diagnostics and drug delivery. Macrofluidics continues to evolve with enhanced computational fluid dynamics and scalable designs, improving applications in energy systems, aerospace, and large-scale industrial processes. Future trends emphasize hybrid fluidics combining micro and macro scales to optimize performance, efficiency, and real-time monitoring in diverse sectors.

Reynolds number differentiation

Reynolds number in microfluidics typically remains below 1, indicating laminar flow, whereas in macrofluidics it often exceeds 2000, leading to turbulent flow.

Laminar flow regimes

Microfluidics operates predominantly under laminar flow regimes with low Reynolds numbers below 2300, enabling precise fluid control at microscale channels, whereas macrofluidics often encounters turbulent flow with higher Reynolds numbers that complicate flow predictability and mixing.

Surface-to-volume ratio

Microfluidics exhibits a significantly higher surface-to-volume ratio compared to macrofluidics, enhancing mass and heat transfer rates in microscale fluidic systems.

Capillary effects

Capillary effects dominate microfluidics by enabling fluid manipulation at microscale through surface tension, while macrofluidics rely primarily on pressure-driven flow where capillary forces are negligible.

Channel dimension scaling

Microfluidics involves fluid flow in channels with dimensions typically ranging from 1 to 100 micrometers, enabling precise control and manipulation at the microscale, while macrofluidics deals with larger channels above 1 millimeter, suitable for higher volume flows but with less sensitivity to surface effects.

Fluidic resistance

Microfluidic systems exhibit significantly higher fluidic resistance due to their microscale channel dimensions compared to macrofluidic systems, impacting flow rates and pressure requirements.

Slip boundary conditions

Slip boundary conditions significantly influence flow behavior in microfluidics by reducing friction at fluid-solid interfaces, unlike in macrofluidics where no-slip conditions predominantly apply due to larger scale effects.

Rarefied gas dynamics

Rarefied gas dynamics in microfluidics reveal significant deviations from continuum assumptions seen in macrofluidics, affecting flow behavior, pressure distribution, and molecular transport at microscale dimensions.

Electroosmotic flow

Electroosmotic flow in microfluidics enables precise fluid control and rapid mixing at microscale channels, unlike macrofluidics where pressure-driven flow dominates and electroosmosis effects are minimal.

Miniaturized fluidic networks

Miniaturized fluidic networks in microfluidics enable precise control and manipulation of fluids at the microscale, offering significantly higher surface-to-volume ratios and reduced reagent consumption compared to macrofluidics used in larger-scale fluid transport systems.

Microfluidics vs macrofluidics Infographic

njnir.com

njnir.com