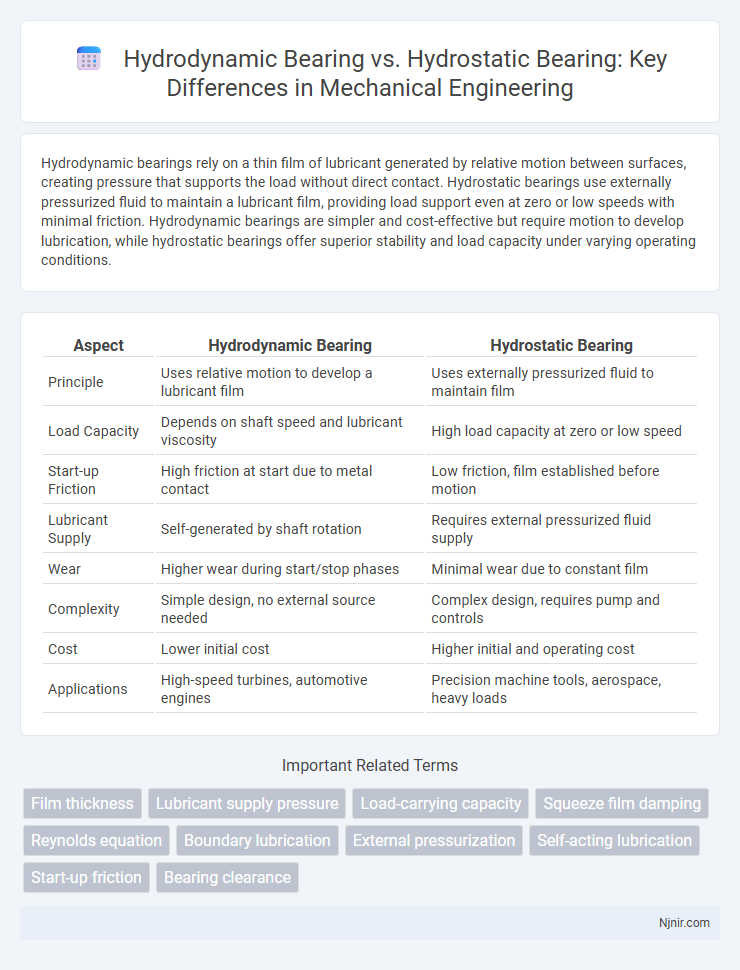

Hydrodynamic bearings rely on a thin film of lubricant generated by relative motion between surfaces, creating pressure that supports the load without direct contact. Hydrostatic bearings use externally pressurized fluid to maintain a lubricant film, providing load support even at zero or low speeds with minimal friction. Hydrodynamic bearings are simpler and cost-effective but require motion to develop lubrication, while hydrostatic bearings offer superior stability and load capacity under varying operating conditions.

Table of Comparison

| Aspect | Hydrodynamic Bearing | Hydrostatic Bearing |

|---|---|---|

| Principle | Uses relative motion to develop a lubricant film | Uses externally pressurized fluid to maintain film |

| Load Capacity | Depends on shaft speed and lubricant viscosity | High load capacity at zero or low speed |

| Start-up Friction | High friction at start due to metal contact | Low friction, film established before motion |

| Lubricant Supply | Self-generated by shaft rotation | Requires external pressurized fluid supply |

| Wear | Higher wear during start/stop phases | Minimal wear due to constant film |

| Complexity | Simple design, no external source needed | Complex design, requires pump and controls |

| Cost | Lower initial cost | Higher initial and operating cost |

| Applications | High-speed turbines, automotive engines | Precision machine tools, aerospace, heavy loads |

Introduction to Fluid Film Bearings

Fluid film bearings, including hydrodynamic and hydrostatic types, rely on a thin layer of lubricant to support loads and reduce friction between moving surfaces. Hydrodynamic bearings generate a pressure wedge through relative motion, creating a self-sustaining lubricating film without external pressure. Hydrostatic bearings maintain a pressurized film by externally supplying lubricant under pressure, enabling load support even at zero or low speeds.

Principles of Hydrodynamic Bearings

Hydrodynamic bearings operate based on the principle of a fluid film generated by the relative motion between the bearing surface and the shaft, where the fluid pressure supports the load without direct contact. This leads to a self-acting lubrication mechanism that creates a wedge-shaped film, preventing metal-to-metal contact and reducing friction and wear. Hydrodynamic bearings differ from hydrostatic bearings, which rely on externally pressurized fluid to maintain the fluid film regardless of motion.

Principles of Hydrostatic Bearings

Hydrostatic bearings operate on the principle of externally pressurized fluid film that supports the load independently of motion, maintaining a constant film thickness and minimizing metal-to-metal contact. These bearings use a pump to supply pressurized lubricant, creating a stable fluid cushion that absorbs high loads and reduces friction even at zero speed. This external pressurization contrasts with hydrodynamic bearings, which rely on relative motion to generate fluid pressure and support loads.

Key Differences Between Hydrodynamic and Hydrostatic Bearings

Hydrodynamic bearings rely on the relative motion between the bearing surfaces to generate a lubricating film, creating a pressure that supports the load, whereas hydrostatic bearings use an external pump to supply pressurized lubricant continuously, maintaining a fluid film independently of motion. Hydrodynamic bearings typically exhibit higher friction and wear during startup and low-speed conditions, while hydrostatic bearings provide near-zero wear and friction regardless of speed due to constant lubrication. Load capacity in hydrostatic bearings is generally higher and more consistent, making them suitable for precision applications requiring stable, vibration-free operation.

Performance Comparison: Load Capacity and Stiffness

Hydrostatic bearings provide superior load capacity due to the external pressurized fluid supply maintaining a consistent lubricating film regardless of shaft speed, enabling them to support heavier loads with minimal deformation. Hydrodynamic bearings rely on the relative motion between surfaces to generate a lubricating wedge, resulting in increased stiffness at higher speeds but reduced load capacity at low or zero speeds. Consequently, hydrostatic bearings exhibit higher stiffness and better load-bearing performance under static and low-speed conditions, while hydrodynamic bearings optimize stiffness through velocity-dependent fluid film formation during operation.

Lubrication Systems and Fluid Supply Requirements

Hydrodynamic bearings rely on a continuous fluid film generated by relative motion between the shaft and bearing surface, requiring minimal external lubrication systems as the motion itself maintains the lubricant film. Hydrostatic bearings demand an external pressurized fluid supply to maintain a consistent lubricant film regardless of shaft movement, necessitating complex lubrication systems with pumps and filters to ensure stable fluid flow and pressure. The precise control of fluid supply in hydrostatic bearings enables higher load capacity and stiffness, whereas hydrodynamic bearings depend on shaft speed and viscosity to sustain lubrication.

Applications in Mechanical Engineering

Hydrodynamic bearings are widely used in applications such as turbines, internal combustion engines, and electric motors where high-speed rotation and load capacity are critical, relying on a lubricating film generated by shaft movement to reduce friction. Hydrostatic bearings find application in precision machining tools, aerospace equipment, and large industrial compressors, offering superior stiffness and accuracy by actively supplying pressurized lubricant to support the load. Mechanical engineers select hydrodynamic bearings for cost-effectiveness and durability in high-speed environments, while hydrostatic bearings are preferred for enhanced performance in low-speed, high-precision scenarios.

Advantages and Limitations of Hydrodynamic Bearings

Hydrodynamic bearings offer the advantage of self-lubrication through the formation of a fluid film, which reduces friction and wear, enabling high-speed operation with minimal maintenance. Their limitations include sensitivity to start-stop conditions where the fluid film may not form properly, leading to metal-to-metal contact and potential damage. They also require precise alignment and a constant supply of lubricant to maintain performance and prevent overheating.

Advantages and Limitations of Hydrostatic Bearings

Hydrostatic bearings offer superior load capacity and stiffness by maintaining a pressurized fluid film independent of relative motion, effectively minimizing friction and wear during shaft operation. Their primary limitations include the requirement for an external pump system, leading to increased complexity, maintenance, and energy consumption compared to hydrodynamic bearings, which rely on relative motion to generate the lubricating film. Hydrostatic bearings excel in applications demanding high precision and stability but are less efficient in low-load or high-speed scenarios due to the constant energy input needed to maintain fluid pressure.

Selection Criteria for Bearing Types in Engineering Design

Hydrodynamic bearings rely on relative motion to generate a lubricating film, making them suitable for applications with continuous shaft rotation and moderate loads, while hydrostatic bearings use external pressurized fluid for load support, ideal for high-precision and heavy-load conditions with minimal friction start-up. Selection criteria in engineering design prioritize load capacity, stiffness, operating speed, lubrication quality, and start-up friction, with hydrostatic bearings favored for high accuracy and low vibration environments, and hydrodynamic bearings chosen for simpler systems with cost and maintenance constraints. Material compatibility, thermal management, and system complexity also influence the decision between these bearing types.

Film thickness

Hydrodynamic bearings rely on relative motion to generate a lubricant film thickness typically ranging from 1 to 10 micrometers, whereas hydrostatic bearings maintain a thicker, constant lubricant film often exceeding 50 micrometers through externally pressurized fluid supply.

Lubricant supply pressure

Hydrodynamic bearings rely on relative motion to generate lubricant supply pressure through fluid film formation, whereas hydrostatic bearings maintain a constant external lubricant supply pressure independent of shaft movement.

Load-carrying capacity

Hydrostatic bearings provide higher load-carrying capacity than hydrodynamic bearings due to external pressurized fluid supply maintaining a consistent lubricating film under varying loads.

Squeeze film damping

Hydrostatic bearings provide superior squeeze film damping compared to hydrodynamic bearings due to their externally pressurized lubricant film that maintains consistent thickness and load support.

Reynolds equation

Hydrodynamic bearings rely on the Reynolds equation to generate a pressure film through relative motion, while hydrostatic bearings use an external fluid supply to maintain film pressure independent of motion.

Boundary lubrication

Hydrodynamic bearings generate a lubricant film through relative motion creating boundary lubrication zones during startup and shutdown, while hydrostatic bearings maintain a full lubricant film via external pressurization, minimizing boundary lubrication entirely.

External pressurization

Hydrostatic bearings use external pressurization to supply a continuous flow of pressurized fluid for load support and reduced friction, whereas hydrodynamic bearings rely on relative motion to generate pressure internally without external fluid supply.

Self-acting lubrication

Self-acting lubrication in hydrodynamic bearings generates a fluid film through shaft rotation to support loads, whereas hydrostatic bearings rely on external pressurized fluid supply for lubrication and load support.

Start-up friction

Hydrodynamic bearings have higher start-up friction due to the lack of a lubricant film at rest, while hydrostatic bearings maintain low start-up friction by using externally pressurized lubricant to support the load immediately.

Bearing clearance

Hydrodynamic bearings maintain a thin fluid film through relative motion with minimal clearance, while hydrostatic bearings use externally pressurized fluid to support the load, allowing larger and controlled bearing clearance for enhanced stability.

Hydrodynamic bearing vs hydrostatic bearing Infographic

njnir.com

njnir.com