Magnetic bearings offer frictionless operation and reduced maintenance compared to traditional ball bearings, improving efficiency and lifespan in mechanical systems. Their non-contact design eliminates wear and contamination risks, making them ideal for high-speed and precision applications. However, magnetic bearings typically require complex control systems and higher initial investment, which can limit their use in cost-sensitive projects.

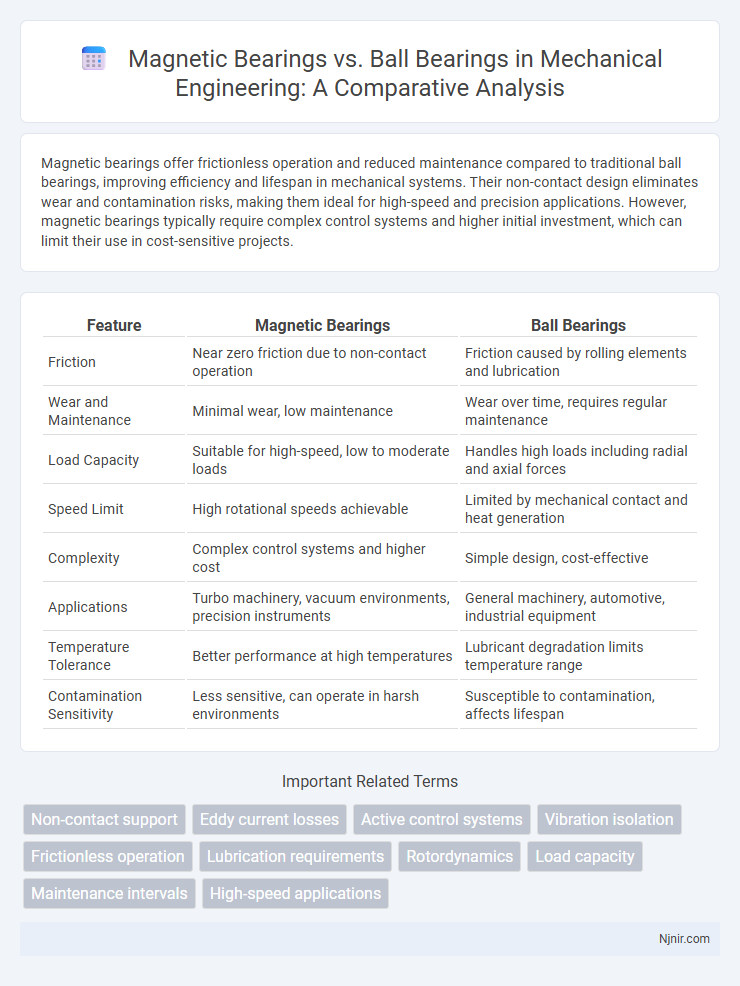

Table of Comparison

| Feature | Magnetic Bearings | Ball Bearings |

|---|---|---|

| Friction | Near zero friction due to non-contact operation | Friction caused by rolling elements and lubrication |

| Wear and Maintenance | Minimal wear, low maintenance | Wear over time, requires regular maintenance |

| Load Capacity | Suitable for high-speed, low to moderate loads | Handles high loads including radial and axial forces |

| Speed Limit | High rotational speeds achievable | Limited by mechanical contact and heat generation |

| Complexity | Complex control systems and higher cost | Simple design, cost-effective |

| Applications | Turbo machinery, vacuum environments, precision instruments | General machinery, automotive, industrial equipment |

| Temperature Tolerance | Better performance at high temperatures | Lubricant degradation limits temperature range |

| Contamination Sensitivity | Less sensitive, can operate in harsh environments | Susceptible to contamination, affects lifespan |

Introduction to Bearing Technologies in Mechanical Engineering

Magnetic bearings utilize electromagnetic forces to support loads without physical contact, offering advantages such as reduced friction, high rotational speeds, and minimal maintenance compared to traditional ball bearings. Ball bearings rely on rolling elements to minimize friction between moving parts but exhibit wear and require lubrication for optimal performance. In mechanical engineering, understanding these technologies is crucial for selecting appropriate bearing types based on applications involving speed, load, precision, and maintenance requirements.

Overview of Magnetic Bearings

Magnetic bearings support rotating machinery using magnetic fields to levitate the shaft without physical contact, reducing friction and wear compared to traditional ball bearings. These bearings enable higher rotational speeds, lower maintenance, and improved reliability in applications such as turbines, compressors, and flywheels. Magnetic bearings also offer precise rotor positioning and vibration control, enhancing system efficiency and lifespan.

Overview of Ball Bearings

Ball bearings consist of hardened steel balls positioned between two concentric rings, called races, enabling smooth rotational movement while minimizing friction. These bearings excel in reliability, durability, and ability to handle radial and axial loads in various industrial applications. Their mechanical simplicity and widespread availability make ball bearings a cost-effective choice for traditional machinery compared to magnetic bearings.

Key Functional Differences

Magnetic bearings utilize electromagnetic fields to levitate and support rotating shafts without physical contact, resulting in minimal friction and wear, whereas ball bearings rely on rolling elements positioned between inner and outer rings to reduce friction through mechanical contact. Magnetic bearings offer superior performance in high-speed applications and environments requiring contamination-free operation, while ball bearings are more common, cost-effective, and suitable for moderate speeds and loads. The lack of mechanical contact in magnetic bearings also enables reduced maintenance and longer operational lifespans compared to traditional ball bearings.

Load Capacity and Performance Comparison

Magnetic bearings offer superior load capacity by supporting both radial and axial forces without physical contact, reducing wear and enabling higher rotational speeds compared to traditional ball bearings. Ball bearings rely on rolling elements to carry loads but face limitations in high-speed applications due to friction and heat generation. Performance-wise, magnetic bearings provide enhanced precision, lower maintenance costs, and longer operational life, making them ideal for high-speed turbines and advanced machinery requiring minimal vibration and high reliability.

Maintenance Requirements and Longevity

Magnetic bearings require minimal maintenance due to the absence of physical contact, reducing wear and eliminating the need for lubrication, which significantly extends their operational lifespan compared to traditional ball bearings. Ball bearings experience friction and wear over time, necessitating regular lubrication, inspection, and eventual replacement to maintain performance. Consequently, magnetic bearings offer superior longevity and lower maintenance costs in high-speed, precision applications.

Applications and Industry Use Cases

Magnetic bearings are extensively utilized in high-speed applications such as turbomachinery, flywheel energy storage, and vacuum pumps due to their frictionless operation and minimal maintenance requirements. Ball bearings remain prevalent in automotive, aerospace, and industrial machinery where robust load capacity and lower initial costs are critical. Industries like semiconductor manufacturing and medical equipment increasingly adopt magnetic bearings for precision and reduced contamination risks, whereas ball bearings dominate conventional applications needing durability and widespread availability.

Efficiency and Energy Consumption

Magnetic bearings offer superior efficiency compared to ball bearings due to their near-frictionless operation, significantly reducing energy consumption in high-speed applications. Unlike ball bearings that experience mechanical friction and require lubrication, magnetic bearings use electromagnetic fields to levitate the rotor, minimizing power losses and maintenance needs. This leads to enhanced performance in precision equipment and energy-saving benefits, especially in industrial turbines and electric motors.

Cost Considerations and Economic Impact

Magnetic bearings generally have higher initial costs due to advanced technology and precise manufacturing requirements, while ball bearings offer lower upfront expenses and widespread availability. Maintenance expenses for magnetic bearings are reduced by the absence of frictional wear, leading to longer service life and decreased downtime costs in industrial applications. Over time, the energy efficiency and reliability of magnetic bearings can offset their initial investment, making them economically advantageous in high-performance or continuous-operation environments.

Future Trends in Bearing Technology

Magnetic bearings are emerging as a key innovation in bearing technology, offering frictionless operation and enhanced lifespan compared to traditional ball bearings. Future trends highlight the integration of smart sensors with magnetic bearings for predictive maintenance and real-time performance monitoring in industries such as aerospace and renewable energy. Advances in materials science and control algorithms are expected to further improve efficiency, reliability, and adaptability of magnetic bearing systems, potentially surpassing the capabilities of conventional ball bearings.

Non-contact support

Magnetic bearings provide non-contact support through electromagnetic fields, eliminating friction and wear compared to the mechanical contact found in ball bearings.

Eddy current losses

Magnetic bearings significantly reduce Eddy current losses compared to ball bearings by eliminating physical contact and minimizing conductive material interactions in rotating machinery.

Active control systems

Magnetic bearings utilize active control systems with sensors and electromagnets to dynamically stabilize rotating components, offering lower friction and maintenance compared to traditional ball bearings.

Vibration isolation

Magnetic bearings provide superior vibration isolation compared to ball bearings by minimizing contact and friction, resulting in reduced noise and increased precision in high-speed rotating machinery.

Frictionless operation

Magnetic bearings provide frictionless operation by levitating the rotor using magnetic fields, eliminating contact and wear found in traditional ball bearings.

Lubrication requirements

Magnetic bearings require no lubrication due to their contactless operation, whereas ball bearings depend on continuous lubrication to minimize friction and wear.

Rotordynamics

Magnetic bearings offer superior rotordynamics performance by enabling frictionless, contact-free operation that reduces vibration and wear compared to traditional ball bearings.

Load capacity

Magnetic bearings offer higher load capacity and lower friction compared to ball bearings, enabling superior performance in heavy-duty and precision applications.

Maintenance intervals

Magnetic bearings require significantly longer maintenance intervals than ball bearings due to their non-contact operation, which reduces wear and eliminates the need for lubrication.

High-speed applications

Magnetic bearings enable high-speed applications by offering frictionless operation, reduced wear, and enhanced rotational precision compared to traditional ball bearings.

magnetic bearings vs ball bearings Infographic

njnir.com

njnir.com