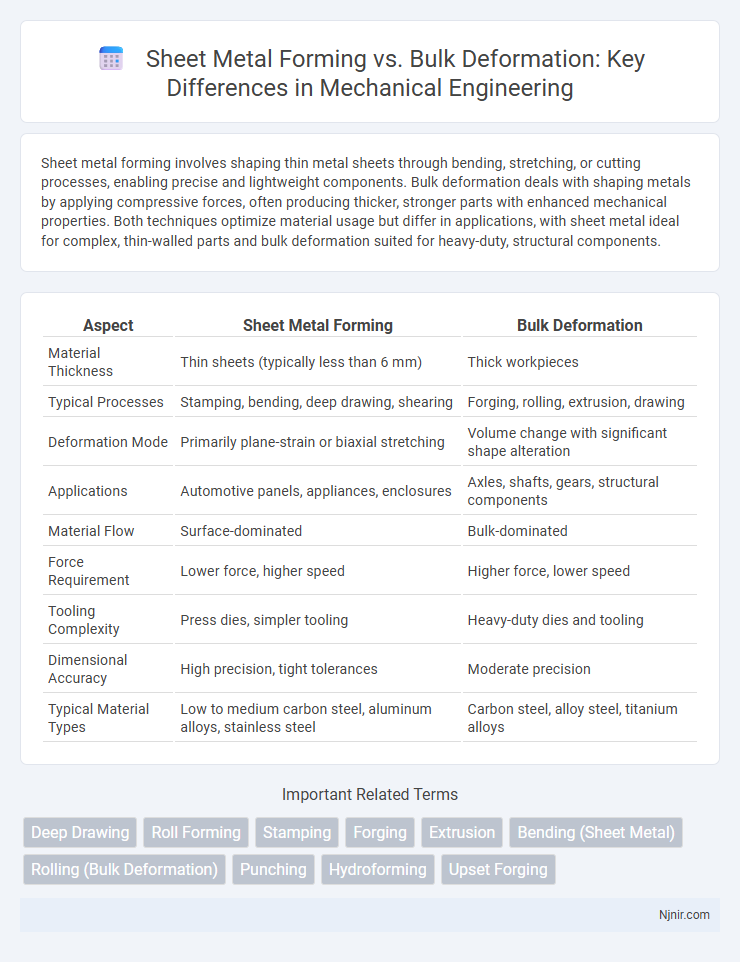

Sheet metal forming involves shaping thin metal sheets through bending, stretching, or cutting processes, enabling precise and lightweight components. Bulk deformation deals with shaping metals by applying compressive forces, often producing thicker, stronger parts with enhanced mechanical properties. Both techniques optimize material usage but differ in applications, with sheet metal ideal for complex, thin-walled parts and bulk deformation suited for heavy-duty, structural components.

Table of Comparison

| Aspect | Sheet Metal Forming | Bulk Deformation |

|---|---|---|

| Material Thickness | Thin sheets (typically less than 6 mm) | Thick workpieces |

| Typical Processes | Stamping, bending, deep drawing, shearing | Forging, rolling, extrusion, drawing |

| Deformation Mode | Primarily plane-strain or biaxial stretching | Volume change with significant shape alteration |

| Applications | Automotive panels, appliances, enclosures | Axles, shafts, gears, structural components |

| Material Flow | Surface-dominated | Bulk-dominated |

| Force Requirement | Lower force, higher speed | Higher force, lower speed |

| Tooling Complexity | Press dies, simpler tooling | Heavy-duty dies and tooling |

| Dimensional Accuracy | High precision, tight tolerances | Moderate precision |

| Typical Material Types | Low to medium carbon steel, aluminum alloys, stainless steel | Carbon steel, alloy steel, titanium alloys |

Introduction to Sheet Metal Forming and Bulk Deformation

Sheet metal forming involves shaping metal into thin, flat sections through processes such as bending, stamping, and deep drawing, which utilize plastic deformation without significant material volume change. Bulk deformation refers to shaping metals with substantial thickness changes via forging, extrusion, or rolling, emphasizing volume displacement and high strain. Both methods are essential in manufacturing but differ primarily in material thickness and deformation mechanics.

Fundamental Principles of Metal Forming Processes

Sheet metal forming involves plastic deformation of thin metal sheets primarily through bending, stretching, and shearing, relying on surface forces and strain distribution to achieve desired shapes. Bulk deformation processes, such as forging, extrusion, and rolling, manipulate much larger volumes of metal, emphasizing compressive forces and deformation throughout the metal's volume to alter its shape and properties. Both processes depend on controlling stress, strain, strain rate, and temperature to optimize formability, minimize defects, and tailor mechanical characteristics.

Material Behavior in Sheet Metal vs. Bulk Deformation

Material behavior in sheet metal forming is characterized by thin, flat sheets undergoing plastic deformation primarily through bending, stretching, and drawing, leading to localized strain and anisotropic properties. Bulk deformation involves substantial material volume changes with compressive, tensile, and shear stresses distributed throughout the material's cross-section, resulting in more homogeneous deformation and work hardening. The distinct stress states influence strain distribution, grain flow, and final mechanical properties, with sheet metals exhibiting higher strain localization compared to bulk materials.

Process Techniques: Overview and Distinctions

Sheet metal forming utilizes processes such as bending, deep drawing, and stretching to shape thin metal sheets, emphasizing surface precision and minimal thickness change. Bulk deformation involves techniques like forging, extrusion, and rolling, targeting significant shape and volume alteration in solid metal workpieces with high force application. The primary distinction lies in sheet metal forming's focus on altering surface geometry with less material volume change, whereas bulk deformation reshapes the entire material cross-section through substantial plastic deformation.

Common Applications in Industry

Sheet metal forming is widely used in automotive body panels, aerospace fuselage components, and household appliances due to its ability to produce thin, complex shapes with high precision. Bulk deformation finds common applications in manufacturing gears, shafts, and structural components where high strength and durability are essential. Both processes are integral in heavy machinery, construction equipment, and transportation industries for producing parts with distinct geometric and mechanical requirements.

Equipment and Tooling Requirements

Sheet metal forming requires specialized equipment such as presses, dies, and rollers designed for shaping thin metal sheets with precision, emphasizing tools like stamping dies, bending brakes, and rollers. Bulk deformation involves robust machines including forging presses, extrusion presses, and rolling mills capable of handling large volumes of metal with high force, relying on heavy-duty dies and molds to shape thick metal workpieces. Equipment for bulk deformation must withstand greater stresses and higher temperatures, while sheet metal forming tools prioritize accuracy and surface finish quality.

Advantages and Limitations of Each Method

Sheet metal forming offers high precision and the ability to produce complex shapes with uniform thickness, making it ideal for automotive and aerospace components. Its limitation lies in reduced material strength due to thinning and the generation of residual stresses, which may affect durability. Bulk deformation provides superior mechanical properties through work hardening and grain refinement but is constrained by higher energy consumption and less intricate shape capabilities.

Quality Control and Defect Prevention

Sheet metal forming involves precise control of surface finish and dimensional accuracy, requiring advanced quality control methods like laser scanning and automated defect detection to prevent surface cracks and wrinkles. Bulk deformation prioritizes maintaining material integrity and uniformity during large strain processes, utilizing real-time monitoring of temperature, strain rate, and hardness to minimize internal defects like voids and inclusions. Both processes benefit from statistical process control (SPC) and non-destructive testing (NDT) techniques to ensure consistent quality and reduce scrap rates.

Economic and Energy Considerations

Sheet metal forming generally consumes less energy compared to bulk deformation due to its lower material volume and thinner gauges, leading to reduced material costs and energy input. Bulk deformation processes, such as forging and extrusion, involve larger material volumes and higher forces, increasing both production costs and energy consumption. Energy-efficient operations in sheet metal forming contribute to faster processing times and lower expenses, making it more economically advantageous for high-volume manufacturing with detailed geometries.

Future Trends in Metal Forming Technologies

Future trends in metal forming technologies emphasize advanced sheet metal forming and bulk deformation methods integrated with Industry 4.0 principles such as smart sensors, AI-driven process control, and digital twins to enhance precision and reduce waste. Additive manufacturing hybrid processes are increasingly combined with traditional bulk deformation techniques like forging and extrusion to improve material properties and design flexibility. Emphasis on sustainable manufacturing drives the adoption of energy-efficient forming processes, lightweight materials, and real-time monitoring systems to boost productivity and reduce environmental impact.

Deep Drawing

Deep drawing, a key sheet metal forming process, precisely shapes metal sheets into complex, hollow forms by applying tensile and compressive stresses, offering superior surface finish and dimensional accuracy compared to bulk deformation methods that primarily involve volume changes in solid metals.

Roll Forming

Roll forming offers precise, continuous shaping of sheet metal through incremental bending, distinguishing itself from bulk deformation by minimizing material thinning and enabling complex, uniform cross-sections in high-volume production.

Stamping

Stamping, a key sheet metal forming process, efficiently shapes thin metal sheets by applying high pressure, contrasting bulk deformation techniques that manipulate thicker, more substantial metal volumes through processes like forging or extrusion.

Forging

Forging, a bulk deformation process, shapes metal by applying compressive forces to enhance strength and structural integrity, unlike sheet metal forming which primarily shapes thin metal sheets.

Extrusion

Extrusion, a bulk deformation process, involves forcing material through a die to create objects with a fixed cross-sectional profile, unlike sheet metal forming which reshapes thin metal sheets by bending or stretching without significantly altering thickness.

Bending (Sheet Metal)

Bending in sheet metal forming involves plastic deformation along a straight axis to create angular shapes without significantly altering the material thickness, distinguishing it from bulk deformation processes that primarily change volume and shape through compression or extrusion.

Rolling (Bulk Deformation)

Rolling, a bulk deformation process, efficiently reduces metal thickness by passing it between rotating rolls, enhancing mechanical properties and surface finish compared to sheet metal forming techniques.

Punching

Punching in sheet metal forming involves precise shearing of thin sheets using a punch and die, whereas bulk deformation focuses on shaping thicker metals through compressive forces without cutting.

Hydroforming

Hydroforming, a key sheet metal forming process, uses high-pressure hydraulic fluid to shape ductile metals into complex, lightweight components with enhanced strength compared to traditional bulk deformation methods.

Upset Forging

Upset forging, a bulk deformation process, enhances material strength and structural integrity by significantly increasing cross-sectional area through localized compressive forces, contrasting with sheet metal forming that primarily reshapes thin metal sheets with minimal thickness change.

Sheet metal forming vs bulk deformation Infographic

njnir.com

njnir.com