Kinematic viscosity measures a fluid's resistance to flow under gravity and is expressed as the ratio of dynamic viscosity to fluid density. Dynamic viscosity quantifies a fluid's internal resistance to shear or flow when an external force is applied, expressed in pascal-seconds (Pa*s). Understanding the distinction between these viscosities is crucial for designing and analyzing fluid flow systems in mechanical engineering applications.

Table of Comparison

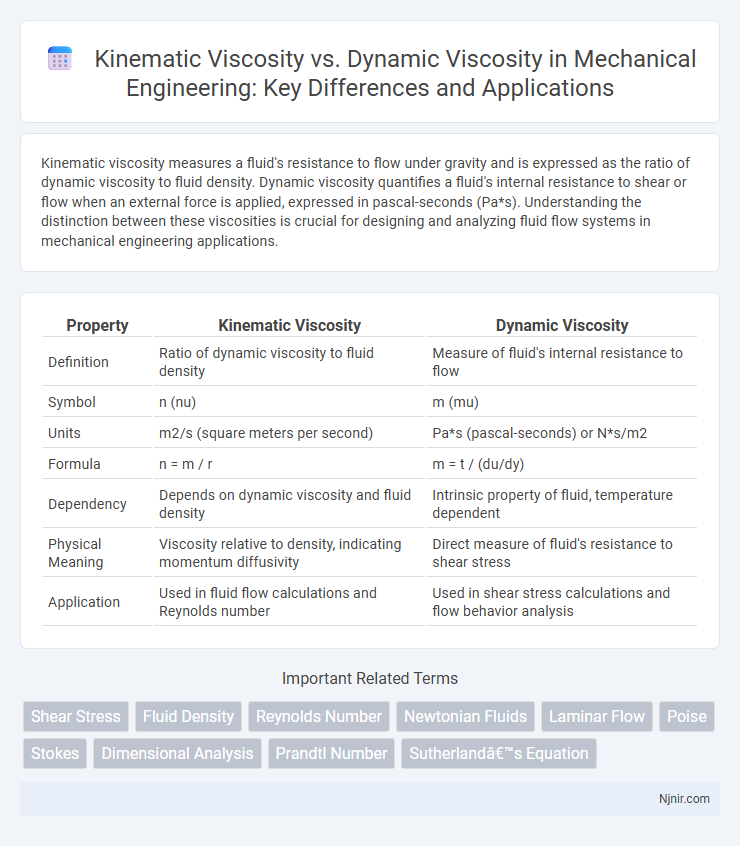

| Property | Kinematic Viscosity | Dynamic Viscosity |

|---|---|---|

| Definition | Ratio of dynamic viscosity to fluid density | Measure of fluid's internal resistance to flow |

| Symbol | n (nu) | m (mu) |

| Units | m2/s (square meters per second) | Pa*s (pascal-seconds) or N*s/m2 |

| Formula | n = m / r | m = t / (du/dy) |

| Dependency | Depends on dynamic viscosity and fluid density | Intrinsic property of fluid, temperature dependent |

| Physical Meaning | Viscosity relative to density, indicating momentum diffusivity | Direct measure of fluid's resistance to shear stress |

| Application | Used in fluid flow calculations and Reynolds number | Used in shear stress calculations and flow behavior analysis |

Introduction to Viscosity in Mechanical Engineering

Kinematic viscosity and dynamic viscosity are critical properties in mechanical engineering that describe a fluid's resistance to flow and deformation. Dynamic viscosity measures the internal friction between fluid layers under shear stress, expressed in pascal-seconds (Pa*s), while kinematic viscosity is the ratio of dynamic viscosity to fluid density, measured in square meters per second (m2/s). Understanding both viscosities is essential for modeling fluid behavior in applications such as lubrication, hydraulic systems, and heat transfer analysis.

Defining Kinematic Viscosity

Kinematic viscosity measures a fluid's resistance to flow under gravity, defined as the ratio of dynamic viscosity to fluid density, typically expressed in stokes (St) or square meters per second (m2/s). Unlike dynamic viscosity, which quantifies internal friction forces in pascal-seconds (Pa*s), kinematic viscosity accounts for fluid density, making it crucial in applications involving fluid flow and heat transfer. Precise evaluation of kinematic viscosity is essential in industries such as petrochemicals, lubrication, and hydraulics for optimizing system performance and ensuring accurate fluid dynamics modeling.

Understanding Dynamic Viscosity

Dynamic viscosity measures a fluid's internal resistance to flow under applied stress, expressed in pascal-seconds (Pa*s), representing the force needed to move adjacent fluid layers. It quantifies how molecules within the fluid interact and resist deformation during shear. Understanding dynamic viscosity is crucial for analyzing fluid behavior in engineering applications, such as lubrication, fluid transport, and aerodynamic design, where resistance to flow impacts system performance.

Fundamental Differences Between Kinematic and Dynamic Viscosity

Kinematic viscosity measures a fluid's resistance to flow under the influence of gravity and is expressed in square meters per second (m2/s), while dynamic viscosity quantifies the internal friction between fluid layers and is measured in pascal-seconds (Pa*s). The fundamental difference lies in kinematic viscosity being the ratio of dynamic viscosity to fluid density, linking flow behavior to fluid mass per volume. This distinction is crucial in fluid mechanics, where dynamic viscosity addresses shear stress, and kinematic viscosity relates to flow velocity profiles and Reynolds number calculations.

Units and Measurement Methods

Kinematic viscosity is measured in square meters per second (m2/s) and is determined by dividing dynamic viscosity by fluid density, quantifying a fluid's resistance to flow under gravitational forces. Dynamic viscosity, expressed in pascal-seconds (Pa*s) or poise (P), is measured using viscometers such as rotational or capillary types, representing the internal friction within a fluid. Precise measurement methods for dynamic viscosity include the use of rheometers, while kinematic viscosity is often assessed with bubble viscometers or flow cups that calculate flow time through a calibrated tube.

Role in Fluid Mechanics and Hydrodynamics

Kinematic viscosity quantifies a fluid's resistance to flow under gravity by relating dynamic viscosity to fluid density, playing a critical role in characterizing flow behavior in open channels and natural waterways. Dynamic viscosity measures a fluid's internal resistance to shear stress, essential for calculating shear forces in pipe flow, lubrication, and turbulent flow modeling. Both viscosities are fundamental in hydrodynamics for predicting boundary layer development, flow separation, and energy dissipation in fluid systems.

Applications in Mechanical Engineering Systems

Kinematic viscosity is crucial in analyzing fluid flow in mechanical engineering systems where density effects influence lubrication and cooling processes, such as in hydraulic systems and bearing designs. Dynamic viscosity is essential for determining shear stress and resistance in applications like gearbox oils and engine lubricants, ensuring efficient power transmission and reducing wear. Both viscosities are applied to optimize fluid performance, thermal management, and energy efficiency in pumps, turbines, and heat exchangers.

Factors Influencing Kinematic and Dynamic Viscosity

Temperature significantly influences both kinematic and dynamic viscosity, with higher temperatures generally decreasing viscosity by reducing intermolecular forces in fluids. Pressure impacts dynamic viscosity more prominently, especially in liquids where increased pressure leads to higher viscosity, while kinematic viscosity also varies as it depends on fluid density. Fluid composition and molecular structure play crucial roles, as complex molecules or suspensions increase both viscosities, affecting flow and resistance characteristics in engineering and scientific applications.

Importance in Lubrication and Thermal Analysis

Kinematic viscosity, measuring fluid flow under gravity, influences lubricant film formation and stability, directly affecting machinery performance and wear protection. Dynamic viscosity determines resistance to shear stress, critical for analyzing heat generation and dissipation in tribological contacts during lubrication. Accurate assessment of both viscosities allows optimal lubricant selection, enhancing thermal management and maintaining mechanical efficiency.

Summary: Choosing the Right Viscosity Parameter

Kinematic viscosity measures a fluid's resistance to flow under gravity, expressed in stokes (St), while dynamic viscosity quantifies internal friction during flow, measured in pascal-seconds (Pa*s). Selecting kinematic viscosity suits applications involving gravitational flow or laminar conditions, whereas dynamic viscosity is critical for processes with applied shear forces or complex flow dynamics. Engineers must evaluate fluid behavior, operational conditions, and measurement convenience to determine the appropriate viscosity parameter.

Shear Stress

Dynamic viscosity measures a fluid's resistance to shear stress, while kinematic viscosity relates this resistance to fluid density, defining the fluid's internal flow under applied shear stress.

Fluid Density

Kinematic viscosity measures a fluid's resistance to flow divided by its density, while dynamic viscosity directly quantifies the fluid's internal resistance regardless of density.

Reynolds Number

Reynolds Number is calculated using dynamic viscosity, which accounts for fluid force per unit area, while kinematic viscosity divides dynamic viscosity by fluid density to describe flow characteristics and predict turbulence onset.

Newtonian Fluids

Kinematic viscosity of Newtonian fluids is the ratio of dynamic viscosity to fluid density, indicating the fluid's internal resistance to flow relative to its mass.

Laminar Flow

Kinematic viscosity, defined as dynamic viscosity divided by fluid density, determines the laminar flow regime by influencing Reynolds number thresholds.

Poise

Dynamic viscosity is measured in Poise (P), representing the fluid's internal resistance to flow, while kinematic viscosity, expressed in Stokes (St), is the dynamic viscosity divided by the fluid's density.

Stokes

Stokes' law relates dynamic viscosity to kinematic viscosity by defining viscous drag on spherical particles moving through a fluid, where dynamic viscosity equals kinematic viscosity multiplied by fluid density.

Dimensional Analysis

Kinematic viscosity (n) equals dynamic viscosity (m) divided by fluid density (r), expressed dimensionally as [L^2 T^-1] = [M L^-1 T^-1] / [M L^-3], highlighting the fundamental relationship through dimensional analysis.

Prandtl Number

Prandtl Number, defined as the ratio of kinematic viscosity to thermal diffusivity, characterizes the relative thickness of momentum and thermal boundary layers in fluid flow and depends directly on dynamic viscosity divided by fluid density.

Sutherland’s Equation

Sutherland's Equation models dynamic viscosity of gases as a function of temperature, enabling calculation of kinematic viscosity by dividing dynamic viscosity by fluid density at specific conditions.

kinematic viscosity vs dynamic viscosity Infographic

njnir.com

njnir.com