Parametric modeling enables engineers to create and modify designs through predefined parameters and constraints, ensuring accuracy and easy updates during the design process. Direct modeling offers greater flexibility by allowing intuitive, real-time modifications without the need for a history tree or predefined constraints, ideal for conceptual design and rapid prototyping. Choosing between parametric and direct modeling depends on project requirements, with parametric suited for complex, detail-driven engineering tasks and direct modeling preferred for quick edits and iterative development.

Table of Comparison

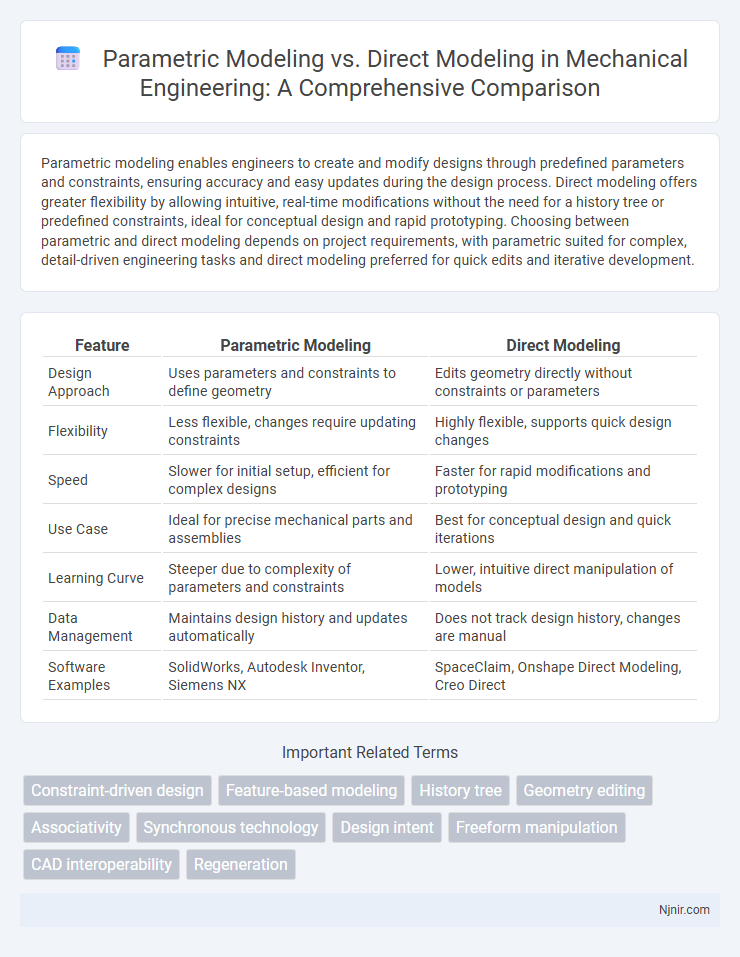

| Feature | Parametric Modeling | Direct Modeling |

|---|---|---|

| Design Approach | Uses parameters and constraints to define geometry | Edits geometry directly without constraints or parameters |

| Flexibility | Less flexible, changes require updating constraints | Highly flexible, supports quick design changes |

| Speed | Slower for initial setup, efficient for complex designs | Faster for rapid modifications and prototyping |

| Use Case | Ideal for precise mechanical parts and assemblies | Best for conceptual design and quick iterations |

| Learning Curve | Steeper due to complexity of parameters and constraints | Lower, intuitive direct manipulation of models |

| Data Management | Maintains design history and updates automatically | Does not track design history, changes are manual |

| Software Examples | SolidWorks, Autodesk Inventor, Siemens NX | SpaceClaim, Onshape Direct Modeling, Creo Direct |

Introduction to Parametric and Direct Modeling

Parametric modeling uses parameters and constraints to define and control geometry, enabling easy modification and design intent preservation, often applied in CAD software like SolidWorks and Autodesk Inventor. Direct modeling allows intuitive manipulation of geometry without maintaining a history tree, offering flexibility and faster changes, especially useful in conceptual design and reverse engineering. Both approaches serve different purposes in product development, with parametric modeling emphasizing precision and control, while direct modeling prioritizes speed and simplicity.

Fundamental Concepts of Parametric Modeling

Parametric modeling relies on defining objects through parameters and constraints, enabling easy modifications by updating these parameters, which automatically adjust the entire model. It uses history-based features and a feature tree to maintain relationships between components, ensuring design intent is preserved throughout changes. This approach is fundamental in computer-aided design (CAD) software like SolidWorks and Autodesk Inventor, providing structured control for precision engineering tasks.

Fundamental Concepts of Direct Modeling

Direct modeling centers on intuitive manipulation of 3D geometry without relying on predefined parameters or history trees, allowing designers to push, pull, and edit features freely. This approach emphasizes flexibility and speed by enabling direct access to model elements such as faces, edges, and vertices, which promotes rapid iteration and design changes. Unlike parametric modeling, direct modeling does not require constraints or relationships, making it ideal for conceptual design and late-stage modifications.

Key Differences Between Parametric and Direct Modeling

Parametric modeling uses history-based features driven by parameters and constraints, allowing precise control and easy modifications through an editable feature tree, making it ideal for complex, rule-driven designs. Direct modeling enables intuitive manipulation of geometry without predefined parameters, offering faster design changes and flexibility, especially useful for concept development and working with imported models. The key differences lie in parametric modeling's reliance on a structured design history versus direct modeling's freedom from constraints, impacting design workflow and adaptability.

Advantages of Parametric Modeling in Mechanical Engineering

Parametric modeling offers significant advantages in mechanical engineering by enabling precise control over design variables and facilitating easy modifications through parameter adjustments, which accelerates iteration and innovation. It supports complex assemblies with built-in constraints and relationships, ensuring design intent is maintained and reducing errors during updates. This approach enhances collaboration by providing a structured framework that integrates seamlessly with simulation and manufacturing processes, improving overall efficiency and product quality.

Advantages of Direct Modeling in Mechanical Engineering

Direct modeling in mechanical engineering offers significant advantages such as enhanced flexibility for rapid design changes and easier manipulation of geometry without the constraints of predefined parameters. It enables engineers to intuitively modify designs, improving productivity in iterative prototyping and accommodating late-stage alterations more efficiently than parametric modeling. This approach streamlines collaboration across multidisciplinary teams by allowing straightforward adjustments to complex parts and assemblies, accelerating the product development cycle.

Common Applications and Use Cases

Parametric modeling excels in complex product design and engineering, enabling precise control over dimensions and relationships, making it ideal for CAD-driven mechanical parts, architecture, and automotive industries. Direct modeling is favored in rapid prototyping, conceptual design, and industries requiring quick modifications like industrial design and 3D printing. Both approaches serve complementary roles in product development, with parametric suited for detailed, iterative design and direct modeling optimized for flexibility and quick adjustments.

Software Tools Supporting Each Modeling Approach

Parametric modeling is predominantly supported by software tools such as Autodesk Inventor, SolidWorks, and Siemens NX, which offer feature-based, history-driven design environments ideal for precise and easily modifiable models. Direct modeling is favored in tools like SpaceClaim, Onshape, and PTC Creo Direct, providing flexible, intuitive geometry manipulation without reliance on a structured design history. Each software category caters to specific design workflows, with parametric tools excelling in iterative engineering changes and direct modeling software optimized for rapid conceptual design and downstream edits.

Decision Criteria: Choosing the Right Modeling Method

Choosing between parametric modeling and direct modeling depends on project complexity, flexibility requirements, and collaboration needs. Parametric modeling excels in environments where design intent and history-driven changes are critical, enabling precise modifications through feature parameters. Direct modeling suits rapid conceptualization and flexible editing, ideal for design exploration and situations requiring quick, geometry-based adjustments without predefined constraints.

Future Trends in Mechanical CAD Modeling

Future trends in mechanical CAD modeling emphasize the integration of parametric and direct modeling to enhance design flexibility and efficiency. Parametric modeling, known for its rule-based approach and history-driven edits, continues to evolve with AI-driven automation and cloud collaboration, enabling smarter design iterations. Direct modeling gains momentum by providing intuitive, geometry-focused modifications ideal for rapid prototyping and complex assemblies in Industry 4.0 environments.

Constraint-driven design

Parametric modeling utilizes constraint-driven design to define relationships and dependencies between features, enabling easy modifications by adjusting parameters, while direct modeling allows intuitive geometry manipulation without predefined constraints.

Feature-based modeling

Feature-based parametric modeling enables precise control and modification of design intent through editable parameters, whereas direct modeling allows intuitive shape manipulation without predefined features or history.

History tree

Parametric modeling utilizes a history tree to capture design intent and enable feature modifications, while direct modeling eliminates the history tree for flexible, instant geometry edits without predefined constraints.

Geometry editing

Parametric modeling enables precise geometry editing through feature-based constraints and history-driven adjustments, while direct modeling allows intuitive, flexible manipulation of geometry without predefined parameters or history dependencies.

Associativity

Parametric modeling maintains associativity through parameter-driven constraints enabling automatic updates, while direct modeling lacks inherent associativity, allowing flexible geometry editing without predefined relationships.

Synchronous technology

Synchronous technology combines the flexibility of direct modeling with the precision of parametric modeling by enabling real-time, feature-based edits without a history tree.

Design intent

Parametric modeling emphasizes preserving design intent through adjustable parameters and constraints, while direct modeling offers flexibility by allowing immediate geometry edits without predefined relationships.

Freeform manipulation

Parametric modeling enables precise control through adjustable parameters, while direct modeling excels in intuitive freeform manipulation by allowing users to flexibly push, pull, and reshape geometry without predefined constraints.

CAD interoperability

Parametric modeling enhances CAD interoperability by enabling feature-based edits and design history tracking across platforms, while direct modeling offers faster, more flexible geometry manipulation but with limited parametric data exchange.

Regeneration

Parametric modeling relies on feature-based regeneration to update designs through editable parameters, while direct modeling modifies geometry instantaneously without the need for regeneration.

Parametric modeling vs Direct modeling Infographic

njnir.com

njnir.com