Rolling resistance is significantly lower than sliding friction due to the reduced deformation between surfaces in contact, which minimizes energy loss. Unlike sliding friction that involves direct surface-to-surface contact causing higher wear and heat generation, rolling resistance primarily results from the hysteresis in the materials involved. Optimizing mechanical systems by focusing on rolling elements reduces energy consumption and improves overall efficiency in engineering applications.

Table of Comparison

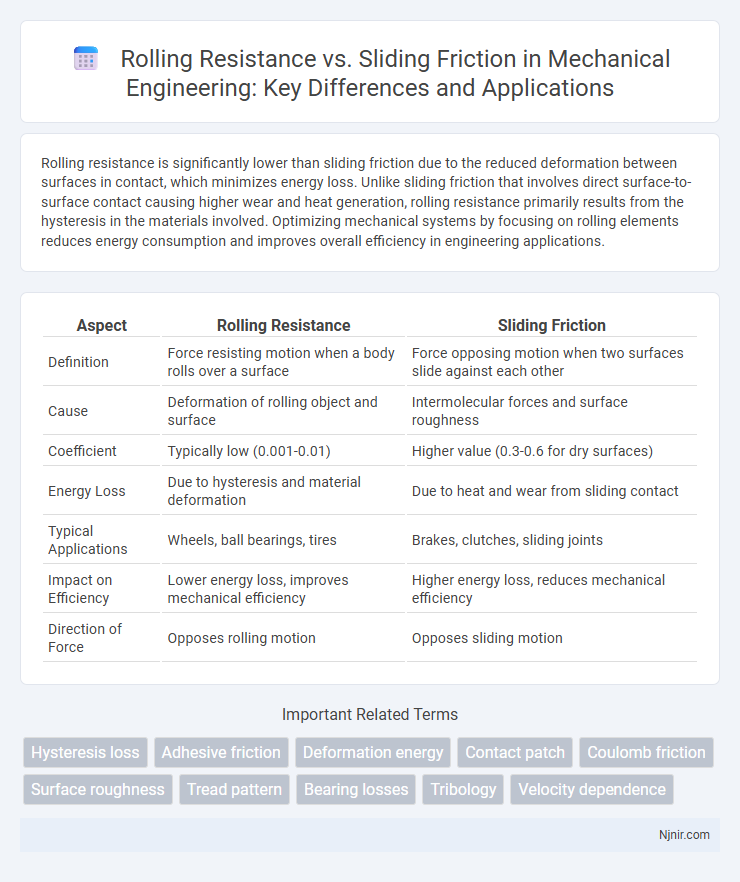

| Aspect | Rolling Resistance | Sliding Friction |

|---|---|---|

| Definition | Force resisting motion when a body rolls over a surface | Force opposing motion when two surfaces slide against each other |

| Cause | Deformation of rolling object and surface | Intermolecular forces and surface roughness |

| Coefficient | Typically low (0.001-0.01) | Higher value (0.3-0.6 for dry surfaces) |

| Energy Loss | Due to hysteresis and material deformation | Due to heat and wear from sliding contact |

| Typical Applications | Wheels, ball bearings, tires | Brakes, clutches, sliding joints |

| Impact on Efficiency | Lower energy loss, improves mechanical efficiency | Higher energy loss, reduces mechanical efficiency |

| Direction of Force | Opposes rolling motion | Opposes sliding motion |

Introduction to Rolling Resistance and Sliding Friction

Rolling resistance arises when a rolling object, such as a tire or wheel, deforms at the contact surface, causing energy loss primarily through material hysteresis and surface interactions. Sliding friction occurs when two surfaces slide past each other, generating resistance proportional to the normal force and characterized by the coefficient of kinetic friction between the materials. Understanding the fundamental differences between rolling resistance, which depends on deformation and energy dissipation, and sliding friction, which depends on surface roughness and shear forces, is crucial for optimizing vehicle efficiency and mechanical system performance.

Fundamental Concepts: Definitions and Differences

Rolling resistance refers to the energy lost when a round object, such as a wheel or ball, rolls over a surface, primarily caused by deformation of the wheel or surface material. Sliding friction, or kinetic friction, occurs when two surfaces slide against each other, generating resistance due to microscopic interlocking and surface roughness. The fundamental difference lies in the nature of motion--rolling resistance involves rotational movement with minimal surface contact deformation, while sliding friction involves direct surface contact and relative motion, leading to higher frictional forces.

Physical Principles Behind Rolling and Sliding

Rolling resistance arises from the deformation of both the rolling object and the surface it moves on, causing energy loss primarily through hysteresis within the materials. Sliding friction is governed by the interaction of microscopic asperities between two contacting surfaces, resulting in resistive force proportional to the normal load. The key physical difference is that rolling involves continuous deformation and recovery cycles, while sliding entails direct surface shear and interlocking irregularities.

Factors Affecting Rolling Resistance

Rolling resistance is primarily influenced by factors such as the deformation of the wheel and surface materials, wheel diameter, and tire pressure, which affect energy loss during motion. Surface roughness and material elasticity also play critical roles, with softer surfaces and materials increasing rolling resistance due to greater deformation. Temperature and load further impact rolling resistance by altering the mechanical properties of both the wheel and the contact surface.

Key Influences on Sliding Friction

Sliding friction depends heavily on surface roughness, material composition, and the normal force between the contact surfaces. The microscopic interlocking of asperities and adhesive forces at the interface majorly influence the frictional resistance during sliding. Temperature and lubrication presence also significantly affect sliding friction by altering the contact mechanics and reducing surface adhesion.

Measurement and Quantification Techniques

Rolling resistance is typically measured using a rotational drum or a conveyor belt setup where force sensors quantify the torque required to maintain constant motion, enabling calculation of rolling resistance coefficient. Sliding friction is quantified through tribometers or friction testers that record the lateral force opposing motion between two sliding surfaces, allowing precise determination of the coefficient of friction. Advanced techniques such as dynamometers and strain gauge sensors improve accuracy in both scenarios by providing real-time force data under controlled environmental conditions.

Typical Materials and Surface Interactions

Rolling resistance typically occurs between rigid wheels or cylinders and smooth surfaces like asphalt or concrete, where deformation of the contact area primarily causes energy loss. Sliding friction involves surfaces like rubber on rough pavement or metal on metal, where microscopic asperities interlock and resist motion, generating higher energy dissipation compared to rolling resistance. Common materials such as steel wheels on steel rails exhibit low rolling resistance due to minimal deformation, whereas rubber tires on asphalt show higher rolling resistance and sliding friction depending on surface texture and load.

Energy Losses and Efficiency Implications

Rolling resistance typically results in lower energy losses compared to sliding friction due to reduced deformation and heat generation at the contact interface. Sliding friction causes higher energy dissipation because of continuous surface asperity interlocking and abrasive wear, leading to decreased mechanical efficiency. Optimizing rolling elements in machinery and transportation systems enhances fuel economy and performance by minimizing frictional losses and improving overall energy efficiency.

Real-World Applications in Mechanical Engineering

Rolling resistance in mechanical engineering significantly reduces energy losses in applications such as vehicle tires, conveyor rollers, and ball bearings, enhancing efficiency and durability. Sliding friction, characterized by higher resistance and wear, is critical in braking systems, clutches, and machining processes where controlled friction is essential. Optimizing rolling resistance improves fuel efficiency and lifespan, while managing sliding friction ensures precise motion control and material integrity in mechanical designs.

Comparative Analysis: Optimization Strategies

Rolling resistance is significantly lower than sliding friction due to reduced contact area and deformation energy loss, making it the preferred mode in vehicle and conveyor system optimization. Surface material engineering, such as using advanced polymers or textured coatings, minimizes sliding friction by reducing micro-adhesion and plowing effects. Optimization strategies prioritize rolling elements like ball or roller bearings to enhance energy efficiency and durability compared to sliding interfaces.

Hysteresis loss

Rolling resistance primarily arises from hysteresis loss due to repeated deformation of the tire material, whereas sliding friction results from surface shear forces with minimal hysteresis contribution.

Adhesive friction

Adhesive friction significantly influences sliding friction by increasing resistance through molecular bonding at contact surfaces, whereas rolling resistance primarily depends on deformation and energy loss in the rolling object's material.

Deformation energy

Rolling resistance primarily arises from deformation energy losses in the rolling object and surface, while sliding friction largely involves energy dissipation through surface asperity interactions and shearing.

Contact patch

The contact patch size directly influences rolling resistance by reducing deformation losses, whereas sliding friction depends primarily on the shear forces at the contact interface regardless of contact patch dimensions.

Coulomb friction

Rolling resistance is generally lower than sliding friction because Coulomb friction, which governs sliding friction, involves constant resistive forces proportional to the normal load, whereas rolling resistance depends on deformation and energy losses at the contact patch.

Surface roughness

Rolling resistance is generally lower than sliding friction because the deformation of surface roughness during rolling dissipates less energy than the continuous surface asperity interlocking and plowing that occurs in sliding friction.

Tread pattern

Tread pattern significantly affects rolling resistance by optimizing contact area and deformation, while sliding friction is more influenced by surface texture and material interaction.

Bearing losses

Rolling resistance in bearings primarily results from micro-deformations and material hysteresis, causing significantly lower energy losses compared to the higher sliding friction generated by direct surface-to-surface contact.

Tribology

Rolling resistance in tribology is significantly lower than sliding friction due to reduced surface deformation and energy dissipation during wheel or ball bearings' rotation compared to the continuous surface contact and material wear in sliding friction.

Velocity dependence

Rolling resistance decreases with increasing velocity due to reduced deformation time, while sliding friction remains relatively constant regardless of velocity.

Rolling resistance vs sliding friction Infographic

njnir.com

njnir.com