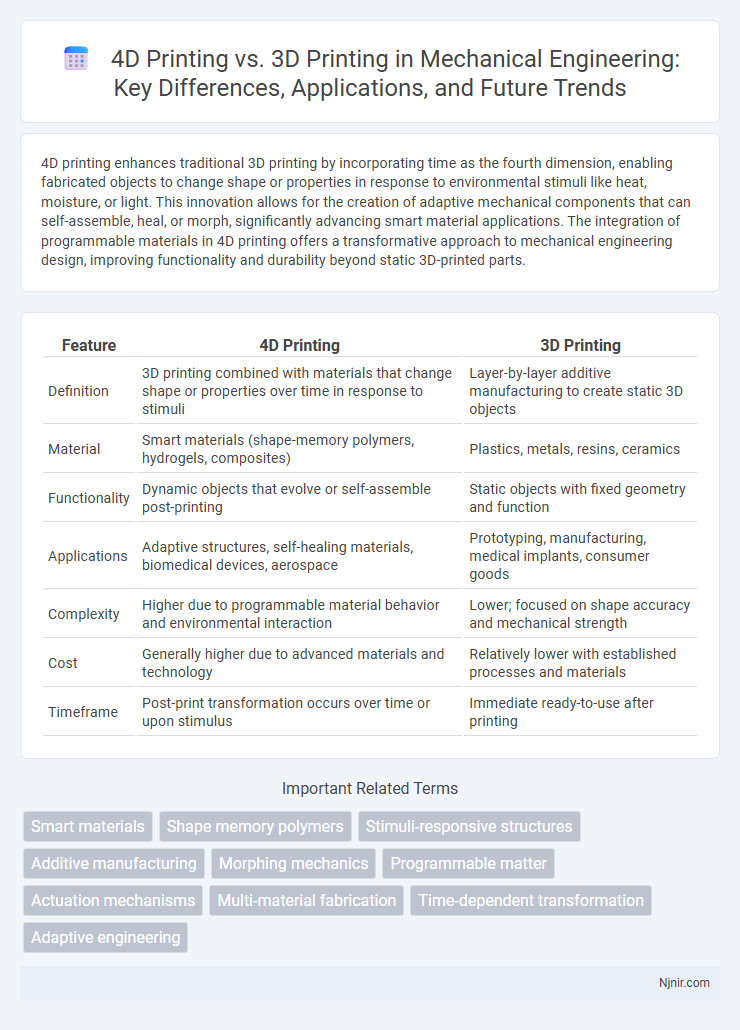

4D printing enhances traditional 3D printing by incorporating time as the fourth dimension, enabling fabricated objects to change shape or properties in response to environmental stimuli like heat, moisture, or light. This innovation allows for the creation of adaptive mechanical components that can self-assemble, heal, or morph, significantly advancing smart material applications. The integration of programmable materials in 4D printing offers a transformative approach to mechanical engineering design, improving functionality and durability beyond static 3D-printed parts.

Table of Comparison

| Feature | 4D Printing | 3D Printing |

|---|---|---|

| Definition | 3D printing combined with materials that change shape or properties over time in response to stimuli | Layer-by-layer additive manufacturing to create static 3D objects |

| Material | Smart materials (shape-memory polymers, hydrogels, composites) | Plastics, metals, resins, ceramics |

| Functionality | Dynamic objects that evolve or self-assemble post-printing | Static objects with fixed geometry and function |

| Applications | Adaptive structures, self-healing materials, biomedical devices, aerospace | Prototyping, manufacturing, medical implants, consumer goods |

| Complexity | Higher due to programmable material behavior and environmental interaction | Lower; focused on shape accuracy and mechanical strength |

| Cost | Generally higher due to advanced materials and technology | Relatively lower with established processes and materials |

| Timeframe | Post-print transformation occurs over time or upon stimulus | Immediate ready-to-use after printing |

Introduction to 3D and 4D Printing

3D printing, or additive manufacturing, builds objects layer-by-layer using materials like plastics, metals, or resins based on digital models. 4D printing extends 3D printing by incorporating smart materials that change shape or properties over time in response to stimuli such as heat, moisture, or light. This dynamic transformation enables applications in self-assembling structures, adaptive medical devices, and responsive textiles.

Key Principles of 3D Printing

3D printing operates on the principle of additive manufacturing, where layers of material are precisely deposited to create three-dimensional objects based on digital models, utilizing techniques such as Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS). The key principles include accurate layer-by-layer fabrication, material control, and dimensional precision, enabling rapid prototyping and custom manufacturing. In contrast, 4D printing builds on 3D printing principles by incorporating smart materials that can change shape or properties over time in response to environmental stimuli, adding a dynamic functional dimension to static 3D-printed structures.

Fundamentals of 4D Printing

4D printing extends the capabilities of 3D printing by incorporating time as the fourth dimension, enabling printed objects to transform their shape, properties, or functionality in response to environmental stimuli such as heat, moisture, or light. This technology primarily utilizes smart materials including shape-memory polymers and hydrogels that react dynamically post-fabrication, allowing for applications in self-assembly, adaptive structures, and responsive devices. The core principles of 4D printing involve programmable material behavior and precise control over stimuli-driven transformations, distinguishing it fundamentally from traditional static 3D printed objects.

Materials Used in 3D vs 4D Printing

3D printing primarily uses thermoplastics, resins, and metals such as PLA, ABS, and titanium, enabling the creation of static, solid objects layer by layer. In contrast, 4D printing incorporates smart materials like shape-memory polymers, hydrogels, and composites that respond to environmental stimuli such as heat, moisture, or light to change shape or properties over time. The integration of these responsive materials distinguishes 4D printing, providing dynamic and adaptable functionalities beyond the fixed forms achievable with traditional 3D printing materials.

Mechanisms of Shape Transformation in 4D Printing

4D printing involves the use of smart materials that undergo programmed shape transformations in response to environmental stimuli such as temperature, moisture, or pH, enabling dynamic changes over time. Unlike 3D printing, which creates static objects, 4D printing integrates time as the fourth dimension by designing structures with shape-memory polymers, hydrogels, or composites that can fold, bend, or self-assemble. These mechanisms rely on the material's internal stresses and molecular behavior to trigger reversible or irreversible deformation, providing innovative applications in aerospace, biomedical devices, and soft robotics.

Applications of 3D Printing in Mechanical Engineering

3D printing in mechanical engineering enables rapid prototyping, allowing engineers to quickly create and test complex components with precise geometries. It facilitates custom manufacturing of lightweight parts for aerospace, automotive, and robotics applications, improving performance while reducing material waste. Unlike 4D printing, which introduces material transformation over time, 3D printing focuses on static, durable structures essential for mechanical assemblies and tooling.

Emerging Applications of 4D Printing

4D printing advances beyond traditional 3D printing by incorporating time-responsive materials that change shape or function in response to environmental stimuli such as heat, moisture, or light. Emerging applications of 4D printing include adaptive medical implants that can morph to fit patient anatomy, self-assembling aerospace components enhancing in-flight performance, and responsive soft robotics for precision tasks. These innovations leverage smart materials and programmable structures, enabling dynamic and sustainable solutions across healthcare, aerospace, and manufacturing industries.

Comparative Analysis: 3D vs 4D Printing

3D printing creates static objects layer by layer using materials like plastics or resins, emphasizing precision and repeatability in manufacturing prototypes and components. 4D printing incorporates smart materials that change shape or properties over time in response to environmental stimuli such as temperature, moisture, or light, enabling dynamic and adaptive applications. The key difference lies in 4D printing's ability to produce self-assembling or self-transforming structures, expanding possibilities in aerospace, biomedical devices, and responsive textiles beyond traditional 3D printing capabilities.

Challenges and Limitations in 3D and 4D Printing

3D printing faces challenges such as limited material options, slower production speeds, and difficulties in creating complex geometries or multi-material objects with high precision. 4D printing extends these limitations by introducing the complexity of time-responsive materials that require advanced design algorithms, smart materials with specific environmental triggers, and challenges in predicting long-term behavior and durability. Both technologies encounter scalability issues and high production costs, with 4D printing demanding greater integration of material science and engineering for functional morphing structures.

Future Trends in Additive Manufacturing Technologies

4D printing advances 3D printing by incorporating smart materials that transform shape or function over time in response to environmental stimuli, enabling adaptive and self-healing structures. Future trends in additive manufacturing emphasize integrating AI-driven design optimization, multi-material printing, and increased automation to enhance precision and scalability. Emerging applications span aerospace, biomedical devices, and soft robotics, where dynamic material behaviors unlock unprecedented performance and customization.

Smart materials

4D printing enhances traditional 3D printing by integrating smart materials that enable objects to self-assemble, transform, or adapt over time in response to environmental stimuli such as temperature, humidity, or light.

Shape memory polymers

4D printing utilizes shape memory polymers that enable printed objects to transform their shape over time in response to environmental stimuli, unlike traditional 3D printing which produces static objects.

Stimuli-responsive structures

4D printing creates stimuli-responsive structures that can change shape or properties over time when exposed to environmental triggers, unlike traditional 3D printing which produces static objects.

Additive manufacturing

4D printing enhances additive manufacturing by using programmable materials that self-transform over time, whereas 3D printing produces static objects layer by layer without shape-shifting capabilities.

Morphing mechanics

4D printing enhances traditional 3D printing by incorporating smart materials that enable printed objects to morph or change shape over time in response to environmental stimuli.

Programmable matter

4D printing enhances 3D printing by integrating programmable matter that autonomously changes shape or properties over time in response to environmental stimuli.

Actuation mechanisms

4D printing incorporates smart materials such as shape-memory polymers and hydrogels that enable self-actuation and transformation over time, while 3D printing relies on static structures without innate actuation capabilities.

Multi-material fabrication

4D printing advances multi-material fabrication by enabling printed objects to change shape or properties over time through stimuli-responsive materials, unlike traditional 3D printing which produces static structures.

Time-dependent transformation

4D printing enables time-dependent transformation by incorporating programmable materials that change shape or function after fabrication, unlike traditional 3D printing which produces static objects.

Adaptive engineering

4D printing advances adaptive engineering by enabling materials to self-transform over time in response to environmental stimuli, unlike 3D printing which produces static objects.

4D printing vs 3D printing Infographic

njnir.com

njnir.com