Shape memory alloys exhibit unique properties such as superelasticity and the ability to return to a predetermined shape after deformation, making them ideal for applications requiring large, reversible deformations. Piezoelectric materials generate electric charge in response to mechanical stress and are highly effective for precise actuation and sensing in micro-scale devices. Both materials offer distinct advantages, with shape memory alloys excelling in adaptability and durability, while piezoelectrics provide rapid response and high sensitivity in mechanical engineering applications.

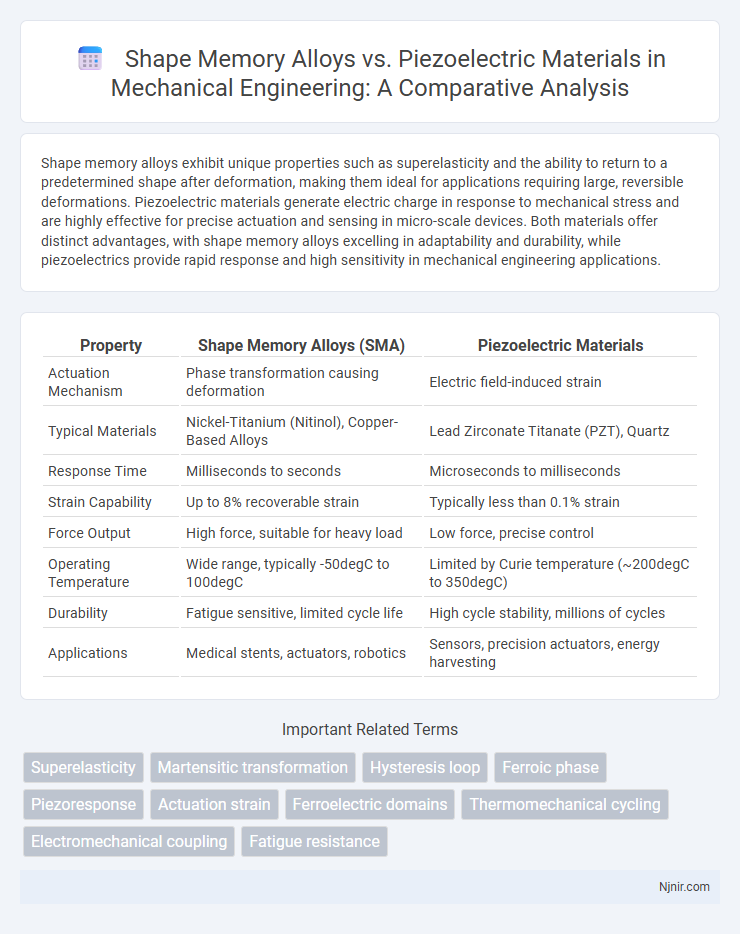

Table of Comparison

| Property | Shape Memory Alloys (SMA) | Piezoelectric Materials |

|---|---|---|

| Actuation Mechanism | Phase transformation causing deformation | Electric field-induced strain |

| Typical Materials | Nickel-Titanium (Nitinol), Copper-Based Alloys | Lead Zirconate Titanate (PZT), Quartz |

| Response Time | Milliseconds to seconds | Microseconds to milliseconds |

| Strain Capability | Up to 8% recoverable strain | Typically less than 0.1% strain |

| Force Output | High force, suitable for heavy load | Low force, precise control |

| Operating Temperature | Wide range, typically -50degC to 100degC | Limited by Curie temperature (~200degC to 350degC) |

| Durability | Fatigue sensitive, limited cycle life | High cycle stability, millions of cycles |

| Applications | Medical stents, actuators, robotics | Sensors, precision actuators, energy harvesting |

Introduction to Shape Memory Alloys and Piezoelectric Materials

Shape memory alloys (SMAs) exhibit unique properties such as superelasticity and the ability to return to a pre-deformed shape when heated, making them valuable for actuators and sensors. Piezoelectric materials generate electric charge in response to mechanical stress and conversely deform when subjected to an electric field, widely used in precision actuators and energy harvesting. The fundamental difference lies in SMAs relying on phase transformations for actuation, while piezoelectric materials operate through electric-mechanical coupling at the crystal lattice level.

Fundamental Working Principles

Shape memory alloys operate based on a reversible phase transformation between martensite and austenite phases, enabling them to return to a pre-deformed shape upon heating. Piezoelectric materials generate an electric charge in response to mechanical stress due to the displacement of ions within their crystal lattice structure. Both materials convert energy forms--thermal to mechanical for shape memory alloys and mechanical to electrical for piezoelectrics--making them essential in actuation and sensing applications.

Material Properties Comparison

Shape memory alloys exhibit exceptional elasticity and high damping capacity with the ability to recover large strains up to 8-10%, making them ideal for applications requiring reversible deformation and actuation. Piezoelectric materials, on the other hand, offer rapid response times and precise control with strain levels typically below 0.1%, driven by their electric field-induced polarization changes. The mechanical fatigue resistance of shape memory alloys surpasses many piezoelectric ceramics, while piezoelectrics excel in voltage sensitivity and frequency range, influencing their performance in sensors and actuators.

Actuation Mechanisms Explained

Shape memory alloys (SMAs) actuate through a solid-state phase transformation between martensite and austenite phases, enabling them to recover pre-defined shapes upon heating. In contrast, piezoelectric materials rely on the direct conversion of electrical energy into mechanical strain via electric dipole realignment within their crystalline structure. SMA actuation typically involves slower thermal cycles with high force output, whereas piezoelectric actuation achieves rapid, precise displacements but generally with lower force generation.

Response Time and Frequency Characteristics

Shape memory alloys exhibit slower response times typically in the range of milliseconds to seconds due to their thermally activated phase transformations, which limits their practical operating frequencies to low Hz ranges. In contrast, piezoelectric materials demonstrate ultra-fast response times in microseconds or less, enabling them to operate effectively at very high frequencies, often up to MHz or GHz. This makes piezoelectric materials highly suitable for applications requiring rapid actuation and high-frequency performance, while shape memory alloys are more appropriate for slower, larger-stroke actuation tasks.

Energy Efficiency and Power Consumption

Shape memory alloys exhibit higher energy efficiency in mechanical actuation due to their ability to undergo large deformations with minimal energy loss, primarily through thermal phase transformations. Piezoelectric materials consume less power during operation, converting electrical energy directly into mechanical strain with rapid response times, making them ideal for low-power precision applications. Energy efficiency in shape memory alloys often depends on thermal management, whereas piezoelectric materials excel in low consumption but limited strain output.

Durability and Fatigue Resistance

Shape memory alloys (SMAs) exhibit superior fatigue resistance due to their ability to undergo numerous phase transformations without permanent deformation, making them highly durable in cyclic applications. In contrast, piezoelectric materials often face limitations in durability because repeated mechanical and electrical loading can lead to micro-cracking and depolarization over time. The intrinsic mechanical flexibility of SMAs generally results in longer service life compared to brittle piezoelectric ceramics, which are prone to fatigue-induced degradation.

Common Applications in Mechanical Engineering

Shape memory alloys are widely used in actuators, adaptive structures, and vibration dampers due to their ability to undergo large strains and recover their original shape when heated. Piezoelectric materials find common applications in precision sensors, ultrasonic transducers, and energy harvesting devices because of their capability to convert mechanical stress into electrical charge and vice versa. Both materials are integral in robotics, aerospace, and automotive industries for enhancing performance through smart and responsive components.

Challenges and Limitations

Shape memory alloys (SMAs) face challenges such as slow response times, limited fatigue life, and significant hysteresis during phase transformations, which reduce their precision and durability in applications. Piezoelectric materials exhibit limitations including low strain amplitude, brittleness, and sensitivity to depolarization under high electric fields or elevated temperatures, restricting their operational range. Both materials require careful consideration of environmental conditions and mechanical stresses to optimize performance and reliability in smart actuator and sensor systems.

Future Research and Development Trends

Future research in shape memory alloys (SMAs) emphasizes enhancing fatigue life, developing high-temperature variants, and improving response speed for aerospace and biomedical applications. Piezoelectric materials are advancing through the exploration of lead-free alternatives, nanoscale engineering, and integration into flexible electronics to boost energy harvesting efficiency. Both fields are converging towards hybrid systems combining the adaptive properties of SMAs with the precise actuation capabilities of piezoelectrics for next-generation smart devices.

Superelasticity

Shape memory alloys exhibit superior superelasticity with large reversible strains up to 8%, outperforming piezoelectric materials which typically offer strains below 0.2%.

Martensitic transformation

Shape memory alloys exhibit Martensitic transformation enabling reversible phase changes for shape recovery, whereas piezoelectric materials rely on electric polarization without phase transformation.

Hysteresis loop

Shape memory alloys exhibit larger, nonlinear hysteresis loops due to phase transformations, while piezoelectric materials show smaller, more linear hysteresis loops associated with electric field-induced strain.

Ferroic phase

Ferroic phase transitions in shape memory alloys involve reversible martensitic transformations enabling large strain recovery, while piezoelectric materials exhibit ferroic properties through polarization switching in their crystal lattice for precise electromechanical coupling.

Piezoresponse

Shape memory alloys exhibit mechanical shape recovery through temperature-induced phase transformations while piezoelectric materials generate electric charge in response to applied mechanical stress, with piezoresponse specifically reflecting the electromechanical coupling efficiency in piezoelectric materials.

Actuation strain

Shape memory alloys exhibit larger actuation strain up to 8%, whereas piezoelectric materials typically provide much smaller strains around 0.1% but offer faster response times and higher precision in actuation.

Ferroelectric domains

Ferroelectric domains in piezoelectric materials enable reversible electric polarization under mechanical stress, offering faster response times and higher precision compared to the thermally-driven phase transformations in shape memory alloys.

Thermomechanical cycling

Shape memory alloys exhibit superior durability and stable thermomechanical cycling performance compared to piezoelectric materials, which often suffer from fatigue and depolarization under repeated thermal and mechanical stress.

Electromechanical coupling

Shape memory alloys exhibit lower electromechanical coupling efficiency compared to piezoelectric materials, which provide superior precision and responsiveness in converting electrical energy into mechanical deformation.

Fatigue resistance

Shape memory alloys exhibit superior fatigue resistance compared to piezoelectric materials, making them more durable for cyclic mechanical applications.

shape memory alloys vs piezoelectric materials Infographic

njnir.com

njnir.com