A strain gauge measures strain by detecting changes in electrical resistance when a material deforms under stress, providing precise local strain data. A load cell, often incorporating strain gauges, converts applied force into an electrical signal to directly quantify load or weight with high accuracy. Strain gauges offer detailed strain mapping, while load cells deliver comprehensive force measurement for mechanical testing and structural monitoring.

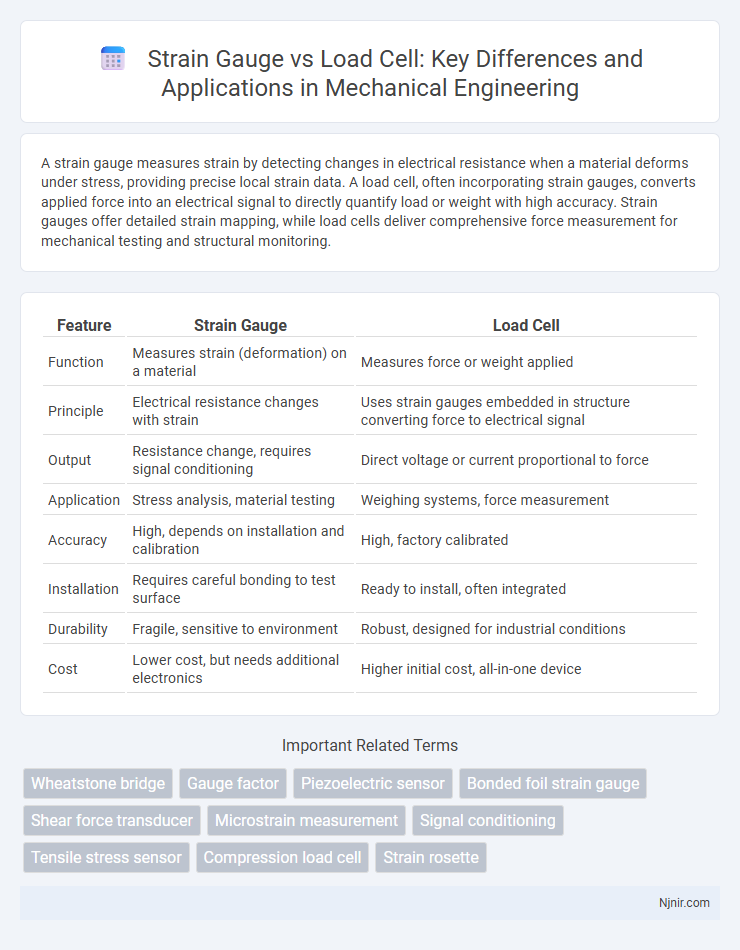

Table of Comparison

| Feature | Strain Gauge | Load Cell |

|---|---|---|

| Function | Measures strain (deformation) on a material | Measures force or weight applied |

| Principle | Electrical resistance changes with strain | Uses strain gauges embedded in structure converting force to electrical signal |

| Output | Resistance change, requires signal conditioning | Direct voltage or current proportional to force |

| Application | Stress analysis, material testing | Weighing systems, force measurement |

| Accuracy | High, depends on installation and calibration | High, factory calibrated |

| Installation | Requires careful bonding to test surface | Ready to install, often integrated |

| Durability | Fragile, sensitive to environment | Robust, designed for industrial conditions |

| Cost | Lower cost, but needs additional electronics | Higher initial cost, all-in-one device |

Introduction to Strain Gauges and Load Cells

Strain gauges measure the deformation of an object by converting mechanical strain into an electrical signal, typically using a thin conductive foil pattern bonded to the surface. Load cells are transducers that convert applied force or weight into an electrical signal, often utilizing multiple strain gauges arranged in a Wheatstone bridge configuration for accurate force measurement. Both devices play critical roles in structural health monitoring, material testing, and industrial weighing systems.

Fundamental Working Principles

Strain gauges operate by measuring the change in electrical resistance as they deform under stress, converting mechanical strain into an electrical signal. Load cells utilize strain gauges attached to a structural element, such as a metal beam, to detect force or load by measuring strain-induced resistance changes. The fundamental principle behind both devices is the piezoresistive effect, where mechanical deformation alters electrical resistance, enabling precise measurement of stress or load.

Key Components and Construction

Strain gauges consist of a thin, electrically conductive foil pattern bonded to a flexible backing, which deforms with the material to measure strain through resistance changes. Load cells incorporate multiple strain gauges mounted on a metal elastic element, often a steel or aluminum alloy beam, which deforms under load to produce a measurable electrical signal. The precision of load cells relies on the careful arrangement and wiring of strain gauges in a Wheatstone bridge configuration to enhance sensitivity and temperature compensation.

Strain Gauge vs Load Cell: Measurement Techniques

Strain gauges measure deformation by detecting changes in electrical resistance caused by strain in a material, providing highly localized and precise data on stress and force. Load cells incorporate strain gauges within a mechanical structure to convert applied force into an electrical signal, enabling direct measurement of weight or load with high accuracy and repeatability. While strain gauges require external calibration and interpretation, load cells offer integrated measurement systems optimized for practical force and weight sensing applications.

Accuracy and Sensitivity Comparison

Strain gauges offer high sensitivity by directly measuring strain changes on materials, allowing precise detection of minute deformations, but their accuracy can be influenced by temperature variations and bonding quality. Load cells, integrating strain gauges within a robust transducer housing, deliver greater overall accuracy and stability due to built-in compensation mechanisms and calibration processes. Sensitivity in load cells is typically lower than individual strain gauges but provides more reliable and repeatable measurements in practical applications.

Application Areas in Mechanical Engineering

Strain gauges are extensively used for precise measurement of stress, strain, and deformation in material testing, structural health monitoring, and fatigue analysis in mechanical engineering. Load cells find primary application in force measurement systems, including weighing scales, hydraulic testing, and robotic force feedback, where accurate load quantification is essential. Both devices are critical in industries such as aerospace, automotive, and civil engineering for ensuring safety, performance, and durability of mechanical components and structures.

Installation and Maintenance Considerations

Strain gauges require precise application on the target surface with proper surface preparation, adhesive curing, and wiring, making their installation labor-intensive and sensitive to environmental factors. Load cells offer easier installation with standardized mounting interfaces and built-in signal conditioning, reducing setup time and minimizing calibration needs during maintenance. Regular inspections are critical for strain gauges to detect adhesive degradation or wire damage, whereas load cells typically demand routine zero and span checks to ensure accuracy over time.

Cost and Durability Analysis

Strain gauges offer a cost-effective solution for measuring strain with economical sensor prices and simple installation, making them ideal for budget-sensitive applications. Load cells, while more expensive upfront due to integrated circuitry and robust construction, provide superior durability and longevity in harsh industrial environments. Evaluating total cost of ownership favors load cells in high-stress or repetitive load conditions due to reduced maintenance and replacement frequency.

Data Output and Signal Processing

Strain gauges produce raw electrical resistance changes proportional to strain, requiring precise signal conditioning such as Wheatstone bridge circuits and amplification for accurate data output. Load cells integrate strain gauges with built-in signal processors, providing calibrated, linearized voltage or digital signals compatible with data acquisition systems. Advanced load cells often offer temperature compensation and digital communication protocols like SPI or I2C, enhancing measurement reliability and simplifying signal processing.

Choosing Between Strain Gauges and Load Cells

Choosing between strain gauges and load cells depends on the application requirements such as measurement accuracy, load capacity, and environmental conditions. Strain gauges offer high sensitivity and are ideal for custom or embedded stress analysis, while load cells provide integrated and calibrated force measurement for industrial applications. Selecting the appropriate sensor involves evaluating factors like installation complexity, signal conditioning needs, and cost-effectiveness.

Wheatstone bridge

Strain gauges measure minute deformations by converting mechanical strain into electrical signals using a Wheatstone bridge circuit, while load cells utilize multiple strain gauges arranged in a Wheatstone bridge configuration to provide precise force or weight measurements.

Gauge factor

The gauge factor of a strain gauge, typically ranging from 2 to 5, directly influences its sensitivity to strain, whereas load cells rely on multiple strain gauges arranged in a Wheatstone bridge to measure force with higher accuracy and stability.

Piezoelectric sensor

Piezoelectric sensors convert mechanical stress into electrical signals with high sensitivity and fast response, making them ideal for dynamic force measurement compared to strain gauges and load cells.

Bonded foil strain gauge

Bonded foil strain gauges offer precise, reliable strain measurement by adhering directly to a surface, making them essential components in load cells for accurate force and weight sensing in industrial applications.

Shear force transducer

Shear force transducers using strain gauges provide highly accurate and sensitive measurements by detecting minute deformations in materials under shear stress, outperforming traditional load cells in precision for shear-specific applications.

Microstrain measurement

Strain gauges offer precise microstrain measurement by detecting minute deformations in materials, while load cells primarily measure force and require strain gauges as sensing elements for microstrain data.

Signal conditioning

Signal conditioning for strain gauges involves amplifying and filtering microstrain signals for accurate measurement, whereas load cells integrate built-in signal conditioning circuits to output standardized electrical signals such as voltage or current.

Tensile stress sensor

A tensile stress sensor using a strain gauge provides precise measurement of tensile forces by detecting minute deformations, whereas a load cell converts overall applied loads into electrical signals for comprehensive force analysis.

Compression load cell

Compression load cells use strain gauges to accurately measure force by detecting strain caused by applied compressive loads, providing precise and reliable weight measurement in industrial applications.

Strain rosette

Strain rosettes, consisting of multiple strain gauges arranged at specific angles, provide precise multi-directional strain measurements essential for accurate stress analysis compared to single-axis load cells.

strain gauge vs load cell Infographic

njnir.com

njnir.com