Axial flow pumps deliver high flow rates with low pressure, making them ideal for applications like irrigation and flood control where large volumes of fluid need to be moved efficiently. Radial flow pumps generate higher pressures at lower flow rates, suitable for tasks requiring significant head such as water supply systems and boiler feed pumps. Choosing between axial and radial flow pumps depends on balancing flow rate and pressure requirements specific to mechanical engineering applications.

Table of Comparison

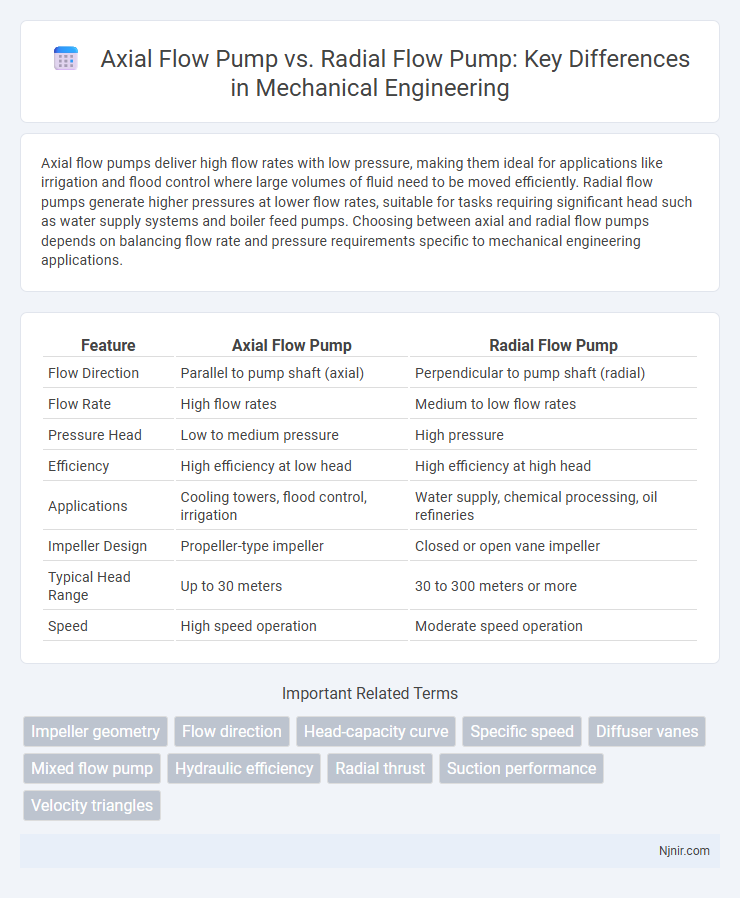

| Feature | Axial Flow Pump | Radial Flow Pump |

|---|---|---|

| Flow Direction | Parallel to pump shaft (axial) | Perpendicular to pump shaft (radial) |

| Flow Rate | High flow rates | Medium to low flow rates |

| Pressure Head | Low to medium pressure | High pressure |

| Efficiency | High efficiency at low head | High efficiency at high head |

| Applications | Cooling towers, flood control, irrigation | Water supply, chemical processing, oil refineries |

| Impeller Design | Propeller-type impeller | Closed or open vane impeller |

| Typical Head Range | Up to 30 meters | 30 to 300 meters or more |

| Speed | High speed operation | Moderate speed operation |

Introduction to Axial and Radial Flow Pumps

Axial flow pumps move fluid parallel to the pump shaft, generating high flow rates with low pressure, making them suitable for applications like flood control and circulation systems. Radial flow pumps, also known as centrifugal pumps, direct fluid perpendicular to the shaft, producing higher pressure at lower flow rates, ideal for water supply and industrial processes. Both pump types use impellers but differ in flow direction and hydraulic performance, influencing their selection based on required head and flow characteristics.

Fundamental Working Principles

Axial flow pumps move fluid parallel to the pump shaft using an impeller with blades shaped like airplane propellers, generating high flow rates with low pressure. Radial flow pumps direct fluid perpendicular to the shaft by imparting kinetic energy through a rotating impeller, converting velocity into pressure and producing higher pressures at lower flow rates. The fundamental difference lies in flow direction and energy conversion: axial pumps prioritize flow volume, while radial pumps emphasize pressure development.

Design and Construction Differences

Axial flow pumps feature impellers with blades oriented parallel to the pump shaft, allowing fluid to move primarily along the axis, resulting in high flow rates with low pressure. Radial flow pumps have impellers with blades arranged perpendicular to the shaft, directing fluid outward from the center to the periphery, generating higher pressure but lower flow compared to axial pumps. The structural design of axial pumps includes longer, slim impellers for streamlined flow, while radial pumps utilize compact, volute casings to support the radial discharge and pressure build-up.

Flow Characteristics and Patterns

Axial flow pumps generate high flow rates with low pressure by moving fluid parallel to the pump shaft, exhibiting a linear flow pattern ideal for applications requiring large volumes at low head. Radial flow pumps, or centrifugal pumps, impart energy through radial movement away from the shaft, creating higher pressure with lower flow rates and a spiral flow pattern suited for high-head, low-flow scenarios. The distinct flow characteristics of axial flow pumps enable efficient handling of large water volumes, while radial flow pumps excel in systems demanding significant pressure increases.

Head and Discharge Comparisons

Axial flow pumps generate low head but provide high discharge rates, making them ideal for applications requiring large volumes of fluid at low pressure. Radial flow pumps, on the other hand, produce higher head with moderate discharge, suited for systems needing significant pressure increase. The key distinction lies in axial flow pumps' propeller-like impeller promoting linear fluid movement versus radial flow pumps' centrifugal impellers enhancing pressure through fluid velocity conversion.

Applications in Mechanical Engineering

Axial flow pumps are primarily utilized in applications requiring high flow rates with low to medium pressure, such as irrigation, flood control, and circulating water systems in power plants. Radial flow pumps excel in delivering high-pressure outputs at lower flow rates, making them suitable for boiler feedwater, chemical processing, and HVAC systems in mechanical engineering. Selecting between axial and radial flow pumps depends on the specific hydraulic requirements, efficiency, and system design constraints of the application.

Efficiency and Performance Analysis

Axial flow pumps deliver high flow rates at low pressure and are highly efficient for applications requiring large volumes of fluid movement, such as irrigation and flood control. Radial flow pumps, or centrifugal pumps, excel in generating higher pressure at moderate flow rates, making them suitable for water supply and industrial processes with greater head requirements. Efficiency analysis shows axial flow pumps perform best at low head and high flow, while radial flow pumps maintain efficiency across a wider range of head and flow conditions due to their design differences.

Advantages of Axial Flow Pumps

Axial flow pumps offer superior efficiency in handling high flow rates at low pressure heads, making them ideal for applications like irrigation, flood control, and circulating large water volumes. They provide a more uniform flow with lower energy consumption compared to radial flow pumps, which are better suited for high-pressure, low-flow situations. The axial flow design also results in smaller pump size and lighter weight for the same capacity, reducing installation and maintenance costs.

Advantages of Radial Flow Pumps

Radial flow pumps offer superior pressure generation compared to axial flow pumps, making them ideal for applications requiring high head and moderate flow rates. These pumps provide enhanced efficiency in handling viscous fluids and maintain stable performance under varying operational conditions. Their robust design ensures reliability and longevity in industrial applications such as water supply, chemical processing, and wastewater treatment.

Selection Criteria for Industrial Use

Axial flow pumps are ideal for applications requiring high flow rates with low to moderate pressure, such as irrigation and flood control, due to their impellers that push fluid parallel to the pump shaft. Radial flow pumps, or centrifugal pumps, are better suited for high-pressure applications like water supply and chemical processing because their impellers direct fluid perpendicular to the shaft, generating greater head. Selection criteria for industrial use prioritize flow rate, pressure requirements, fluid viscosity, and site-specific conditions to optimize pump performance and energy efficiency.

Impeller geometry

Axial flow pumps feature impellers with flat or slightly curved blades that move fluid parallel to the pump shaft, while radial flow pumps have impellers with backward-curved blades that direct fluid perpendicularly to the shaft, optimizing flow direction and pressure.

Flow direction

Axial flow pumps direct fluid parallel to the pump shaft for high flow rates with low pressure, while radial flow pumps move fluid perpendicular to the shaft, generating higher pressure at lower flow rates.

Head-capacity curve

Axial flow pumps maintain a nearly constant head with increasing capacity, while radial flow pumps experience a significant decrease in head as capacity rises.

Specific speed

Axial flow pumps have high specific speeds typically above 1000, making them ideal for high flow and low head applications, whereas radial flow pumps have lower specific speeds, generally between 50 and 1000, suited for moderate flow and medium to high head requirements.

Diffuser vanes

Axial flow pumps use diffuser vanes to gradually convert kinetic energy into pressure by slowing axial flow, whereas radial flow pumps rely on volute casings or diffuser vanes to efficiently guide radial flow and enhance pressure rise.

Mixed flow pump

Mixed flow pumps combine axial and radial flow characteristics, offering higher head than axial flow pumps and greater flow capacity than radial flow pumps, making them ideal for medium head and flow applications.

Hydraulic efficiency

Axial flow pumps typically achieve higher hydraulic efficiency at low to medium head applications, while radial flow pumps deliver better efficiency at high head, low flow conditions.

Radial thrust

Radial flow pumps generate lower radial thrust compared to axial flow pumps, resulting in improved bearing life and reduced maintenance costs.

Suction performance

Axial flow pumps offer superior suction performance with low NPSH requirements due to their high flow, low-pressure design compared to radial flow pumps, which handle higher pressures but have higher NPSH needs.

Velocity triangles

Axial flow pumps feature velocity triangles with flow direction parallel to the impeller axis, optimizing high flow rates and low pressure rises, whereas radial flow pumps have velocity triangles indicating flow perpendicular to the shaft, suited for higher pressure heads and lower flow rates.

Axial flow pump vs radial flow pump Infographic

njnir.com

njnir.com