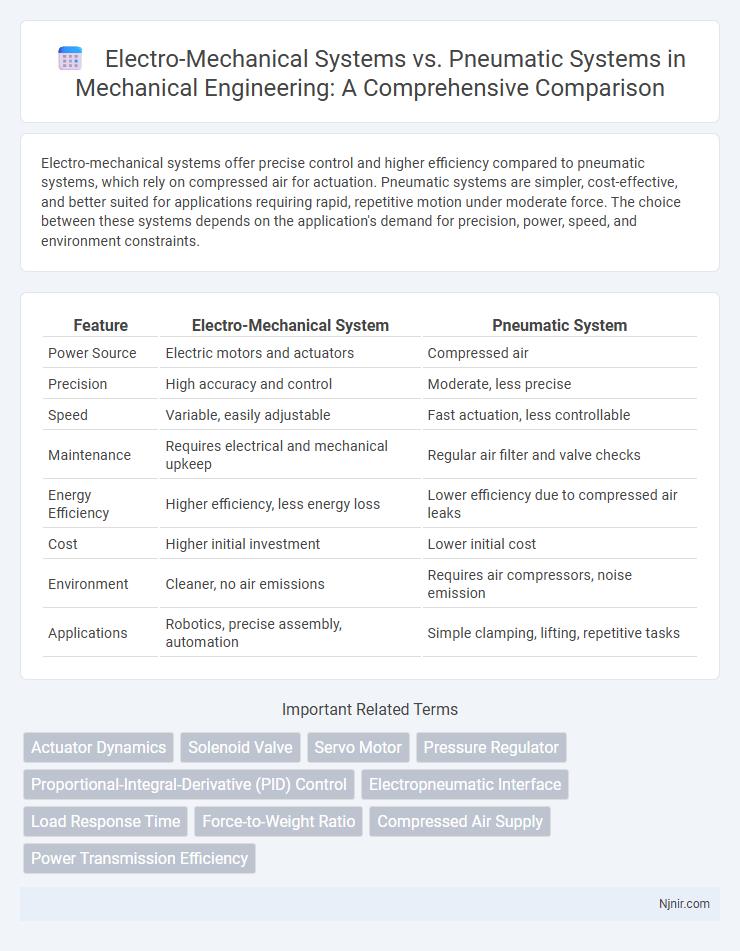

Electro-mechanical systems offer precise control and higher efficiency compared to pneumatic systems, which rely on compressed air for actuation. Pneumatic systems are simpler, cost-effective, and better suited for applications requiring rapid, repetitive motion under moderate force. The choice between these systems depends on the application's demand for precision, power, speed, and environment constraints.

Table of Comparison

| Feature | Electro-Mechanical System | Pneumatic System |

|---|---|---|

| Power Source | Electric motors and actuators | Compressed air |

| Precision | High accuracy and control | Moderate, less precise |

| Speed | Variable, easily adjustable | Fast actuation, less controllable |

| Maintenance | Requires electrical and mechanical upkeep | Regular air filter and valve checks |

| Energy Efficiency | Higher efficiency, less energy loss | Lower efficiency due to compressed air leaks |

| Cost | Higher initial investment | Lower initial cost |

| Environment | Cleaner, no air emissions | Requires air compressors, noise emission |

| Applications | Robotics, precise assembly, automation | Simple clamping, lifting, repetitive tasks |

Introduction to Electro-Mechanical and Pneumatic Systems

Electro-mechanical systems integrate electrical components with mechanical processes to control machines and devices, utilizing motors, sensors, and actuators for precise movement and automation. Pneumatic systems operate using compressed air to power mechanical motion, offering simplicity, fast response times, and cost-effective solutions for applications requiring linear or rotary movement. Understanding the fundamental principles of these systems aids in selecting the appropriate technology for industrial automation, robotics, and manufacturing processes.

Fundamental Operating Principles

Electro-mechanical systems operate through the conversion of electrical energy into mechanical motion using motors, actuators, or solenoids controlled by electrical circuits or microprocessors. Pneumatic systems utilize compressed air to generate mechanical movement, relying on valves, cylinders, and air compressors to control force and motion. The fundamental difference lies in energy source and transmission; electro-mechanical systems depend on electrical input and precise control, while pneumatic systems leverage the pressure and flow of air for actuation.

Key Components and Configurations

Electro-mechanical systems rely on electric motors, actuators, sensors, and controllers to perform precise mechanical movements, emphasizing components like gears, shafts, and position encoders for accuracy. Pneumatic systems utilize compressors, valves, cylinders, and air treatment units, depending on compressed air to generate linear or rotary motion, with configurations often including directional control valves and air reservoirs. Understanding the distinct key components and configurations of these systems is essential for selecting the appropriate technology based on application requirements such as speed, force, and control precision.

Energy Sources and Consumption

Electro-mechanical systems utilize electrical energy to drive motors and actuators, offering precise control and high efficiency in energy consumption for varying loads. Pneumatic systems rely on compressed air as their energy source, which often results in higher energy losses due to air compression and leakage, making them less efficient for continuous operation. Energy consumption in electro-mechanical systems is typically lower and more controllable, while pneumatic systems demand energy-intensive compressors and experience pressure drops that increase overall power usage.

Control and Automation Capabilities

Electro-mechanical systems offer precise control and high repeatability through integrated sensors and programmable logic controllers (PLCs), enabling complex automation tasks with rapid response times. Pneumatic systems provide robust and cost-effective control for simple, repetitive motions, but lack the fine-tuning and flexibility found in electro-mechanical automation. Advanced electro-mechanical systems support seamless integration with industrial IoT and real-time data monitoring, enhancing adaptive control in automated processes beyond the scope of pneumatic solutions.

Performance and Efficiency Comparisons

Electro-mechanical systems offer precise control and high energy efficiency due to their ability to convert electrical energy directly into mechanical motion with minimal loss. Pneumatic systems, while robust and capable of delivering high force, often suffer from lower efficiency because of air compression losses and leakage, impacting overall performance. In applications demanding rapid response and fine positioning, electro-mechanical systems consistently outperform pneumatic counterparts by providing better accuracy and repeatability.

Maintenance and Reliability Considerations

Electro-mechanical systems typically require more precise maintenance due to their complex components such as motors, sensors, and wiring, which can be prone to wear and electrical faults. Pneumatic systems, relying on compressed air, generally have fewer moving parts and simpler mechanisms, leading to lower maintenance frequency but potential issues with air leaks and compressor efficiency. Reliability in electro-mechanical systems hinges on electrical integrity and mechanical alignment, while pneumatic systems depend heavily on air quality and pressure regulation for consistent performance.

Safety and Environmental Impacts

Electro-mechanical systems offer enhanced safety through precise control and reduced risk of leaks compared to pneumatic systems, which can pose hazards due to compressed air leaks and sudden pressure releases. Environmental impacts favor electro-mechanical systems as they typically consume less energy and generate lower emissions, whereas pneumatic systems require continuous air compression, leading to higher energy use and associated carbon footprints. Proper maintenance of electro-mechanical components further minimizes environmental risks, unlike pneumatic systems that may release lubricants or contaminants into the atmosphere.

Cost Analysis and Economic Factors

Electro-mechanical systems generally incur higher initial costs due to complex components and precise manufacturing requirements, but they tend to have lower operating expenses because of energy efficiency and reduced maintenance needs. Pneumatic systems often feature lower upfront costs and simpler installation, yet ongoing expenses may escalate from air compressor energy consumption and frequent part replacements. Economic decision-making should weigh total cost of ownership, factoring in installation, energy use, durability, and maintenance frequency over the system's lifecycle.

Application Suitability and Industry Use Cases

Electro-mechanical systems offer precise control and are ideal for applications requiring complex data inputs and automation, commonly used in robotics, aerospace, and automotive manufacturing. Pneumatic systems excel in environments demanding high speed, simplicity, and cost-effectiveness, making them prevalent in packaging, food processing, and material handling industries. Industry use cases highlight electro-mechanical systems for tasks like robotic arm articulation and CNC machines, whereas pneumatic systems dominate air-powered tools and conveyor systems.

Actuator Dynamics

Electro-mechanical actuators exhibit precise, adjustable motion control with moderate response times, while pneumatic actuators provide faster response and higher force output but with less positional accuracy and variable dynamics due to compressible air.

Solenoid Valve

Solenoid valves in electro-mechanical systems provide precise, rapid control with electrical actuation, while pneumatic systems rely on compressed air for faster response and simpler maintenance but less electrical integration.

Servo Motor

Servo motors in electro-mechanical systems offer precise position control and higher efficiency compared to pneumatic systems that rely on compressed air for movement.

Pressure Regulator

Electro-mechanical pressure regulators offer precise digital control and adaptability, while pneumatic pressure regulators provide reliable, maintenance-free operation with simpler mechanical design for consistent pressure management.

Proportional-Integral-Derivative (PID) Control

Electro-mechanical systems offer precise Proportional-Integral-Derivative (PID) control with high accuracy and responsiveness, whereas pneumatic systems typically face challenges in PID tuning due to air compressibility and nonlinearities leading to less precise control.

Electropneumatic Interface

The electropneumatic interface integrates electro-mechanical systems with pneumatic systems by converting electrical signals into precise pneumatic control actions for enhanced automation efficiency.

Load Response Time

Electro-mechanical systems typically offer faster load response times than pneumatic systems due to precise motor control and reduced compressibility delays.

Force-to-Weight Ratio

Electro-mechanical systems typically offer a higher force-to-weight ratio compared to pneumatic systems due to their efficient energy conversion and compact actuator design.

Compressed Air Supply

Electro-mechanical systems rely on electrical power and motors for operation, while pneumatic systems depend on a compressed air supply, requiring air compressors and storage tanks to maintain consistent pressure and flow.

Power Transmission Efficiency

Electro-mechanical systems typically achieve higher power transmission efficiency than pneumatic systems due to reduced energy losses in mechanical components and the absence of compressible fluid dynamics.

Electro-mechanical system vs Pneumatic system Infographic

njnir.com

njnir.com