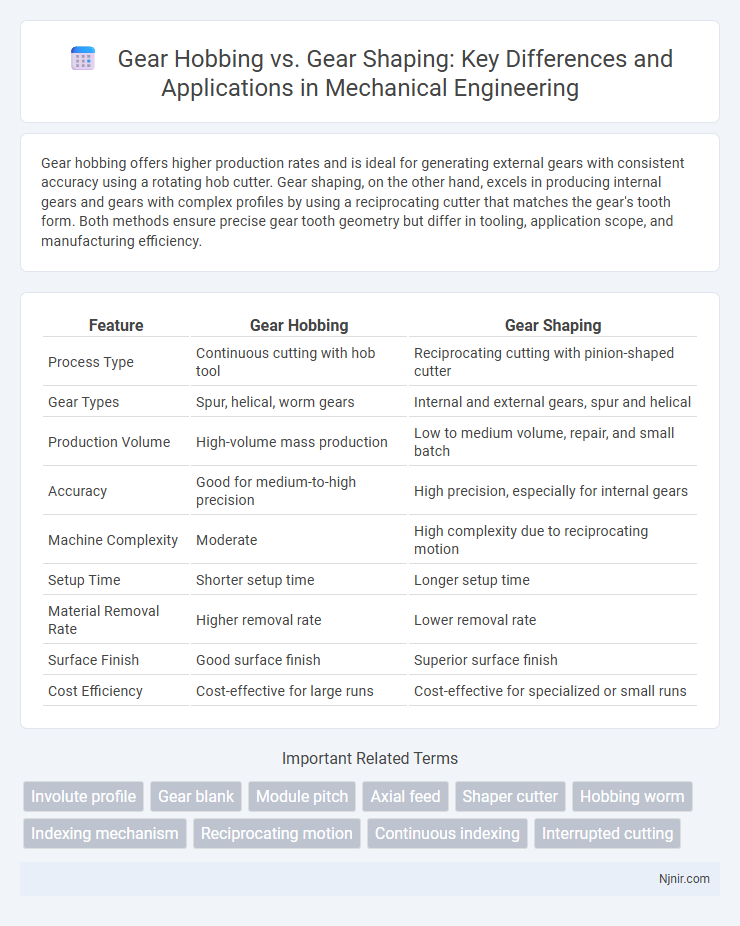

Gear hobbing offers higher production rates and is ideal for generating external gears with consistent accuracy using a rotating hob cutter. Gear shaping, on the other hand, excels in producing internal gears and gears with complex profiles by using a reciprocating cutter that matches the gear's tooth form. Both methods ensure precise gear tooth geometry but differ in tooling, application scope, and manufacturing efficiency.

Table of Comparison

| Feature | Gear Hobbing | Gear Shaping |

|---|---|---|

| Process Type | Continuous cutting with hob tool | Reciprocating cutting with pinion-shaped cutter |

| Gear Types | Spur, helical, worm gears | Internal and external gears, spur and helical |

| Production Volume | High-volume mass production | Low to medium volume, repair, and small batch |

| Accuracy | Good for medium-to-high precision | High precision, especially for internal gears |

| Machine Complexity | Moderate | High complexity due to reciprocating motion |

| Setup Time | Shorter setup time | Longer setup time |

| Material Removal Rate | Higher removal rate | Lower removal rate |

| Surface Finish | Good surface finish | Superior surface finish |

| Cost Efficiency | Cost-effective for large runs | Cost-effective for specialized or small runs |

Introduction to Gear Hobbing and Gear Shaping

Gear hobbing is a versatile and efficient method for cutting gears using a hob, which is a specialized cutting tool shaped like a worm. Gear shaping employs a reciprocating cutter that gradually cuts gear teeth by meshing with a blank, allowing for precise internal and external gear production. Both processes are fundamental in manufacturing high-quality gears, with hobbing favored for high-volume production and shaping preferred for complex or internal gears.

Fundamental Principles of Gear Hobbing

Gear hobbing operates on the principle of continuous generation, where a rotating hob and a workpiece simultaneously rotate to cut teeth progressively, creating precise helical or spur gears. The hob acts as a specialized cutting tool with a series of cutting edges arranged in a helical pattern, enabling efficient material removal with high accuracy and surface finish. This method ensures synchronized motion between tool and gear blank, resulting in consistent tooth geometry and enhanced production speed compared to gear shaping.

Core Concepts of Gear Shaping

Gear shaping uses a reciprocating cutter that progressively forms the gear teeth by cutting with a pinion-shaped tool, allowing internal and external gears to be machined with high precision. This method excels in producing gears with complex profiles and maintaining accurate tooth geometry through synchronized rotation of the cutter and gear blank. Unlike gear hobbing, which employs a continuously rotating hob, gear shaping's incremental cutting and indexing enhance flexibility for smaller or internal gear applications.

Gear Hobbing: Process Workflow and Equipment

Gear hobbing is a highly efficient gear manufacturing process that uses a specialized cutting tool called a hob to progressively cut teeth into a rotating blank. The process workflow includes mounting the gear blank and hob cutter on synchronized spindles, controlling rotation speeds to maintain precise tooth geometry, and continuous material removal until the desired gear profile is achieved. Key equipment for gear hobbing involves CNC hobbing machines with advanced controls, high-precision spindles, and adaptive feed systems to ensure accuracy and repeatability.

Gear Shaping: Process Workflow and Equipment

Gear shaping involves a cutting tool shaped like a gear that rotates in synchronization with the gear blank, creating precise internal or external gear teeth through a reciprocating motion. The process workflow includes mounting the gear blank and the shaper cutter on parallel spindles, coordinating their rotation speeds based on gear specifications, and executing multiple passes to gradually form accurate gear profiles. Equipment for gear shaping typically consists of a gear shaping machine equipped with specialized cutters, adjustable spindles, and controls for feed rate, depth of cut, and synchronization to ensure high precision and surface finish.

Comparative Analysis: Gear Accuracy and Surface Finish

Gear hobbing typically offers higher production efficiency and consistent gear accuracy due to continuous cutting action, achieving precise involute profiles with minimal deviation. Gear shaping provides superior surface finish quality by allowing controlled cutting parameters and generating gears with less surface roughness, especially beneficial for internal gears or complex geometries. Both processes achieve high dimensional accuracy, but gear hobbing excels in volume production accuracy while gear shaping delivers finer surface textures suited for specialized applications.

Production Efficiency: Speed and Batch Size Considerations

Gear hobbing offers higher production efficiency due to its continuous cutting action, enabling faster machining speeds and making it ideal for large batch sizes and mass production. Gear shaping uses a reciprocating cutting motion, resulting in slower processing times but better suitability for smaller, complex gears and lower volume production runs. For industries prioritizing speed and large-scale output, gear hobbing proves more cost-effective and time-efficient compared to the more versatile yet slower gear shaping method.

Material and Gear Type Compatibility

Gear hobbing is highly compatible with a wide range of materials, including hardened steels and non-ferrous metals, making it ideal for producing spur, helical, and worm gears with high precision and efficiency. Gear shaping is particularly effective for internal gears, splines, and gears with complex profiles, often preferred for softer materials or when cutting internal gear teeth where hobbing is less effective. Both methods can be optimized for specific gear types and materials, but gear hobbing generally excels in high-volume production with external gears, while gear shaping offers greater versatility with internal and specialized gear forms.

Cost Implications and Tooling Lifespan

Gear hobbing generally offers lower initial tooling costs and higher production efficiency compared to gear shaping, making it more cost-effective for large batch manufacturing. Tooling lifespan in gear hobbing tends to be longer due to continuous cutting action, resulting in reduced wear and maintenance frequency. Conversely, gear shaping involves intermittent cutting forces that can accelerate tool wear, increasing tooling replacement costs and downtime in comparison to hobbing.

Applications and Industry Use Cases

Gear hobbing excels in producing high-precision spur and helical gears for automotive transmissions, aerospace components, and heavy machinery, leveraging its fast cycle times and versatility in large-scale manufacturing. Gear shaping is preferred for internal and external gears with complex profiles, commonly used in aerospace actuators, precision instruments, and small batch production requiring intricate gear geometries. The automotive industry relies heavily on gear hobbing for mass production, while gear shaping serves specialized sectors like robotics and defense, where customization and accuracy are critical.

Involute profile

Gear hobbing produces more accurate involute profiles with superior surface finish compared to gear shaping, making it ideal for high-volume manufacturing of gears with consistent tooth geometry.

Gear blank

Gear hobbing efficiently produces gear blanks with continuous cutting action, while gear shaping shapes gear blanks using reciprocating cutters for intricate internal gear profiles.

Module pitch

Gear hobbing offers faster production and better surface finish but gear shaping provides superior accuracy and consistency in module pitch for complex internal gears.

Axial feed

Gear hobbing features continuous axial feed allowing faster production, whereas gear shaping employs intermittent axial feed suited for internal gears and complex profiles.

Shaper cutter

Shaper cutters used in gear shaping provide precise tooth profiles for internal and external gears, while gear hobbing employs hob cutters ideal for high-volume production of external gears with continuous cutting action.

Hobbing worm

Gear hobbing utilizes a hob resembling a worm gear, enabling continuous cutting for high-precision and efficient production compared to the reciprocating action in gear shaping.

Indexing mechanism

Gear hobbing uses continuous indexing with a hob and workpiece rotation synchronized by a gear train, while gear shaping relies on intermittent indexing where the cutter and workpiece reciprocate and rotate in timed cycles.

Reciprocating motion

Gear hobbing uses continuous rotary motion of the hob while gear shaping relies on reciprocating motion of the cutting tool for gear generation.

Continuous indexing

Gear hobbing features continuous indexing allowing faster, uninterrupted gear production, while gear shaping uses intermittent indexing resulting in slower cycle times.

Interrupted cutting

Gear hobbing offers continuous cutting ideal for high-volume production, while gear shaping involves interrupted cutting suited for internal gears and complex tooth profiles.

Gear hobbing vs gear shaping Infographic

njnir.com

njnir.com