Shape memory alloys (SMAs) exhibit large strain recovery through phase transformation triggered by temperature changes, making them ideal for applications requiring flexible, compact actuators. Piezoelectric actuators convert electrical energy directly into precise mechanical displacement with high response speed and accuracy, suitable for microscale and high-frequency operations. While SMAs offer significant actuation strain, piezoelectric actuators provide superior control and repeatability in mechanical engineering applications.

Table of Comparison

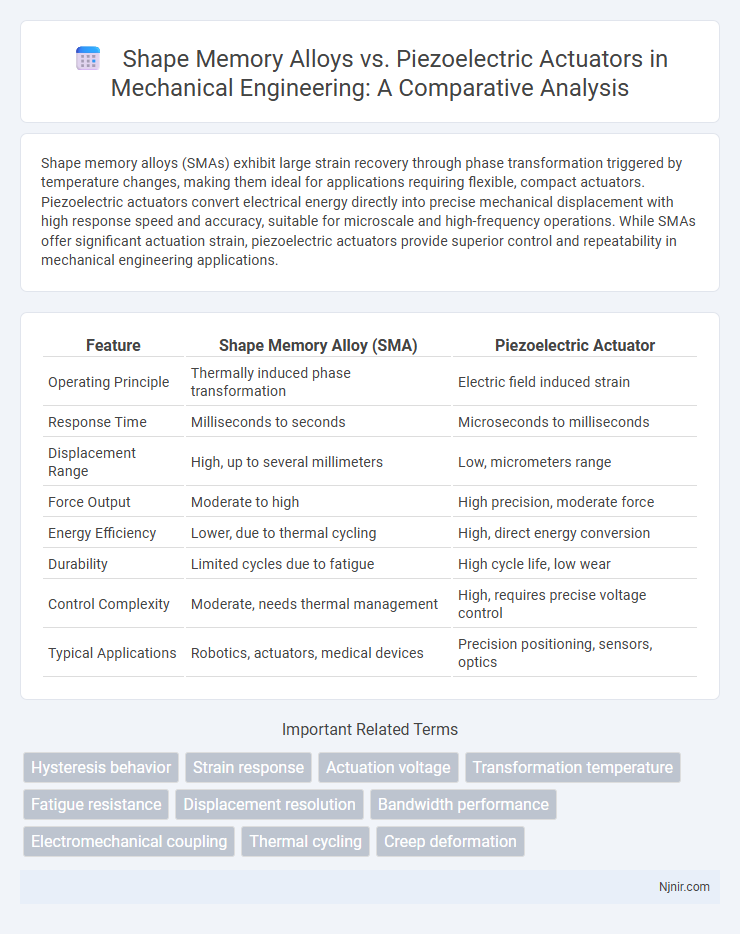

| Feature | Shape Memory Alloy (SMA) | Piezoelectric Actuator |

|---|---|---|

| Operating Principle | Thermally induced phase transformation | Electric field induced strain |

| Response Time | Milliseconds to seconds | Microseconds to milliseconds |

| Displacement Range | High, up to several millimeters | Low, micrometers range |

| Force Output | Moderate to high | High precision, moderate force |

| Energy Efficiency | Lower, due to thermal cycling | High, direct energy conversion |

| Durability | Limited cycles due to fatigue | High cycle life, low wear |

| Control Complexity | Moderate, needs thermal management | High, requires precise voltage control |

| Typical Applications | Robotics, actuators, medical devices | Precision positioning, sensors, optics |

Introduction to Shape Memory Alloys and Piezoelectric Actuators

Shape memory alloys (SMAs) are metallic materials that can recover their original shape after deformation when exposed to specific temperature changes, exhibiting properties like superelasticity and shape memory effect. Piezoelectric actuators rely on the piezoelectric effect, where certain materials generate mechanical displacement or force in response to an applied electric field, enabling precise motion control at micro and nano scales. Both SMAs and piezoelectric actuators are widely used in applications requiring actuation, but they differ fundamentally in their mechanisms, with SMAs driven by thermal activation and piezoelectric actuators by electrical signals.

Fundamental Working Principles

Shape memory alloys (SMAs) operate based on a thermally induced phase transformation between martensite and austenite phases, enabling them to recover predefined shapes when heated. Piezoelectric actuators function through the piezoelectric effect, where applied electric fields cause precise mechanical deformation in piezoelectric materials. SMAs rely on temperature-driven strain recovery, whereas piezoelectric actuators convert electrical energy directly into mechanical displacement.

Material Composition and Properties

Shape memory alloys (SMAs) are primarily composed of nickel-titanium (NiTi) or copper-based alloys, exhibiting unique properties such as superelasticity and the ability to return to a pre-defined shape upon heating due to a solid-state phase transformation. Piezoelectric actuators are made from ceramic materials like lead zirconate titanate (PZT) or quartz, characterized by their ability to generate mechanical strain when an electric field is applied, offering precise displacement at high frequencies. The key distinction lies in SMAs' thermally driven actuation with large strains and slower response times versus piezoelectric actuators' electrically driven, rapid, and small-strain actuation suitable for high-precision applications.

Actuation Mechanisms and Response Time

Shape memory alloys (SMAs) actuate through a solid-state phase transformation between martensite and austenite phases, producing large strains but typically exhibit slower response times ranging from milliseconds to seconds due to thermal activation requirements. Piezoelectric actuators rely on the inverse piezoelectric effect, where an applied electric field induces rapid mechanical deformation with response times in the microseconds to milliseconds range, enabling high-frequency operation. While SMAs provide substantial displacement and force, piezoelectric actuators offer superior precision and faster dynamic response suitable for applications demanding high-speed actuation.

Force and Displacement Capabilities

Shape memory alloys (SMAs) deliver high force output through phase transformation, often producing stresses up to 200 MPa, but typically offer limited displacement ranges around 5-8% strain. Piezoelectric actuators generate precise displacements on the micron to submicron scale with rapid response times, but their force capacity is generally lower, typically in the range of a few newtons to tens of newtons. Applications requiring large forces and moderate displacement benefit from SMAs, while scenarios needing high-resolution positioning with small force demand piezoelectric actuators.

Energy Efficiency and Power Requirements

Shape memory alloys (SMAs) typically exhibit lower energy efficiency due to the heat-driven phase transformation process requiring significant thermal energy and slow response times. Piezoelectric actuators demonstrate higher energy efficiency by directly converting electrical energy into mechanical displacement with minimal energy loss and rapid response. Power requirements for SMAs are generally higher and less precise, while piezoelectric actuators operate at lower voltages and offer better control for energy-sensitive applications.

Durability and Operational Lifespan

Shape memory alloys (SMAs) exhibit high durability with the ability to endure millions of cyclic transformations without significant degradation, making them suitable for applications requiring repeated shape recovery. Piezoelectric actuators typically offer a longer operational lifespan due to their solid-state mechanism and resistance to mechanical fatigue, often exceeding tens of millions of cycles. While SMAs can suffer from functional fatigue and reduced strain at elevated temperatures, piezoelectric actuators maintain consistent performance over a broad range of environmental conditions, highlighting their advantage in long-term reliability.

Applications in Mechanical Engineering

Shape memory alloys (SMAs) are extensively used in mechanical engineering for applications requiring actuation with large strains and recovering shape changes, such as adaptive structures, vibration control devices, and aerospace components. Piezoelectric actuators excel in precision positioning, high-frequency operations, and micro-scale adjustments, commonly found in robotics, ultrasonic transducers, and fine mechanical controls. Mechanical systems often integrate SMAs for deformation-driven actuation and piezoelectric actuators for rapid, high-accuracy movements, optimizing performance across diverse engineering applications.

Advantages and Limitations Comparison

Shape memory alloy actuators offer high force-to-weight ratios and large strain capabilities, making them ideal for applications requiring compact and lightweight actuation. Their limitations include slow response times and sensitivity to temperature variations, which can affect precision and reliability. Piezoelectric actuators provide rapid response speeds and high positioning accuracy but typically have limited displacement ranges and require high voltage inputs, constraining their use in high-strain applications.

Future Trends and Research Directions

Future trends in Shape Memory Alloy (SMA) actuators emphasize enhanced fatigue life, faster response times, and improved energy efficiency through nanostructured materials and hybrid composites. Research on Piezoelectric actuators focuses on developing lead-free materials, increasing displacement range via multilayer configurations, and integrating with smart sensors for real-time feedback control. Both actuator types benefit from advances in artificial intelligence-driven adaptive control and miniaturization for applications in soft robotics, aerospace, and biomedical devices.

Hysteresis behavior

Shape memory alloys exhibit significant hysteresis due to phase transformations causing nonlinear strain responses, whereas piezoelectric actuators demonstrate minimal hysteresis with more linear and repeatable displacement under electric fields.

Strain response

Shape memory alloys exhibit large recoverable strains up to 8% through phase transformation, while piezoelectric actuators provide smaller strains typically below 0.1% but offer faster response times and higher precision.

Actuation voltage

Shape memory alloys typically require high actuation voltages ranging from 2 to 5 volts per cycle, whereas piezoelectric actuators operate efficiently at lower voltages typically between 10 to 100 volts.

Transformation temperature

Shape memory alloys operate based on a specific transformation temperature that triggers the phase change between martensite and austenite, whereas piezoelectric actuators function through electrical voltage-induced strain without relying on temperature-dependent phase transformations.

Fatigue resistance

Shape memory alloys exhibit superior fatigue resistance compared to piezoelectric actuators, enabling longer operational lifespan in cyclic deformation applications.

Displacement resolution

Shape memory alloys typically offer lower displacement resolution ranging from micrometers to millimeters, while piezoelectric actuators provide high displacement resolution in the nanometer to micrometer range, enabling precise control in micro- and nano-scale applications.

Bandwidth performance

Shape memory alloy actuators exhibit lower bandwidth performance, typically in the range of a few Hz due to their thermal-based activation, whereas piezoelectric actuators achieve high bandwidths up to several kHz, making them suitable for rapid response applications.

Electromechanical coupling

Shape memory alloys exhibit moderate electromechanical coupling through thermally induced phase transformations, while piezoelectric actuators provide high electromechanical coupling efficiency by directly converting electrical energy into mechanical strain.

Thermal cycling

Shape memory alloy actuators exhibit reduced performance and potential fatigue under repeated thermal cycling, whereas piezoelectric actuators maintain consistent precision and durability with minimal sensitivity to temperature fluctuations.

Creep deformation

Shape memory alloys exhibit significant creep deformation under prolonged stress and elevated temperatures, whereas piezoelectric actuators demonstrate minimal creep but can suffer from hysteresis and polarization degradation over time.

Shape memory alloy vs Piezoelectric actuator Infographic

njnir.com

njnir.com