Brushed motors use physical brushes and a commutator to transfer current, which causes more friction, wear, and maintenance compared to brushless motors. Brushless motors employ electronic commutation, resulting in higher efficiency, longer lifespan, and reduced noise in mechanical engineering applications. The choice between brushed and brushless motors depends on factors such as cost, complexity, and performance requirements.

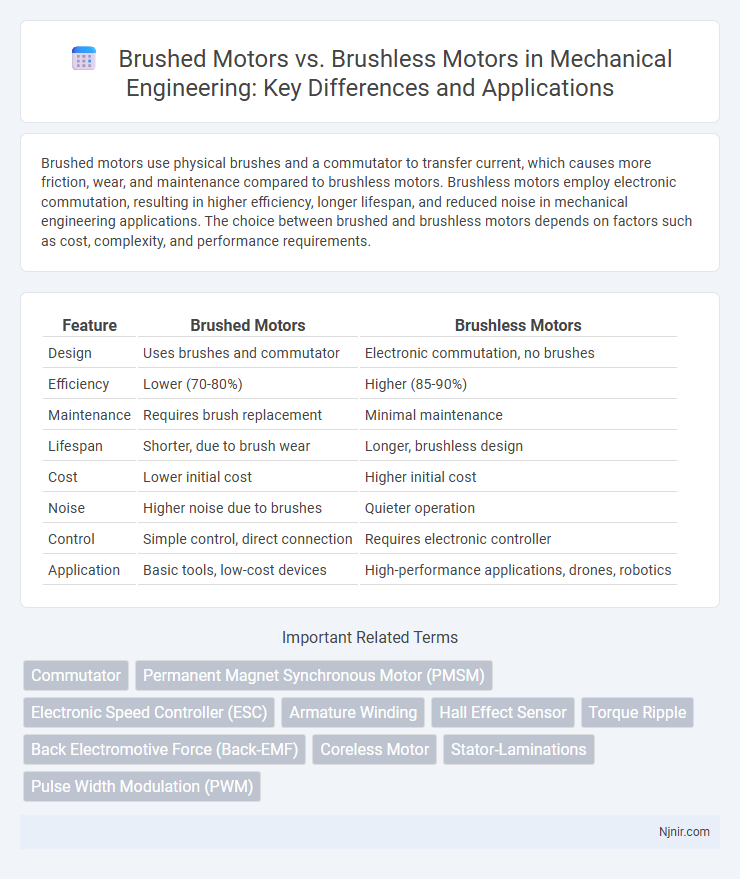

Table of Comparison

| Feature | Brushed Motors | Brushless Motors |

|---|---|---|

| Design | Uses brushes and commutator | Electronic commutation, no brushes |

| Efficiency | Lower (70-80%) | Higher (85-90%) |

| Maintenance | Requires brush replacement | Minimal maintenance |

| Lifespan | Shorter, due to brush wear | Longer, brushless design |

| Cost | Lower initial cost | Higher initial cost |

| Noise | Higher noise due to brushes | Quieter operation |

| Control | Simple control, direct connection | Requires electronic controller |

| Application | Basic tools, low-cost devices | High-performance applications, drones, robotics |

Introduction to Brushed and Brushless Motors

Brushed motors use physical brushes and a commutator to transfer electrical current, leading to mechanical wear and maintenance needs. Brushless motors utilize electronic controllers to manage current flow, resulting in higher efficiency, longer lifespan, and reduced noise. The design difference impacts performance characteristics, with brushless motors preferred in applications requiring durability and precision.

Basic Operation Principles

Brushed motors operate using mechanical brushes that transfer electric current to the rotating armature, generating torque through electromagnetic interaction with stationary magnets. In contrast, brushless motors eliminate mechanical brushes by using electronic controllers to switch current in the stator windings, resulting in more efficient, precise, and durable operation. The fundamental difference lies in the method of current delivery and commutation, which impacts performance, maintenance, and lifespan.

Key Components and Design Differences

Brushed motors feature carbon brushes and a commutator that mechanically switch current to the armature windings, while brushless motors eliminate these components by using electronic controllers to regulate current through permanent magnets and stator windings. The design of brushed motors results in more wear and maintenance due to brush friction, whereas brushless motors benefit from higher efficiency, reduced heat generation, and longer lifespan due to the absence of physical brushes. Key components in brushless motors include electronic speed controllers (ESCs), Hall effect sensors, and rotor magnets; brushed motors rely primarily on the rotor, stator, carbon brushes, and commutator for their operation.

Performance Comparison: Efficiency and Power Output

Brushless motors outperform brushed motors in efficiency by eliminating friction and voltage drops caused by brushes, achieving up to 85-90% efficiency compared to 75-80% in brushed designs. Power output in brushless motors is higher due to their ability to maintain consistent torque at varying speeds, supporting superior acceleration and sustained high-speed performance. The longer lifespan and reduced maintenance requirements of brushless motors further enhance overall operational efficiency in demanding applications.

Maintenance Requirements and Lifespan

Brushed motors require regular maintenance due to brush and commutator wear, leading to more frequent replacements and downtime. Brushless motors have longer lifespans with minimal maintenance since they use electronic controllers instead of physical brushes, reducing mechanical wear. The increased durability and reduced upkeep of brushless motors make them preferable for high-performance and continuous-operation applications.

Cost Analysis: Initial Investment vs. Long-Term Value

Brushed motors typically have a lower initial investment due to simpler design and manufacturing processes, making them cost-effective for short-term applications. Brushless motors, although more expensive upfront, offer superior efficiency, reduced maintenance costs, and longer lifespan, resulting in better long-term value. Evaluating total cost of ownership highlights brushless motors as more economical for high-performance or continuous-use scenarios despite their higher initial price.

Applications in Mechanical Engineering

Brushed motors are commonly used in low-cost, simple mechanical engineering applications such as power tools, household appliances, and automotive starters due to their ease of control and reliability at low speeds. Brushless motors offer higher efficiency, longer lifespan, and superior torque-to-weight ratios, making them ideal for precision robotics, CNC machines, drones, and electric vehicles where performance and durability are critical. The choice between brushed and brushless motors depends on factors like maintenance requirements, speed control accuracy, and operational environment in mechanical engineering designs.

Control Systems and Ease of Integration

Brushless motors offer superior control system compatibility through their electronic commutation, enabling precise speed and torque regulation ideal for advanced applications. Brushed motors rely on mechanical commutation, limiting control accuracy and increasing maintenance due to brush wear. Integration of brushless motors is simplified by built-in sensors and standardized electronic controllers, reducing wiring complexity and improving system reliability.

Common Issues and Failure Modes

Brushed motors commonly face issues such as brush wear, commutator pitting, and sparking due to friction and electrical arcing, leading to decreased efficiency and frequent maintenance. Brushless motors, while lacking brushes, can encounter problems like bearing failure, electronic controller faults, and thermal overload, which may result in sudden stoppages or reduced performance. Both motor types require monitoring for overheating and ensuring proper lubrication to prolong operational lifespan and reliability.

Environmental Impacts and Future Trends

Brushless motors offer higher energy efficiency and longer lifespan compared to brushed motors, significantly reducing electronic waste and energy consumption. The absence of brushes eliminates carbon brush dust, decreasing environmental pollution and maintenance requirements. Future trends emphasize the integration of brushless motors in electric vehicles and renewable energy systems, promoting sustainable technology advancements and lower carbon footprints.

Commutator

Brushless motors eliminate the mechanical commutator found in brushed motors, resulting in higher efficiency, reduced maintenance, and longer lifespan.

Permanent Magnet Synchronous Motor (PMSM)

Permanent Magnet Synchronous Motors (PMSMs) outperform traditional brushed motors by offering higher efficiency, precise control, reduced maintenance, and longer lifespan due to their brushless design.

Electronic Speed Controller (ESC)

Brushless motors require advanced Electronic Speed Controllers (ESCs) with electronic commutation for precise timing and efficiency, while brushed motors use simpler ESCs relying on mechanical brushes for commutation.

Armature Winding

Brushless motors eliminate the armature winding found in brushed motors by integrating permanent magnets on the rotor, enhancing efficiency and reducing maintenance.

Hall Effect Sensor

Brushless motors utilize Hall Effect sensors for precise rotor position detection, enabling efficient commutation and improved performance compared to brushed motors lacking such sensors.

Torque Ripple

Brushless motors exhibit significantly lower torque ripple compared to brushed motors, resulting in smoother operation and enhanced performance in precision applications.

Back Electromotive Force (Back-EMF)

Brushless motors generate more consistent and higher Back Electromotive Force (Back-EMF) due to their electronic commutation, resulting in improved efficiency and lower maintenance compared to brushed motors, which experience variable Back-EMF caused by mechanical brush contact.

Coreless Motor

Coreless motors, a type of brushless motor, offer higher efficiency, reduced electromagnetic interference, and superior speed control compared to traditional brushed motors, making them ideal for precision applications.

Stator-Laminations

Brushless motors utilize stacked stator laminations with precise insulation to reduce eddy current losses and enhance magnetic efficiency compared to the solid or less optimized stator laminations in brushed motors.

Pulse Width Modulation (PWM)

Brushless motors utilize Pulse Width Modulation (PWM) for precise speed control and higher efficiency compared to brushed motors, which rely on PWM primarily for speed regulation but suffer from mechanical wear due to brushes.

brushed motors vs brushless motors Infographic

njnir.com

njnir.com