Nanomaterials exhibit unique mechanical, electrical, and thermal properties due to their nanoscale dimensions, enabling enhanced strength, conductivity, and reactivity compared to traditional composites. Composite materials combine two or more distinct phases to achieve superior mechanical performance, often prioritizing macroscopic strength and durability over nanoscale effects. Advancements in integrating nanomaterials into composite matrices significantly improve overall mechanical characteristics, including stiffness, toughness, and resistance to fatigue.

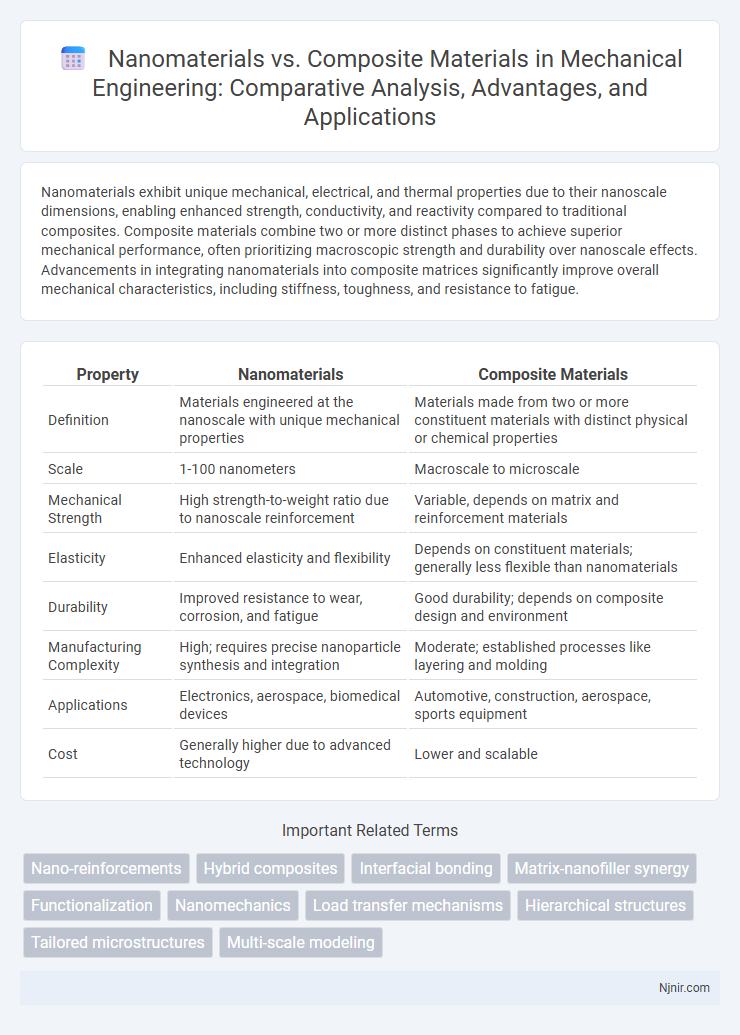

Table of Comparison

| Property | Nanomaterials | Composite Materials |

|---|---|---|

| Definition | Materials engineered at the nanoscale with unique mechanical properties | Materials made from two or more constituent materials with distinct physical or chemical properties |

| Scale | 1-100 nanometers | Macroscale to microscale |

| Mechanical Strength | High strength-to-weight ratio due to nanoscale reinforcement | Variable, depends on matrix and reinforcement materials |

| Elasticity | Enhanced elasticity and flexibility | Depends on constituent materials; generally less flexible than nanomaterials |

| Durability | Improved resistance to wear, corrosion, and fatigue | Good durability; depends on composite design and environment |

| Manufacturing Complexity | High; requires precise nanoparticle synthesis and integration | Moderate; established processes like layering and molding |

| Applications | Electronics, aerospace, biomedical devices | Automotive, construction, aerospace, sports equipment |

| Cost | Generally higher due to advanced technology | Lower and scalable |

Introduction to Nanomaterials and Composite Materials

Nanomaterials are materials engineered at the nanoscale, typically between 1 and 100 nanometers, offering unique mechanical, electrical, and optical properties due to their high surface area and quantum effects. Composite materials consist of two or more distinct phases, such as a matrix and reinforcement, combined to achieve superior performance characteristics like enhanced strength, stiffness, and durability. The integration of nanomaterials into composites leads to advanced nanocomposites, providing improved multifunctional properties for applications in aerospace, electronics, and biomedicine.

Fundamental Differences in Structure and Composition

Nanomaterials are engineered at the atomic or molecular scale, typically below 100 nanometers, featuring unique quantum-mechanical properties and high surface area-to-volume ratios. Composite materials consist of two or more distinct phases, such as fibers embedded in a matrix, designed to achieve superior mechanical, thermal, or electrical properties through macroscopic structural integration. Nanomaterials primarily manipulate material behavior at the nanoscale level, while composites combine diverse materials at the microscale or larger to optimize overall performance.

Manufacturing Techniques: Nanomaterials vs Composite Materials

Manufacturing nanomaterials involves techniques such as chemical vapor deposition, molecular self-assembly, and atomic layer deposition to achieve precise nanoscale control and uniformity. Composite materials are typically fabricated using methods like hand lay-up, resin transfer molding, and filament winding, which combine different material phases to enhance mechanical properties. The key distinction lies in nanomaterials requiring advanced, nanoscale-specific processes, while composite materials rely on macroscopic techniques for heterogeneous phase integration.

Mechanical Properties Comparison

Nanomaterials exhibit superior mechanical properties such as higher strength, stiffness, and toughness at the nanoscale due to their increased surface area to volume ratio and reduced defect density. Composite materials combine two or more constituent phases to achieve enhanced mechanical performance, balancing strength, flexibility, and durability tailored for specific applications. Compared to traditional composites, nanocomposites integrate nanomaterials as reinforcements, resulting in improved mechanical behavior including increased tensile strength, impact resistance, and fatigue life.

Role in Strengthening and Toughening Mechanisms

Nanomaterials enhance strengthening and toughening mechanisms by providing a high surface area-to-volume ratio that improves load transfer and deflects crack propagation at the nanoscale. Composite materials combine different phases, such as fibers and matrices, to synergistically improve strength and fracture toughness through mechanisms like fiber pull-out, matrix cracking, and crack bridging. The integration of nanomaterials into composites creates hybrid systems that exploit nanoscale reinforcement and microscale toughening, resulting in superior mechanical performance.

Applications in Mechanical Engineering Fields

Nanomaterials offer exceptional strength-to-weight ratios and enhanced thermal stability, making them ideal for high-performance mechanical components such as nanoscale coatings, sensors, and reinforcement agents in aerospace and automotive industries. Composite materials combine fibers like carbon or glass with polymer matrices to create structures with superior stiffness, impact resistance, and fatigue durability, widely used in structural parts, mechanical joints, and load-bearing elements. Both nanomaterials and composites contribute to advancements in mechanical engineering by improving performance, reducing weight, and increasing the longevity of mechanical systems.

Durability and Lifespan Considerations

Nanomaterials exhibit superior durability due to their nanoscale structure, which enhances mechanical strength and resistance to wear and corrosion compared to traditional composite materials. Composite materials, while offering good lifespan benefits through tailored fiber-matrix combinations, often face degradation issues in harsh environments that nanomaterials can better withstand. The integration of nanomaterials into composites further extends the lifespan by improving toughness and resistance to environmental stresses.

Environmental Impact and Sustainability

Nanomaterials offer enhanced performance with minimal material usage, reducing resource consumption and waste generation compared to traditional composite materials. However, the environmental impact of nanomaterials is still under study due to potential toxicity and challenges in recycling processes. Composite materials, while durable and lightweight, often involve energy-intensive manufacturing and difficulties in end-of-life disposal, making nanomaterials increasingly attractive for sustainable industrial applications.

Cost-Benefit Analysis in Industrial Applications

Nanomaterials offer enhanced mechanical, thermal, and electrical properties at nanoscale, leading to superior performance in industrial applications, but often come with higher production costs due to complex synthesis and scalability challenges. Composite materials provide a cost-effective alternative, combining various constituents to achieve tailored properties while benefiting from established manufacturing processes and lower raw material expenses. A cost-benefit analysis reveals that nanomaterials are justified in high-value, precision-focused industries, whereas composites remain advantageous in large-scale, cost-sensitive sectors requiring balanced performance and affordability.

Future Trends and Innovations

Nanomaterials and composite materials are advancing rapidly due to innovations in nano-reinforcement techniques and multi-scale material design, enabling enhanced mechanical strength, thermal stability, and electrical conductivity. Future trends highlight the integration of smart nanocomposites with self-healing properties, lightweight structures for aerospace, and bio-compatible materials for medical applications. Emerging techniques like 3D printing combined with nanotechnology are set to revolutionize the customization and scalability of composite fabrication.

Nano-reinforcements

Nano-reinforcements in nanomaterials significantly enhance mechanical, thermal, and electrical properties compared to traditional composite materials by providing superior surface area-to-volume ratios and interfacial bonding.

Hybrid composites

Hybrid composites combine nanomaterials with traditional composite materials to enhance mechanical strength, thermal stability, and durability for advanced engineering applications.

Interfacial bonding

Nanomaterials exhibit stronger interfacial bonding than composite materials due to their high surface area-to-volume ratio enhancing adhesion and mechanical properties.

Matrix-nanofiller synergy

Matrix-nanofiller synergy in nanomaterials significantly enhances mechanical, thermal, and electrical properties compared to traditional composite materials by optimizing interfacial interactions and stress transfer efficiency.

Functionalization

Functionalization of nanomaterials enhances their surface properties for targeted applications, while composite materials rely on functionalization to improve interfacial bonding and overall mechanical performance.

Nanomechanics

Nanomaterials exhibit enhanced mechanical properties at the nanoscale compared to composite materials, enabling superior strength, flexibility, and durability through nanoscale interactions studied in nanomechanics.

Load transfer mechanisms

Nanomaterials exhibit superior load transfer efficiency due to their high surface area-to-volume ratio enabling stronger interfacial bonding, while composite materials rely on matrix-fiber interactions for load distribution.

Hierarchical structures

Nanomaterials exhibit enhanced mechanical and functional properties through precisely engineered hierarchical structures, whereas composite materials achieve improved performance by integrating distinct hierarchical phases to optimize strength, toughness, and multifunctionality.

Tailored microstructures

Tailored microstructures in nanomaterials enable enhanced mechanical, thermal, and electrical properties compared to composite materials by precisely controlling particle size, distribution, and interface characteristics.

Multi-scale modeling

Multi-scale modeling integrates atomic-level simulations of nanomaterials with macroscopic behavior analyses of composite materials to predict multifunctional properties and optimize performance across different length scales.

Nanomaterials vs Composite materials Infographic

njnir.com

njnir.com