Pneumatic actuators offer faster response times and cleaner operation using compressed air, making them ideal for applications requiring speed and minimal maintenance. Hydraulic actuators provide higher force and precise control through incompressible fluid, suited for heavy-duty tasks and high-load environments. Choosing between pneumatic and hydraulic actuators depends on factors like force requirements, speed, environmental conditions, and system complexity.

Table of Comparison

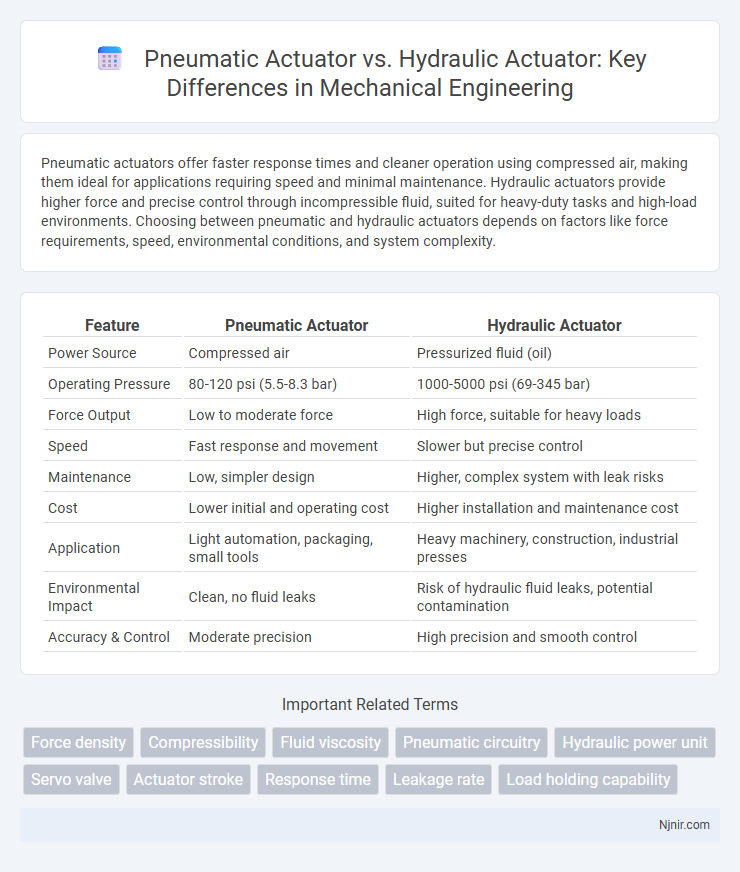

| Feature | Pneumatic Actuator | Hydraulic Actuator |

|---|---|---|

| Power Source | Compressed air | Pressurized fluid (oil) |

| Operating Pressure | 80-120 psi (5.5-8.3 bar) | 1000-5000 psi (69-345 bar) |

| Force Output | Low to moderate force | High force, suitable for heavy loads |

| Speed | Fast response and movement | Slower but precise control |

| Maintenance | Low, simpler design | Higher, complex system with leak risks |

| Cost | Lower initial and operating cost | Higher installation and maintenance cost |

| Application | Light automation, packaging, small tools | Heavy machinery, construction, industrial presses |

| Environmental Impact | Clean, no fluid leaks | Risk of hydraulic fluid leaks, potential contamination |

| Accuracy & Control | Moderate precision | High precision and smooth control |

Introduction to Pneumatic and Hydraulic Actuators

Pneumatic actuators use compressed air to create motion, offering quick response and clean operation ideal for automation in industries such as packaging and material handling. Hydraulic actuators utilize pressurized fluids to generate high force and precise control, commonly employed in heavy machinery like construction equipment and manufacturing presses. Both types convert energy into mechanical movement but differ in power source, force output, and application suitability.

Fundamental Operating Principles

Pneumatic actuators utilize compressed air to generate linear or rotary motion, relying on the expansion and contraction of air pressure within a cylinder. Hydraulic actuators operate by using incompressible fluid under pressure, providing greater force and precise control through fluid displacement. The fundamental difference lies in the medium used--gas for pneumatic and liquid for hydraulic--resulting in varied performance characteristics such as speed, force, and responsiveness.

Key Components Comparison

Pneumatic actuators utilize compressed air as the power source, featuring key components such as cylinders, pistons, valves, and air compressors, which provide rapid response and clean operation. Hydraulic actuators rely on pressurized fluid, incorporating components like hydraulic pumps, fluid reservoirs, cylinders, and control valves, enabling higher force output and precise control in heavy-duty applications. The choice between pneumatic and hydraulic actuators depends on factors including required force, speed, and environmental considerations.

Pressure and Force Capabilities

Pneumatic actuators operate using compressed air typically between 80 to 120 psi, providing moderate force suitable for lightweight or medium-duty applications. Hydraulic actuators utilize pressurized fluids delivering significantly higher force, often exceeding 3,000 psi, making them ideal for heavy-duty industrial operations requiring strong, precise movement. The choice between pneumatic and hydraulic actuators depends on the pressure and force demands, with hydraulics offering superior force capabilities at higher pressures.

Response Time and Precision

Pneumatic actuators typically offer faster response times due to the compressibility of air and lightweight components, making them ideal for applications requiring quick, repetitive motions. Hydraulic actuators provide higher precision and smoother control because of the incompressible nature of hydraulic fluid, enabling excellent force modulation in heavy-duty tasks. Response time in pneumatic systems averages milliseconds, whereas hydraulic systems prioritize precision with response times often ranging from milliseconds to seconds depending on load and valve design.

Energy Efficiency and Operational Costs

Pneumatic actuators offer higher energy efficiency in applications requiring rapid and repetitive motion due to their lower air consumption and simpler maintenance compared to hydraulic actuators. Hydraulic actuators tend to have higher operational costs because of energy losses from fluid friction and the need for complex fluid handling systems, including pumps and reservoirs. Optimizing system design and application specifics is crucial to balancing initial investment and long-term energy expenses between pneumatic and hydraulic actuator technologies.

Maintenance Requirements and Longevity

Pneumatic actuators require less maintenance due to fewer moving parts and the use of compressed air, which reduces contamination and wear, extending their operational lifespan. Hydraulic actuators demand more frequent maintenance to manage potential leaks, fluid contamination, and seal replacements, which can shorten their durability if neglected. The longevity of pneumatic actuators typically surpasses hydraulic systems in environments where cleanliness and simpler maintenance routines are prioritized.

Application Suitability in Mechanical Engineering

Pneumatic actuators provide rapid, clean, and low-cost motion control, making them ideal for applications requiring high speed and moderate force, such as packaging machinery and automation systems. Hydraulic actuators offer superior force and precise control in heavy-duty environments, fitting applications like construction equipment, presses, and heavy machinery where high load capacity is critical. Mechanical engineering decisions often hinge on factors like force requirements, environmental conditions, and system complexity to select between pneumatic and hydraulic actuators for optimal application suitability.

Safety Considerations and Risk Factors

Pneumatic actuators offer enhanced safety in hazardous environments due to their use of compressed air, which reduces the risk of fluid leaks and fire hazards compared to hydraulic actuators operating under high-pressure oil. Hydraulic actuators pose higher risks of leaks causing slippery surfaces, environmental contamination, and potential accidents from high-pressure fluid injection. Proper maintenance and monitoring are critical for hydraulic systems to mitigate risks, whereas pneumatic systems require regular inspection of air supply quality to ensure operational safety.

Future Trends and Technological Advancements

Future trends in pneumatic actuators emphasize energy efficiency improvements and integration with smart IoT systems for predictive maintenance, enhancing operational reliability. Hydraulic actuators are advancing with the development of eco-friendly biodegradable fluids and compact, high-force designs to meet stringent environmental and space constraints. Both actuator types increasingly incorporate AI-driven control algorithms to optimize performance and reduce downtime in industrial automation.

Force density

Hydraulic actuators exhibit higher force density than pneumatic actuators due to the incompressibility of hydraulic fluid, enabling greater force output in a compact design.

Compressibility

Pneumatic actuators utilize compressible air, resulting in faster response and cushioning effects, whereas hydraulic actuators use incompressible fluids, providing higher force accuracy and consistent motion control.

Fluid viscosity

Pneumatic actuators use compressed air with low viscosity, enabling faster response and cleaner operation, while hydraulic actuators rely on high-viscosity fluids like oil, providing greater force and precision but slower movement.

Pneumatic circuitry

Pneumatic actuators, powered by compressed air, offer faster response times and simpler pneumatic circuitry design compared to hydraulic actuators, making them ideal for lightweight applications requiring clean and safe operation.

Hydraulic power unit

A hydraulic power unit in hydraulic actuators delivers high force and precise control through pressurized fluid, making it more suitable than pneumatic actuators for heavy-duty industrial applications requiring consistent power and smooth operation.

Servo valve

Servo valves in hydraulic actuators provide precise control and high force output, while pneumatic actuators offer faster response and cleaner operation but with lower accuracy and force.

Actuator stroke

Pneumatic actuators typically offer shorter actuator strokes up to 12 inches, while hydraulic actuators provide longer stroke capabilities exceeding several feet for heavy-duty industrial applications.

Response time

Pneumatic actuators typically offer faster response times than hydraulic actuators due to lower fluid viscosity and quicker air compression dynamics.

Leakage rate

Pneumatic actuators typically have lower leakage rates than hydraulic actuators due to the compressibility of air reducing seal wear and maintenance requirements.

Load holding capability

Hydraulic actuators provide superior load holding capability compared to pneumatic actuators due to their incompressible fluid medium, enabling precise control and sustained force under load.

Pneumatic actuator vs hydraulic actuator Infographic

njnir.com

njnir.com