Regenerative braking recovers kinetic energy by converting it into electrical energy, improving overall energy efficiency and reducing wear on brake components. Friction braking relies on mechanical pads pressing against rotors to generate heat and slow the vehicle, resulting in higher energy loss and more frequent maintenance. Combining both systems enhances vehicle performance by optimizing energy conservation and ensuring reliable stopping power.

Table of Comparison

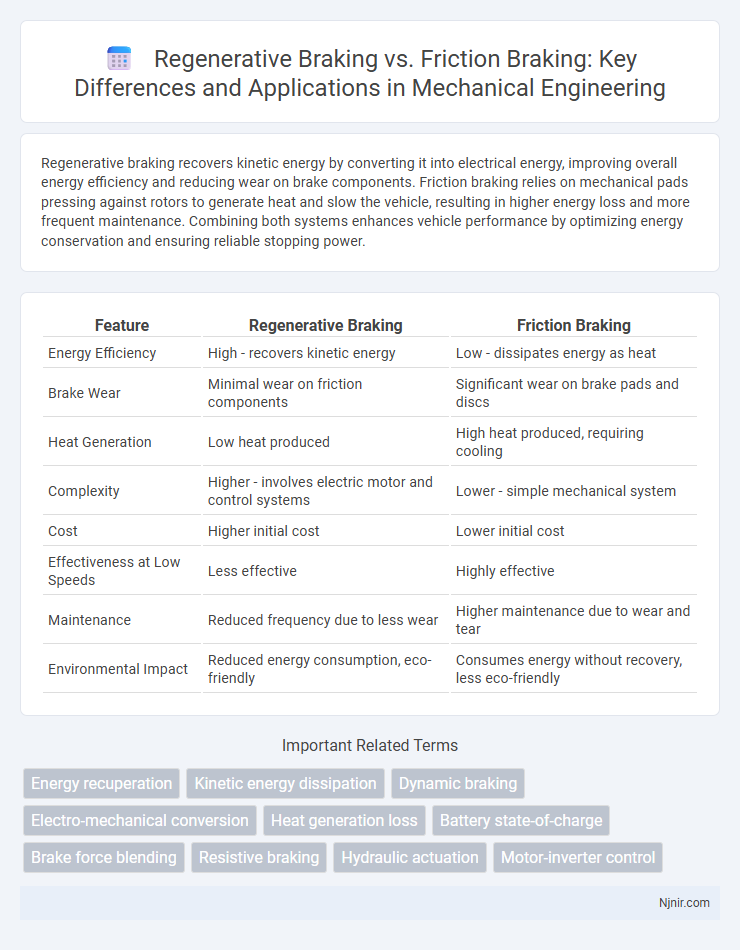

| Feature | Regenerative Braking | Friction Braking |

|---|---|---|

| Energy Efficiency | High - recovers kinetic energy | Low - dissipates energy as heat |

| Brake Wear | Minimal wear on friction components | Significant wear on brake pads and discs |

| Heat Generation | Low heat produced | High heat produced, requiring cooling |

| Complexity | Higher - involves electric motor and control systems | Lower - simple mechanical system |

| Cost | Higher initial cost | Lower initial cost |

| Effectiveness at Low Speeds | Less effective | Highly effective |

| Maintenance | Reduced frequency due to less wear | Higher maintenance due to wear and tear |

| Environmental Impact | Reduced energy consumption, eco-friendly | Consumes energy without recovery, less eco-friendly |

Overview of Braking Systems in Mechanical Engineering

Regenerative braking systems convert kinetic energy into electrical energy during deceleration, improving energy efficiency and reducing wear on mechanical components. Friction braking relies on mechanical force applied through brake pads or shoes to slow a vehicle, dissipating kinetic energy as heat. Both systems are integral in mechanical engineering design, balancing energy recovery with reliable stopping power.

Fundamentals of Friction Braking

Friction braking relies on the conversion of kinetic energy into thermal energy through the contact of brake pads against a rotating surface, such as a disc or drum, creating resistance to slow or stop a vehicle. The effectiveness of friction brakes depends on factors like material composition, surface area, and heat dissipation to prevent fade and ensure consistent performance. Unlike regenerative braking that recovers energy, friction braking primarily dissipates energy as heat without energy recovery or storage.

Principles of Regenerative Braking

Regenerative braking recovers kinetic energy during deceleration by converting it into electrical energy stored in the battery, enhancing overall vehicle efficiency. Unlike friction braking, which dissipates energy as heat through brake pads and rotors, regenerative braking utilizes the electric motor as a generator. This principle reduces wear on mechanical brakes and improves energy conservation in electric and hybrid vehicles.

Key Mechanical Components in Both Systems

Regenerative braking systems primarily rely on electric motors, inverters, and battery packs to convert kinetic energy into electrical energy for storage, enhancing energy efficiency. Friction braking systems utilize mechanical components such as brake pads, rotors, calipers, and hydraulic cylinders to generate friction and dissipate kinetic energy as heat for vehicle deceleration. Understanding the distinct mechanical components highlights the energy recovery advantage in regenerative braking versus the wear-and-replace nature of friction braking parts.

Energy Efficiency: Regenerative vs. Friction Braking

Regenerative braking converts kinetic energy into electrical energy stored in the battery, significantly improving energy efficiency and reducing overall energy consumption in electric and hybrid vehicles. In contrast, friction braking dissipates kinetic energy as heat, resulting in energy loss and reduced fuel efficiency. The ability of regenerative braking to recapture energy during deceleration offers substantial improvements in vehicle range and environmental sustainability compared to traditional friction braking systems.

Impact on Vehicle Performance and Safety

Regenerative braking enhances vehicle performance by recovering kinetic energy and improving energy efficiency, which extends battery range in electric and hybrid vehicles. Friction braking provides consistent stopping power and reliability, crucial for emergency situations and low-speed control. Combining both systems optimizes safety and performance by balancing energy regeneration with effective and immediate braking response.

Maintenance Requirements and Longevity

Regenerative braking systems reduce wear on brake components by converting kinetic energy into electrical energy, significantly extending the lifespan of brake pads and discs compared to traditional friction braking. Friction braking relies on mechanical contact to slow vehicles, causing faster wear and more frequent maintenance due to heat and material abrasion. Maintenance requirements for regenerative brakes are lower, leading to reduced overall costs and longer intervals between brake servicing.

Environmental Implications and Emissions

Regenerative braking significantly reduces environmental impact by converting kinetic energy into electrical energy, decreasing overall fuel consumption and lowering greenhouse gas emissions compared to friction braking. Friction braking relies on mechanical friction, which not only wastes energy as heat but also produces brake dust, contributing to particulate matter pollution. Implementing regenerative braking systems in electric and hybrid vehicles leads to improved energy efficiency and reduced air pollution, supporting sustainable transportation goals.

Application Scenarios and Industry Adoption

Regenerative braking excels in electric and hybrid vehicles by converting kinetic energy into electrical energy, enhancing energy efficiency and extending battery life, making it ideal for urban driving with frequent stops. Friction braking remains dominant in traditional combustion engine vehicles and heavy-duty applications due to its reliability under high-speed and emergency conditions. Industry adoption sees automakers increasingly integrating regenerative braking in passenger EVs, while friction braking persists in commercial trucks and motorcycles for robust stopping power.

Future Trends in Braking Technologies

Future trends in braking technologies emphasize the integration of regenerative braking systems with advanced electronic controls to maximize energy recovery and enhance efficiency in electric and hybrid vehicles. Innovations in friction materials and smart brake-by-wire systems aim to improve safety, reduce maintenance, and support autonomous driving capabilities. Research into solid-state braking components and AI-enhanced sensors is driving the evolution toward more sustainable, precise, and adaptive braking solutions.

Energy recuperation

Regenerative braking recovers and stores kinetic energy as electrical energy during deceleration, significantly increasing energy efficiency compared to friction braking, which dissipates kinetic energy as heat without energy recapture.

Kinetic energy dissipation

Regenerative braking converts kinetic energy into electrical energy to recharge the battery, significantly reducing energy loss compared to friction braking, which dissipates kinetic energy as heat through brake pads.

Dynamic braking

Dynamic braking in regenerative systems converts kinetic energy into electrical energy to recharge batteries, whereas friction braking dissipates kinetic energy as heat through brake pads.

Electro-mechanical conversion

Regenerative braking converts kinetic energy into electrical energy through electro-mechanical conversion for battery storage, whereas friction braking dissipates kinetic energy as heat via mechanical friction.

Heat generation loss

Regenerative braking significantly reduces heat generation loss by converting kinetic energy into electrical energy, whereas friction braking dissipates energy as heat, causing higher thermal losses and reduced energy efficiency.

Battery state-of-charge

Regenerative braking increases battery state-of-charge by converting kinetic energy into electrical energy, while friction braking depletes energy without affecting battery charge.

Brake force blending

Brake force blending optimizes vehicle deceleration by seamlessly integrating regenerative braking to recover energy and friction braking to ensure safety and consistent stopping power.

Resistive braking

Resistive braking in regenerative systems converts kinetic energy into electrical energy stored in batteries, whereas friction braking dissipates kinetic energy as heat through brake pads and discs.

Hydraulic actuation

Hydraulic actuation in regenerative braking systems enhances energy efficiency by enabling seamless transition from friction braking, which primarily relies on mechanical force to dissipate energy as heat.

Motor-inverter control

Motor-inverter control in regenerative braking efficiently converts kinetic energy into electrical energy to recharge batteries, whereas friction braking relies on mechanical force to dissipate energy as heat without energy recovery.

Regenerative braking vs Friction braking Infographic

njnir.com

njnir.com