Bolts and screws both serve as fasteners but differ primarily in their design and application; bolts typically require a nut to secure components, whereas screws are designed to thread directly into materials. Bolts offer higher strength and are favored in heavy-duty mechanical assemblies, while screws provide more efficient assembly in lightweight or precision applications. Selecting the appropriate fastener depends on load requirements, material compatibility, and disassembly needs in mechanical engineering projects.

Table of Comparison

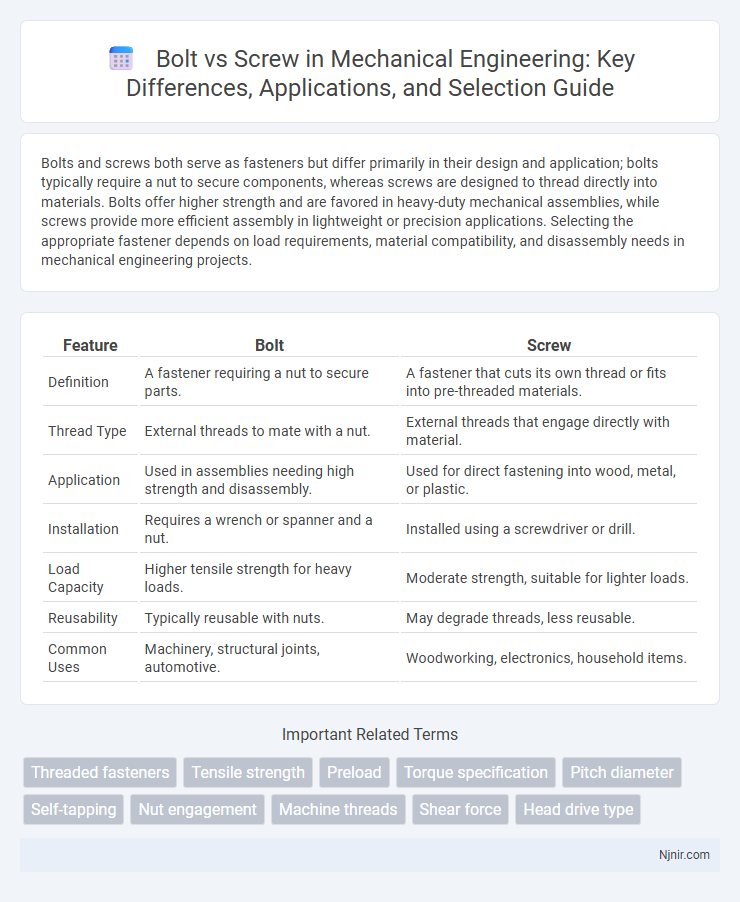

| Feature | Bolt | Screw |

|---|---|---|

| Definition | A fastener requiring a nut to secure parts. | A fastener that cuts its own thread or fits into pre-threaded materials. |

| Thread Type | External threads to mate with a nut. | External threads that engage directly with material. |

| Application | Used in assemblies needing high strength and disassembly. | Used for direct fastening into wood, metal, or plastic. |

| Installation | Requires a wrench or spanner and a nut. | Installed using a screwdriver or drill. |

| Load Capacity | Higher tensile strength for heavy loads. | Moderate strength, suitable for lighter loads. |

| Reusability | Typically reusable with nuts. | May degrade threads, less reusable. |

| Common Uses | Machinery, structural joints, automotive. | Woodworking, electronics, household items. |

Introduction to Bolts and Screws

Bolts and screws are essential fasteners used to join materials, but they differ in design and application. Bolts typically require a nut to secure components, featuring a uniform thread and smooth shank for high-strength clamping. Screws have a tapered, threaded shaft that anchors directly into materials, providing stability through friction and thread engagement.

Defining Bolts: Key Characteristics

Bolts are fasteners characterized by a cylindrical body with external threads designed to fit into a corresponding internally threaded nut or tapped hole, providing strong clamping force. Unlike screws, bolts typically require a nut to secure materials and are often larger with a uniform diameter along the shank. Common materials for bolts include steel, stainless steel, and alloy, optimized for high tensile strength and durability in construction, machinery, and automotive applications.

Defining Screws: Essential Features

Screws are characterized by their helical ridges or threads designed to convert rotational force into linear motion, enabling secure fastening in various materials. Unlike bolts, screws typically form their own mating threads in the material, offering self-tapping capabilities for enhanced grip. Essential features include a tapered shaft, a pointed tip for material penetration, and a variety of head designs to accommodate diverse driving tools.

Comparative Anatomy: Bolt vs Screw

Bolts feature a uniform diameter and are designed to be used with nuts, providing strong clamping force through external threading along their shaft. Screws typically have a tapered shaft with integrated threading that allows them to tap directly into materials, creating their own internal thread. The head shapes differ significantly, with bolts often having hexagonal heads for wrench application, while screws come with varied head types suited for screwdrivers, reflecting their distinct functional uses.

Installation Techniques: Bolts vs Screws

Bolt installation requires pre-drilling a clearance hole and often using a nut to secure the fastener, providing high-strength connections ideal for heavy-duty applications. Screws install by directly threading into materials without a nut, utilizing their tapered threads to create a strong grip, making them suitable for lighter-duty or wood-based projects. Torque control is critical for bolts to ensure proper clamping force, while screws rely on appropriate pilot hole size and driving technique to prevent material damage and ensure holding power.

Mechanical Strength and Load Capabilities

Bolts typically offer higher mechanical strength and load-bearing capacity compared to screws due to their larger diameter and ability to be tensioned with nuts, distributing stress evenly across joints. Screws are generally suited for lighter applications where precise holding power is required in materials such as wood or plastic, but they may fail under heavy shear or tensile loads. Choosing between a bolt and a screw depends on the specific load requirements, with bolts preferred for structural and heavy-duty assemblies.

Applications in Mechanical Assemblies

Bolts provide high clamping force and are ideal for heavy-duty mechanical assemblies requiring detachable joints, such as engine blocks and machinery frames. Screws are preferred for lighter loads and precision fastening in components like electronic enclosures and small appliances. Both fasteners enable secure assembly but differ in load capacity and ease of removal depending on application requirements.

Material and Thread Differences

Bolts typically use high-strength steel or stainless steel materials for enhanced durability and load-bearing capacity, while screws may be made from softer metals or plastics depending on their application. Bolt threads are usually coarse and uniform, designed for use with nuts and pre-tapped holes to provide strong clamping force; screws possess finer or specialized threads that often cut into the material itself for secure fastening without the need for nuts. The differences in material choice and thread design impact their suitability for structural versus lighter, precision fastening tasks.

Cost and Availability Considerations

Bolts generally cost more than screws due to their larger size and the higher strength materials used in manufacturing, but they offer superior durability for heavy-duty applications. Screws are widely available in various sizes and materials, making them more budget-friendly and accessible for everyday projects. The cost-efficiency of screws often makes them the preferred choice for light to medium load fastening needs, while bolts are typically reserved for structural tasks requiring maximum strength.

Choosing Between Bolts and Screws in Engineering Design

Selecting between bolts and screws in engineering design depends on load requirements, material compatibility, and assembly conditions. Bolts typically provide superior shear and tensile strength for heavy-duty applications with nuts and washers, while screws offer ease of installation in pre-threaded or softer materials. Evaluating joint disassembly needs and vibration exposure guides optimal fastener choice to ensure structural integrity and maintenance efficiency.

Threaded fasteners

Threaded fasteners like bolts provide strong clamping force with a nut, while screws rely on their tapered threads to grip materials directly without a nut.

Tensile strength

Bolts generally exhibit higher tensile strength than screws due to their thicker diameter and uniform thread design, making them more suitable for heavy-load applications.

Preload

Bolts achieve higher preload than screws due to their larger diameter and thread design, enabling greater clamping force and joint stability.

Torque specification

Bolt torque specifications vary based on diameter and material, requiring precise calibration to prevent joint failure, while screw torque is generally lower and depends on thread type and substrate hardness.

Pitch diameter

Pitch diameter is the critical measurement determining the fit and strength of bolts and screws, influencing thread engagement and load distribution.

Self-tapping

Self-tapping screws create their own internal threads in materials, providing faster and more efficient fastening compared to bolts, which require pre-threaded holes or nuts.

Nut engagement

Nut engagement is critical for bolts as it ensures proper thread alignment and load distribution, unlike screws which typically rely on tapping into materials without a separate nut.

Machine threads

Machine threads in bolts offer precise, uniform engagement for high-strength fastening compared to screws, which often have varied thread profiles designed for different materials and applications.

Shear force

Bolts typically resist higher shear forces than screws due to their larger diameter and stronger material composition.

Head drive type

Bolt head drive types commonly include hex, socket, and flange designs, while screws often feature Phillips, slotted, or Torx drives optimized for torque and application precision.

bolt vs screw Infographic

njnir.com

njnir.com