Virtual prototyping enables engineers to simulate and analyze mechanical designs using computer-aided tools, significantly reducing development time and costs compared to physical prototypes. Physical prototyping provides tangible models that allow for real-world testing and validation of mechanical functions, detecting issues that digital simulations might overlook. Combining both methods enhances design accuracy, accelerates innovation, and improves overall product performance in mechanical engineering projects.

Table of Comparison

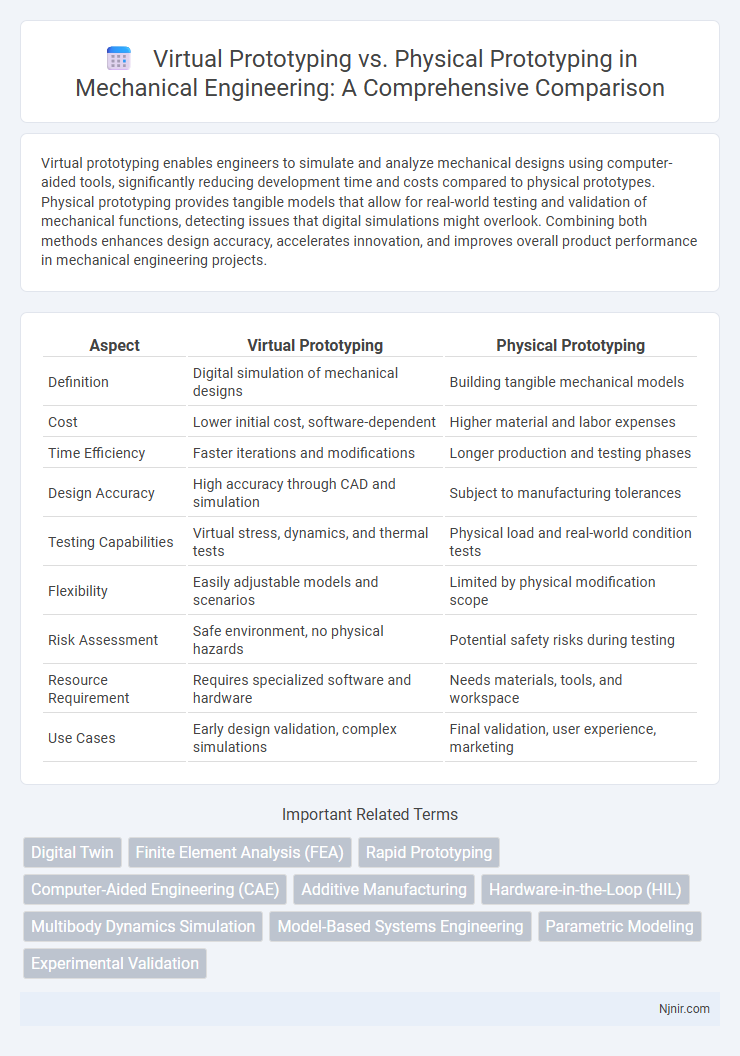

| Aspect | Virtual Prototyping | Physical Prototyping |

|---|---|---|

| Definition | Digital simulation of mechanical designs | Building tangible mechanical models |

| Cost | Lower initial cost, software-dependent | Higher material and labor expenses |

| Time Efficiency | Faster iterations and modifications | Longer production and testing phases |

| Design Accuracy | High accuracy through CAD and simulation | Subject to manufacturing tolerances |

| Testing Capabilities | Virtual stress, dynamics, and thermal tests | Physical load and real-world condition tests |

| Flexibility | Easily adjustable models and scenarios | Limited by physical modification scope |

| Risk Assessment | Safe environment, no physical hazards | Potential safety risks during testing |

| Resource Requirement | Requires specialized software and hardware | Needs materials, tools, and workspace |

| Use Cases | Early design validation, complex simulations | Final validation, user experience, marketing |

Introduction to Prototyping in Mechanical Engineering

Virtual prototyping leverages computer-aided design (CAD) and simulation software to create digital models of mechanical components, enabling rapid testing and modifications without physical materials. Physical prototyping involves fabricating tangible models or parts to evaluate real-world performance, material behavior, and assembly processes. Mechanical engineering integrates both methods to optimize design accuracy, reduce development time, and lower overall production costs.

Defining Virtual Prototyping

Virtual prototyping involves creating digital models of products using computer-aided design (CAD) and simulation software to test and refine designs before manufacturing. This approach enables rapid iteration, cost reduction, and early detection of design flaws by simulating real-world conditions virtually. Unlike physical prototyping, virtual prototypes eliminate the need for material resources and physical assembly in the initial stages, accelerating product development cycles.

Understanding Physical Prototyping

Physical prototyping involves creating tangible models that replicate the final product's form, fit, and function, allowing hands-on testing and real-world evaluation. This method facilitates direct observation of material properties, ergonomics, and assembly processes, which can reveal issues that digital simulations might overlook. Despite higher costs and longer development times compared to virtual prototyping, physical prototypes provide critical insights into manufacturability and user interaction.

Key Differences Between Virtual and Physical Prototyping

Virtual prototyping utilizes computer-aided design (CAD) and simulation software to create detailed digital models, enabling rapid testing and modification without material costs, whereas physical prototyping involves building tangible models that provide real-world functionality and tactile feedback. Virtual prototypes allow for early detection of design flaws and performance evaluation under various simulated conditions, while physical prototypes validate ergonomics, assembly processes, and manufacturing feasibility. The choice between virtual and physical prototyping depends on project requirements such as speed, cost, accuracy, and the need for hands-on assessment during product development.

Advantages of Virtual Prototyping

Virtual prototyping offers significant advantages by enabling rapid design iterations and real-time testing without the costs and delays associated with physical model construction. It allows for comprehensive simulations under diverse conditions, improving product performance prediction and reducing material waste. This approach accelerates time-to-market and enhances collaboration through digital sharing and modifications, ultimately lowering overall development expenses.

Benefits of Physical Prototyping

Physical prototyping offers tangible feedback through real-world testing, enabling accurate assessment of ergonomics, materials, and functionality that virtual models may overlook. It allows designers to identify unforeseen issues related to assembly, durability, and user interaction early in the development cycle. Hands-on evaluation fosters better communication among stakeholders and accelerates iterative improvements by providing a concrete reference point.

Limitations and Challenges: Virtual vs Physical Prototyping

Virtual prototyping faces limitations such as high initial software costs, computational power requirements, and potential inaccuracies in simulating complex real-world behaviors. Physical prototyping involves challenges including material costs, longer production time, and difficulty in making rapid iterations due to the tangible nature of the model. Both approaches struggle with user experience validation, but virtual prototyping excels in early design testing while physical prototypes provide more reliable performance feedback.

Cost and Time Considerations

Virtual prototyping significantly reduces development costs by minimizing the need for multiple physical models and allows for faster iterations through digital simulations. Physical prototyping involves higher expenses due to material, fabrication, and labor costs, often extending project timelines with longer production and testing phases. Efficient virtual prototyping accelerates design validation and reduces time-to-market compared to the traditional approach of building and modifying physical prototypes.

Industry Applications and Case Studies

Virtual prototyping enables industries like automotive and aerospace to accelerate design cycles and reduce costs by simulating performance under diverse conditions, enhancing product reliability without material expenses. Physical prototyping remains crucial in sectors such as medical device manufacturing, where tactile feedback and real-world testing validate ergonomics and safety compliance. Case studies from companies like Tesla demonstrate that integrating virtual prototyping with selective physical testing optimizes development efficiency and innovation outcomes.

Future Trends in Prototyping Methods

Virtual prototyping leverages advanced simulation technologies and AI-driven design tools to accelerate product development and reduce costs, while physical prototyping remains essential for tactile testing and real-world validation. Future trends indicate a hybrid approach combining augmented reality (AR) and digital twin technologies to enhance accuracy and collaboration across remote teams. Increasing integration of IoT sensors in prototypes will provide real-time data feedback, bridging the gap between virtual predictions and physical performance.

Digital Twin

Digital twin technology enables virtual prototyping by creating accurate real-time digital replicas of physical products, reducing the need for costly physical prototypes and accelerating design validation.

Finite Element Analysis (FEA)

Finite Element Analysis (FEA) in virtual prototyping enables precise simulation of stress, heat, and deformation in complex designs, significantly reducing time and cost compared to traditional physical prototyping.

Rapid Prototyping

Rapid prototyping using virtual prototyping accelerates product development by enabling instant design iterations and cost-efficient testing, unlike traditional physical prototyping that requires time-consuming and expensive material fabrication.

Computer-Aided Engineering (CAE)

Computer-Aided Engineering (CAE) enhances virtual prototyping by providing precise simulations and analyses that reduce the need for costly and time-consuming physical prototypes.

Additive Manufacturing

Additive manufacturing accelerates virtual prototyping by enabling rapid iterations and cost-effective design validation, reducing the need for multiple physical prototypes.

Hardware-in-the-Loop (HIL)

Hardware-in-the-Loop (HIL) testing enables virtual prototyping to simulate real-time hardware responses, reducing development time and costs compared to traditional physical prototyping.

Multibody Dynamics Simulation

Multibody dynamics simulation in virtual prototyping accelerates design validation by enabling precise analysis of complex mechanical interactions, reducing the need for costly and time-consuming physical prototypes.

Model-Based Systems Engineering

Model-Based Systems Engineering (MBSE) enhances virtual prototyping by enabling comprehensive system simulations and early validation, reducing the need for costly physical prototyping and accelerating product development cycles.

Parametric Modeling

Parametric modeling in virtual prototyping enables rapid design iterations and real-time adjustments, significantly reducing costs and development time compared to traditional physical prototyping.

Experimental Validation

Experimental validation in virtual prototyping enables faster iteration and cost-effective testing by simulating real-world conditions, whereas physical prototyping provides direct tactile feedback and empirical data critical for final product verification.

Virtual prototyping vs physical prototyping Infographic

njnir.com

njnir.com