Pneumatic systems utilize compressed air to transmit energy, offering faster motion and cleaner operation, while hydraulic systems rely on incompressible fluids for higher force and precise control. Pneumatics excel in applications requiring speed and lightweight components, whereas hydraulics are preferred for heavy-duty tasks demanding substantial power and durability. Both systems play crucial roles in mechanical engineering, with selection depending on factors like load capacity, speed, and environmental conditions.

Table of Comparison

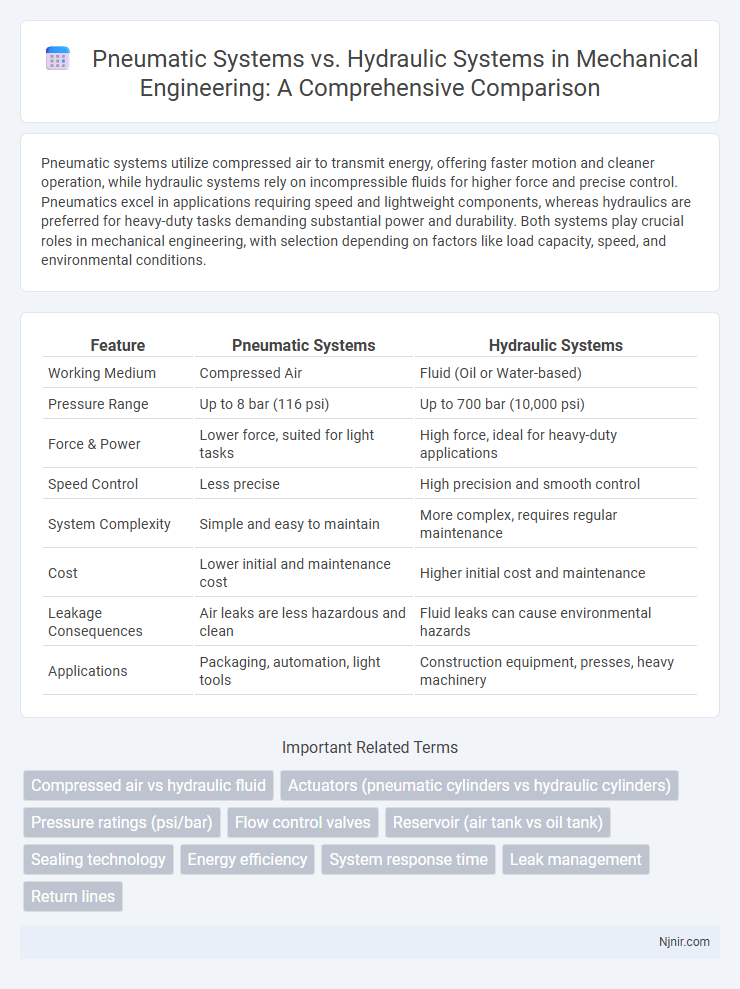

| Feature | Pneumatic Systems | Hydraulic Systems |

|---|---|---|

| Working Medium | Compressed Air | Fluid (Oil or Water-based) |

| Pressure Range | Up to 8 bar (116 psi) | Up to 700 bar (10,000 psi) |

| Force & Power | Lower force, suited for light tasks | High force, ideal for heavy-duty applications |

| Speed Control | Less precise | High precision and smooth control |

| System Complexity | Simple and easy to maintain | More complex, requires regular maintenance |

| Cost | Lower initial and maintenance cost | Higher initial cost and maintenance |

| Leakage Consequences | Air leaks are less hazardous and clean | Fluid leaks can cause environmental hazards |

| Applications | Packaging, automation, light tools | Construction equipment, presses, heavy machinery |

Introduction to Pneumatic and Hydraulic Systems

Pneumatic systems use compressed air to transmit and control energy, offering lightweight components and fast response times ideal for automation and manufacturing processes. Hydraulic systems rely on incompressible fluids under pressure to deliver high force and precise control, making them suitable for heavy machinery and applications requiring substantial power. Both systems convert energy into mechanical motion but differ in their working mediums, pressure ranges, and typical use cases.

Fundamental Principles of Operation

Pneumatic systems operate by compressing air or gas to transmit energy, relying on the principles of fluid dynamics and Boyle's Law for pressure and volume control. Hydraulic systems use incompressible fluids, typically oil, to generate force and motion through Pascal's Principle, which states that pressure applied to a confined fluid is transmitted equally in all directions. The fundamental distinction lies in pneumatic systems utilizing compressible gases for high-speed, low-force applications, while hydraulic systems exploit incompressible liquids for precise, high-force control and power density.

Key Components Comparison

Pneumatic systems primarily use compressed air as the working fluid, relying on components such as compressors, air tanks, valves, and pneumatic cylinders to generate motion. Hydraulic systems utilize incompressible fluids like oil, featuring key components including hydraulic pumps, reservoirs, valves, and hydraulic actuators for precise control. The main differences in components influence system performance, with pneumatics offering faster response and lower force, while hydraulics provide higher force and more accurate control.

Energy Sources and Transmission

Pneumatic systems utilize compressed air as their energy source, providing fast, clean, and lightweight transmission ideal for applications requiring high speed and moderate force. Hydraulic systems rely on incompressible fluid, typically oil, to transmit energy, delivering greater power density and precise control suitable for heavy-duty machinery and high-force requirements. The energy transmission in pneumatics occurs through air compression and expansion, while hydraulics transfer energy via fluid pressure in closed circuits, resulting in different efficiency and maintenance profiles.

Efficiency and Power Output

Pneumatic systems offer faster response times and are ideal for lightweight applications but generally exhibit lower efficiency due to air compressibility and energy losses. Hydraulic systems deliver significantly higher power output and superior force control, making them more efficient for heavy-duty operations requiring precise and consistent performance. The choice between pneumatic and hydraulic systems largely depends on the application's power demands and efficiency requirements, with hydraulics favored for maximum power and pneumatics for speed and cost-effectiveness.

Applications in Mechanical Engineering

Pneumatic systems are widely used in mechanical engineering for applications requiring fast movement and low force, such as automation in assembly lines, packaging equipment, and material handling. Hydraulic systems provide high force and precise control, making them ideal for heavy machinery like construction equipment, presses, and lifting devices. Both systems are selected based on load requirements, speed, and environmental factors to optimize performance and efficiency.

Maintenance and Safety Considerations

Pneumatic systems require less maintenance due to simpler components and the use of clean, dry air, reducing the risk of contamination and corrosion, whereas hydraulic systems demand rigorous maintenance to manage fluid leaks, contamination, and seal integrity. Safety considerations for pneumatic systems include potential risks from high-pressure air bursts and noise hazards, while hydraulic systems pose greater dangers from high-pressure fluid leaks, fire hazards from flammable hydraulic fluids, and environmental contamination. Proper maintenance schedules, leak detection protocols, and use of compatible materials are critical for both systems to ensure operational safety and longevity.

Cost Analysis and Economic Factors

Pneumatic systems generally have lower initial costs and maintenance expenses due to simpler components and cleaner operation compared to hydraulic systems, which require more expensive pumps, fluids, and sealing elements. Operating costs for pneumatic systems increase with energy inefficiencies, as compressed air generation demands significant power, whereas hydraulic systems tend to be more energy-efficient in heavy-duty applications despite higher fluid maintenance costs. Long-term economic factors favor pneumatic systems in environments prioritizing cleanliness and low maintenance, while hydraulic systems offer cost advantages in high-force, precision-demanding industries where durability and power density are critical.

Environmental Impact and Sustainability

Pneumatic systems utilize compressed air, which is abundant and non-toxic, resulting in lower environmental impact compared to hydraulic systems that rely on petroleum-based fluids prone to leaks and soil contamination. The energy efficiency of pneumatic systems varies, but modern designs aim to reduce air consumption and minimize greenhouse gas emissions associated with electricity production. Hydraulic systems offer higher power density and precision but often require stringent fluid management and disposal protocols to ensure sustainability and reduce ecological harm.

Future Trends in Fluid Power Systems

The future of fluid power systems is marked by increased integration of smart technologies and energy-efficient designs, with pneumatic systems evolving through advanced air compression methods and integration with digital control for rapid, lightweight applications. Hydraulic systems are expected to advance with improved fluid formulations and electro-hydraulic hybrids that enhance precision and power density for heavy-duty industrial uses. Both systems are leveraging IoT and AI for predictive maintenance and real-time optimization, driving innovation in automation and sustainable energy consumption.

Compressed air vs hydraulic fluid

Compressed air in pneumatic systems offers faster response times and cleaner operation compared to hydraulic fluid in hydraulic systems, which provides higher force and precise control for heavy-duty applications.

Actuators (pneumatic cylinders vs hydraulic cylinders)

Pneumatic cylinders offer faster, cleaner, and more cost-effective actuation for light to medium loads, while hydraulic cylinders provide higher force, precise control, and durability for heavy-duty industrial applications.

Pressure ratings (psi/bar)

Pneumatic systems typically operate at lower pressure ratings around 80-120 psi (5.5-8.3 bar), while hydraulic systems handle significantly higher pressures, often ranging from 1,000 to 5,000 psi (70-350 bar).

Flow control valves

Flow control valves in pneumatic systems regulate air pressure and flow for precise actuator speed control, while hydraulic systems use these valves to manage high-pressure incompressible fluid flow for powerful, smooth operation.

Reservoir (air tank vs oil tank)

Pneumatic systems use air tanks as reservoirs for compressed air, offering lighter weight and faster response, while hydraulic systems rely on oil tanks that provide higher pressure capacity and better fluid lubrication for heavy-duty applications.

Sealing technology

Pneumatic systems use compressible air requiring basic sealing solutions, whereas hydraulic systems rely on incompressible fluids demanding advanced sealing technology to prevent leaks and maintain high pressure.

Energy efficiency

Hydraulic systems deliver higher energy efficiency than pneumatic systems due to their superior power density and minimal compressibility losses.

System response time

Pneumatic systems typically offer faster response times than hydraulic systems due to the lower density and compressibility of air compared to hydraulic fluid.

Leak management

Pneumatic systems typically experience less severe leak consequences due to compressible air use, whereas hydraulic systems demand rigorous leak management because fluid leaks can cause significant environmental harm and operational failures.

Return lines

Return lines in pneumatic systems typically expel compressed air back into the atmosphere, while hydraulic system return lines circulate pressurized fluid back to the reservoir for reuse in the system.

Pneumatic systems vs hydraulic systems Infographic

njnir.com

njnir.com