Hot forging involves shaping metal above its recrystallization temperature, allowing for significant deformation with reduced force and improved ductility, resulting in components with enhanced grain structure and mechanical properties. Cold forging, performed at or near room temperature, increases strength through strain hardening and achieves tighter tolerances and better surface finish but requires higher force and may induce residual stresses. Selecting between hot and cold forging depends on the material, desired mechanical properties, and application requirements, balancing factors such as strength, precision, and cost-efficiency.

Table of Comparison

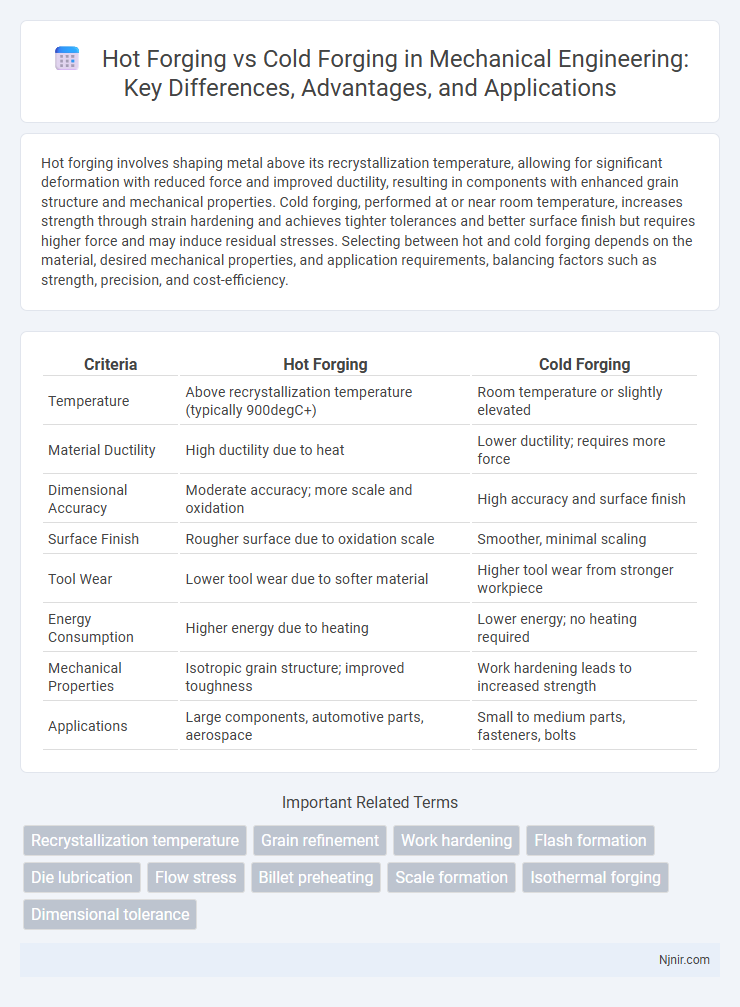

| Criteria | Hot Forging | Cold Forging |

|---|---|---|

| Temperature | Above recrystallization temperature (typically 900degC+) | Room temperature or slightly elevated |

| Material Ductility | High ductility due to heat | Lower ductility; requires more force |

| Dimensional Accuracy | Moderate accuracy; more scale and oxidation | High accuracy and surface finish |

| Surface Finish | Rougher surface due to oxidation scale | Smoother, minimal scaling |

| Tool Wear | Lower tool wear due to softer material | Higher tool wear from stronger workpiece |

| Energy Consumption | Higher energy due to heating | Lower energy; no heating required |

| Mechanical Properties | Isotropic grain structure; improved toughness | Work hardening leads to increased strength |

| Applications | Large components, automotive parts, aerospace | Small to medium parts, fasteners, bolts |

Introduction to Hot Forging and Cold Forging

Hot forging involves shaping metal at high temperatures above its recrystallization point, enhancing ductility and reducing forces needed for deformation. Cold forging is performed at or near room temperature, producing precise dimensions and superior surface finish due to strain hardening. Both methods optimize mechanical properties and manufacturing efficiency depending on the material and application requirements.

Fundamental Differences Between Hot and Cold Forging

Hot forging involves shaping metal at temperatures above its recrystallization point, allowing greater ductility and reduced strength, which enables complex geometries with less force. Cold forging occurs at or near room temperature, resulting in higher strength and improved surface finish due to strain hardening, but requires more force and limits the intricacy of shapes. The fundamental differences lie in temperature conditions, material behavior, and resulting mechanical properties, influencing the choice based on application requirements and desired metal characteristics.

Key Advantages of Hot Forging

Hot forging offers superior material ductility by heating metals above recrystallization temperatures, minimizing strain hardening and reducing the risk of cracks. This process enhances grain refinement, resulting in improved mechanical properties like increased strength and toughness. Moreover, hot forging allows for more complex shapes and larger workpieces to be formed efficiently compared to cold forging.

Core Benefits of Cold Forging

Cold forging enhances material strength and surface finish through work hardening without the need for additional heat, resulting in superior dimensional accuracy and reduced machining requirements. This process also minimizes oxidation and scaling, preserving material integrity while enabling cost-effective, high-volume production with consistent quality. Cold forging is particularly advantageous for manufacturing precision components in the automotive and aerospace industries where tight tolerances and durability are critical.

Material Suitability for Hot and Cold Forging

Hot forging is ideal for materials with high ductility and low strain hardening rates, such as carbon steel, alloy steel, and stainless steel, as the elevated temperatures reduce yield strength and improve formability. Cold forging is best suited for materials with good cold workability, including low-carbon steel, copper, aluminum, and brass, which exhibit excellent strength and surface finish after deformation at or near room temperature. Material selection depends on factors like thermal conductivity, work hardening behavior, and required mechanical properties for the intended application.

Applications in Automotive and Aerospace Industries

Hot forging is predominantly used in the automotive and aerospace industries for manufacturing high-strength components such as crankshafts, connecting rods, and turbine blades, where enhanced ductility and toughness at elevated temperatures are essential. Cold forging is preferred for producing smaller, intricate parts like fasteners, gears, and pins due to its superior surface finish, dimensional accuracy, and increased fatigue resistance without the need for additional heat treatment. Both processes are critical in optimizing part performance, weight reduction, and manufacturing efficiency in demanding automotive and aerospace applications.

Surface Finish and Dimensional Accuracy Comparison

Hot forging typically results in a rougher surface finish due to high temperatures causing scale formation and oxidation, while cold forging produces smoother surfaces with finer details because it occurs at or near room temperature. Dimensional accuracy is generally higher in cold forging, where material flow is more controlled and minimal thermal expansion occurs, enabling tighter tolerances. Hot forging often requires additional machining to achieve precise dimensions, whereas cold forging parts frequently meet final specifications directly from the die.

Mechanical Properties: Strength and Durability

Hot forging enhances mechanical properties by allowing metals to deform easily at elevated temperatures, resulting in refined grain structures that improve strength and durability. Cold forging, performed at room temperature, increases strength through work hardening and produces superior surface finish and dimensional accuracy. While hot forging offers better ductility and toughness, cold forging provides higher yield strength and fatigue resistance due to strain hardening effects.

Energy Consumption and Cost Implications

Hot forging typically consumes more energy due to the high temperatures required to heat metals above their recrystallization point, increasing fuel and operational costs. Cold forging, performed at or near room temperature, requires less energy but demands more powerful equipment and tooling, which can raise initial capital expenditures. While hot forging benefits from reduced material stress and lower die wear, cold forging offers cost savings in energy consumption but may incur higher maintenance and tooling replacement expenses.

Choosing the Right Forging Process for Your Project

Hot forging involves shaping metal at high temperatures, making it ideal for large, complex parts requiring significant deformation and improved ductility. Cold forging, performed at or near room temperature, offers superior surface finish, dimensional accuracy, and increased strength due to strain hardening, making it suitable for high-volume production of smaller components. Selecting the right forging process depends on factors such as material type, desired mechanical properties, dimensional tolerances, and production volume.

Recrystallization temperature

Hot forging occurs above the recrystallization temperature allowing dynamic grain refinement, while cold forging takes place below this temperature, resulting in strain hardening and increased material strength.

Grain refinement

Hot forging promotes significant grain refinement through dynamic recrystallization at elevated temperatures, whereas cold forging enhances grain strength by strain hardening without altering grain size.

Work hardening

Hot forging reduces work hardening through elevated temperatures allowing metal recrystallization, while cold forging increases work hardening due to deformation occurring below recrystallization temperature.

Flash formation

Hot forging typically produces significant flash formation due to material flow above recrystallization temperature, whereas cold forging generates minimal flash as the metal remains below recrystallization temperature, limiting excess material deformation.

Die lubrication

Effective die lubrication in hot forging minimizes friction and wear at elevated temperatures, whereas in cold forging, specialized lubricants are crucial to prevent galling and ensure smooth material flow under high pressure.

Flow stress

Hot forging significantly reduces flow stress compared to cold forging by increasing metal ductility and decreasing yield strength at elevated temperatures.

Billet preheating

Hot forging involves billet preheating to temperatures typically between 1100degF and 2300degF to enhance metal ductility and reduce deformation forces, while cold forging forgoes billet preheating, relying on ambient temperature conditions that increase metal strength and precision but require higher pressing forces.

Scale formation

Hot forging causes significant scale formation due to high temperatures oxidizing the metal surface, while cold forging minimizes scale formation by operating below the metal's recrystallization temperature.

Isothermal forging

Isothermal forging, a hot forging process performed at a controlled temperature to maintain material consistency, offers superior dimensional accuracy and mechanical properties compared to conventional hot and cold forging methods.

Dimensional tolerance

Cold forging typically achieves tighter dimensional tolerances compared to hot forging due to reduced thermal expansion and contraction during processing.

hot forging vs cold forging Infographic

njnir.com

njnir.com