Shape memory alloys (SMAs) exhibit exceptional mechanical strength and recovery stress, enabling precise deformation and return to original shape under thermal stimuli, making them ideal for load-bearing applications. Smart polymers offer greater flexibility and biocompatibility, responding to various environmental triggers like temperature, pH, or light, which is advantageous for biomedical devices and adaptive surfaces. Combining SMAs with smart polymers can optimize performance by leveraging the high actuation force of alloys and the tunable responsiveness of polymers in advanced mechanical engineering systems.

Table of Comparison

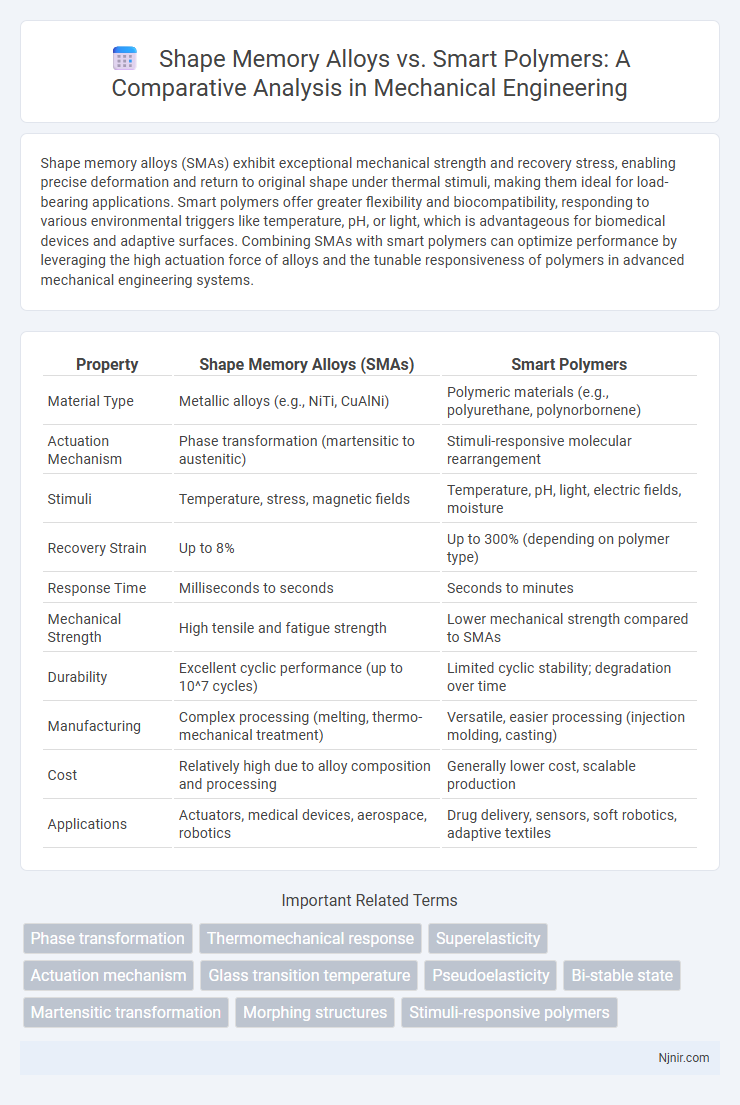

| Property | Shape Memory Alloys (SMAs) | Smart Polymers |

|---|---|---|

| Material Type | Metallic alloys (e.g., NiTi, CuAlNi) | Polymeric materials (e.g., polyurethane, polynorbornene) |

| Actuation Mechanism | Phase transformation (martensitic to austenitic) | Stimuli-responsive molecular rearrangement |

| Stimuli | Temperature, stress, magnetic fields | Temperature, pH, light, electric fields, moisture |

| Recovery Strain | Up to 8% | Up to 300% (depending on polymer type) |

| Response Time | Milliseconds to seconds | Seconds to minutes |

| Mechanical Strength | High tensile and fatigue strength | Lower mechanical strength compared to SMAs |

| Durability | Excellent cyclic performance (up to 10^7 cycles) | Limited cyclic stability; degradation over time |

| Manufacturing | Complex processing (melting, thermo-mechanical treatment) | Versatile, easier processing (injection molding, casting) |

| Cost | Relatively high due to alloy composition and processing | Generally lower cost, scalable production |

| Applications | Actuators, medical devices, aerospace, robotics | Drug delivery, sensors, soft robotics, adaptive textiles |

Introduction to Shape Memory Alloys and Smart Polymers

Shape memory alloys (SMAs) are metal alloys that return to a predetermined shape when exposed to specific thermal conditions due to a reversible phase transformation. Smart polymers are responsive materials that undergo significant changes in shape, size, or properties in reaction to stimuli such as temperature, pH, or light. Both SMAs and smart polymers serve crucial roles in actuators, sensors, and adaptive systems due to their unique ability to respond dynamically to environmental changes.

Fundamental Mechanisms: How They Work

Shape memory alloys (SMAs) function through phase transformations between martensite and austenite structures, enabling them to recover predefined shapes upon heating. Smart polymers rely on changes in their molecular chain configuration, triggered by stimuli such as temperature, pH, or light, causing reversible deformation or shape change. The fundamental mechanism in SMAs is a solid-state phase transition, while in smart polymers, it is a conformational change in polymer chains responding to environmental cues.

Material Properties Comparison

Shape memory alloys exhibit exceptional mechanical strength, high fatigue resistance, and the ability to undergo reversible phase transformations, enabling precise shape recovery under temperature changes. Smart polymers, characterized by their lightweight nature and excellent biocompatibility, respond to various stimuli such as temperature, pH, and light with significant elasticity and tunable stiffness. Material properties comparison highlights that shape memory alloys offer superior durability and force output, while smart polymers provide greater flexibility and adaptability for diverse biomedical and soft robotics applications.

Actuation Performance and Response Time

Shape memory alloys (SMAs) exhibit high actuation force and large recovery stress, making them ideal for applications requiring strong mechanical work output, whereas smart polymers deliver lower force but offer greater deformation and flexibility. SMAs typically have slower response times ranging from milliseconds to seconds due to phase transformation processes, while smart polymers respond faster, often within milliseconds, owing to their molecular reconfiguration mechanisms. Actuation performance in SMAs is driven by thermomechanical transitions, whereas smart polymers rely on stimuli such as temperature, pH, or light for rapid and reversible shape changes.

Temperature and Environmental Sensitivity

Shape memory alloys (SMAs) exhibit precise temperature-dependent phase transformations, enabling predictable shape recovery typically between 20degC and 100degC, making them highly sensitive to thermal changes. Smart polymers demonstrate a broader environmental responsiveness, reacting to stimuli such as temperature, pH, and humidity, with transition temperatures often tailored within 30degC to 50degC for biomedical applications. The temperature sensitivity of SMAs is generally sharper and more mechanically robust, while smart polymers offer greater versatility under varying environmental conditions.

Design Flexibility and Form Factor

Shape memory alloys (SMAs) offer limited design flexibility due to their fixed crystalline structures but provide high strength and precise actuation within compact form factors. Smart polymers, in contrast, exhibit greater design versatility with tunable mechanical properties and diverse morphologies, allowing for complex shapes and lightweight configurations. These differences make SMAs ideal for applications requiring robust, repeatable movements, while smart polymers excel in customizable, adaptable designs where form factor complexity is critical.

Applications in Mechanical Engineering

Shape memory alloys (SMAs) are widely used in mechanical engineering for actuators, vibration damping, and adaptive structures due to their high strength and temperature-triggered phase transformations. Smart polymers offer advantages in lightweight, flexible designs for sensors, self-healing materials, and soft robotics, driven by their responsiveness to stimuli like temperature, pH, or light. The integration of SMAs and smart polymers enables the development of multifunctional devices combining rigidity and flexibility for advanced mechanical systems.

Durability and Fatigue Resistance

Shape memory alloys (SMAs) exhibit superior durability and fatigue resistance due to their metallic crystalline structure, allowing them to withstand millions of deformation cycles without significant degradation. In contrast, smart polymers generally have lower fatigue resistance and durability, as their polymeric chains are more susceptible to mechanical wear and environmental factors such as UV exposure and moisture. SMAs are preferred in high-stress applications requiring long-term reliability, while smart polymers are better suited for flexible, low-load conditions.

Cost and Manufacturing Considerations

Shape memory alloys (SMAs) generally have higher raw material and processing costs due to complex alloy compositions and precise thermal treatments required during manufacturing. Smart polymers offer more cost-effective production with simpler synthesis methods and easier scalability, making them suitable for large-volume applications. Manufacturing SMAs involves energy-intensive processes and post-processing steps, whereas smart polymers benefit from lower temperature curing and printing techniques, reducing overall fabrication expenses.

Future Trends and Innovation

Shape memory alloys (SMAs) are evolving with enhanced fatigue resistance and multifunctional capabilities, integrating with sensors for advanced biomedical and aerospace applications. Smart polymers are advancing through increased biocompatibility and stimuli-responsive behaviors, targeting drug delivery, soft robotics, and flexible electronics. Future trends emphasize hybrid materials combining SMAs' mechanical strength with smart polymers' adaptability to create next-generation actuators and adaptive systems.

Phase transformation

Shape memory alloys exhibit reversible phase transformations between martensite and austenite phases enabling shape recovery, while smart polymers rely on molecular conformational changes without distinct phase transitions for their responsive behavior.

Thermomechanical response

Shape memory alloys exhibit rapid and highly durable thermomechanical responses through phase transformation, while smart polymers demonstrate slower, more flexible, and tunable responses via molecular reconfiguration.

Superelasticity

Shape memory alloys exhibit superior superelasticity with high recoverable strains up to 8%, while smart polymers typically provide lower superelastic performance but offer greater flexibility and biocompatibility.

Actuation mechanism

Shape memory alloys actuate through temperature-induced phase transformations causing shape change, while smart polymers actuate via stimuli-responsive molecular rearrangements triggered by heat, light, or pH.

Glass transition temperature

Shape memory alloys exhibit phase transformations at specific temperatures while smart polymers undergo a glass transition near their tunable glass transition temperature (Tg), directly influencing their actuation and mechanical properties.

Pseudoelasticity

Shape memory alloys exhibit superior pseudoelasticity compared to smart polymers, enabling reversible deformation under stress without permanent shape changes.

Bi-stable state

Shape memory alloys exhibit distinct bi-stable states with sharp phase transformations enabling rapid and reversible shape changes, whereas smart polymers display more gradual, tunable bi-stability through molecular rearrangements responsive to environmental stimuli.

Martensitic transformation

Shape memory alloys exhibit Martensitic transformation enabling reversible phase changes for shape recovery, whereas smart polymers rely on molecular rearrangements without a crystalline phase transition.

Morphing structures

Shape memory alloys offer high strength and rapid actuation for morphing structures, while smart polymers provide greater flexibility and lightweight adaptability, making each material suitable for different morphing applications.

Stimuli-responsive polymers

Shape memory alloys exhibit thermally induced phase transformations for shape restoration, while stimuli-responsive polymers, including smart polymers, achieve reversible changes in properties through external stimuli such as temperature, pH, or light, offering versatile applications in biomedical and adaptive materials.

Shape memory alloys vs smart polymers Infographic

njnir.com

njnir.com