Friction welding creates strong, defect-free joints through solid-state bonding by generating heat via mechanical friction, making it ideal for dissimilar metals and thick sections. Laser welding offers precise, high-speed fusion with minimal heat input, suitable for complex geometries and thin materials. Choosing between friction welding and laser welding depends on factors like material compatibility, joint design, and thermal sensitivity.

Table of Comparison

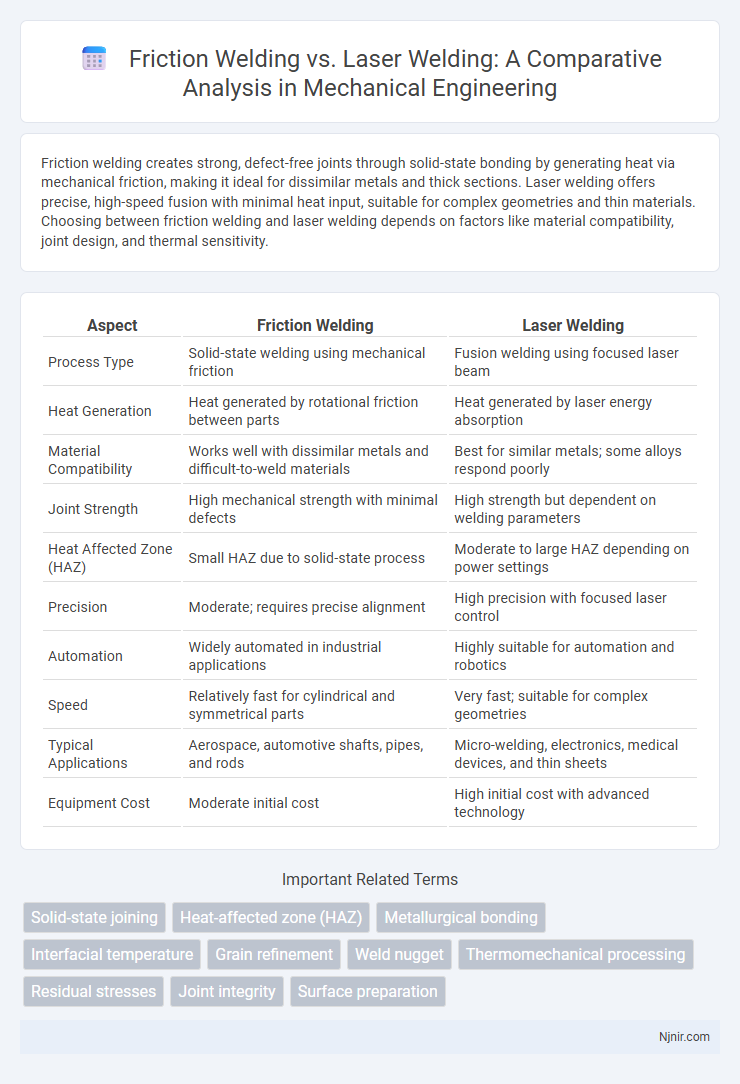

| Aspect | Friction Welding | Laser Welding |

|---|---|---|

| Process Type | Solid-state welding using mechanical friction | Fusion welding using focused laser beam |

| Heat Generation | Heat generated by rotational friction between parts | Heat generated by laser energy absorption |

| Material Compatibility | Works well with dissimilar metals and difficult-to-weld materials | Best for similar metals; some alloys respond poorly |

| Joint Strength | High mechanical strength with minimal defects | High strength but dependent on welding parameters |

| Heat Affected Zone (HAZ) | Small HAZ due to solid-state process | Moderate to large HAZ depending on power settings |

| Precision | Moderate; requires precise alignment | High precision with focused laser control |

| Automation | Widely automated in industrial applications | Highly suitable for automation and robotics |

| Speed | Relatively fast for cylindrical and symmetrical parts | Very fast; suitable for complex geometries |

| Typical Applications | Aerospace, automotive shafts, pipes, and rods | Micro-welding, electronics, medical devices, and thin sheets |

| Equipment Cost | Moderate initial cost | High initial cost with advanced technology |

Introduction to Friction and Laser Welding

Friction welding uses mechanical heat generated by friction between workpieces to create a strong, solid-state bond without melting the materials. Laser welding employs concentrated laser beams to rapidly melt and fuse metals, allowing for precise and high-speed joining of intricate components. Both techniques offer distinct advantages in manufacturing, with friction welding excelling in joining dissimilar metals and laser welding providing high accuracy and minimal thermal distortion.

Fundamental Principles of Friction Welding

Friction welding uses mechanical friction to generate heat at the interface of two workpieces, causing material plasticization and subsequent joining under pressure without melting. This solid-state process involves rotational or linear motion to create intense shear forces that produce the necessary thermal energy for bonding. Unlike laser welding, which relies on highly concentrated light energy to melt and fuse materials, friction welding preserves base material properties by avoiding the liquid phase.

Fundamental Principles of Laser Welding

Laser welding utilizes a concentrated high-energy laser beam to melt and fuse materials at the joint, enabling precise control over heat input and minimal thermal distortion. The process relies on the absorption of laser energy by the workpiece, creating a molten pool that solidifies rapidly to form a strong weld. Unlike friction welding, which generates heat through mechanical friction, laser welding offers superior speed, accuracy, and adaptability for intricate or thin components.

Key Differences Between Friction and Laser Welding

Friction welding relies on mechanical heat generated by rotational or linear motion between two components, making it ideal for joining dissimilar metals with minimal thermal distortion. Laser welding uses a concentrated beam of light to melt and fuse materials precisely, offering high speed and minimal heat-affected zones suitable for thin or delicate parts. Key differences include heat generation methods, joint quality, suitable materials, and production speed, with friction welding excelling in solid-state bonding and laser welding preferred for precision and automation.

Material Compatibility in Friction vs Laser Welding

Friction welding demonstrates superior material compatibility by joining dissimilar metals such as aluminum to steel or titanium alloys without melting, preserving base metal properties and preventing common fusion defects. Laser welding, while offering high precision and minimal heat-affected zones, struggles with certain dissimilar metal combinations due to differences in melting points and thermal conductivities, often requiring additional filler materials. This makes friction welding more versatile for complex material pairings in aerospace and automotive industries where mechanical integrity is critical.

Comparative Joint Strength and Quality

Friction welding produces joints with superior mechanical strength due to its solid-state process that avoids melting, resulting in minimal thermal distortion and excellent metallurgical bonding. Laser welding offers high precision and minimal heat-affected zones, but the rapid cooling can lead to residual stresses and potential defects like porosity, affecting joint quality. In terms of comparative joint strength and quality, friction welding typically achieves more consistent and robust welds for heavy-duty applications, while laser welding excels in fine, delicate assemblies requiring precision and minimal distortion.

Process Efficiency and Cycle Time

Friction welding offers high process efficiency by generating heat through mechanical friction, enabling rapid solid-state joining with minimal energy consumption and reduced material distortion. Laser welding provides precise energy input, allowing for faster cycle times in thin materials and complex geometries, but often requires higher power consumption and more cooling time. Comparing both, friction welding excels in joining thicker or dissimilar metals quickly, while laser welding is ideal for high-speed automation and intricate, fine-detail welds.

Energy Consumption and Cost Analysis

Friction welding generally consumes less energy compared to laser welding due to its mechanical joining process that avoids high-power laser generation. The cost analysis shows friction welding requires lower initial equipment investment and maintenance expenses, making it more economical for high-volume production. Laser welding, while offering precision and minimal post-processing, incurs higher energy costs and capital expenditure, limiting its cost efficiency in large-scale industrial applications.

Typical Applications in Mechanical Engineering

Friction welding is commonly used in mechanical engineering for joining dissimilar metals in automotive drive shafts, aerospace components, and heavy machinery parts due to its strong, defect-free joints and minimal heat-affected zones. Laser welding excels in precision applications such as micro-welding of fuel injectors, high-speed manufacturing of engine components, and intricate sealing of sensors, offering high speed and minimal distortion. Both methods enhance mechanical performance but are selected based on part geometry, material compatibility, and production volume requirements.

Future Trends in Welding Technologies

Future trends in welding technologies emphasize increased automation and precision, with friction welding evolving through enhanced control systems and real-time monitoring to improve joint strength and reduce cycle times. Laser welding advancements focus on higher power density and beam shaping techniques, enabling faster processes and minimal heat input, ideal for thin materials and complex geometries. Integration of artificial intelligence and machine learning in both methods is driving predictive maintenance and adaptive welding parameters, optimizing efficiency and quality in manufacturing industries.

Solid-state joining

Friction welding and laser welding are both advanced solid-state joining techniques, with friction welding utilizing mechanical heat generated by friction to join metals without melting, while laser welding uses concentrated light energy to produce precise, high-strength joints with minimal thermal distortion.

Heat-affected zone (HAZ)

Friction welding produces a narrower and more controlled heat-affected zone (HAZ) compared to laser welding, resulting in less thermal distortion and improved mechanical properties in the welded joint.

Metallurgical bonding

Friction welding creates a strong metallurgical bond through plastic deformation and solid-state diffusion, while laser welding relies on melting and solidification to form the bond.

Interfacial temperature

Friction welding generates higher interfacial temperatures through mechanical friction and plastic deformation, enhancing metallurgical bonding, whereas laser welding achieves localized, high-intensity heating with rapid cooling, resulting in distinct thermal gradients at the interface.

Grain refinement

Friction welding produces superior grain refinement through intense plastic deformation and dynamic recrystallization, while laser welding achieves grain refinement primarily via rapid solidification and controlled heat input.

Weld nugget

Friction welding produces a dense, defect-free weld nugget with superior mechanical properties, while laser welding creates a fine, precise weld nugget ideal for high-speed, low-heat applications.

Thermomechanical processing

Friction welding provides superior thermomechanical processing by generating localized plastic deformation and controlled heat input, while laser welding relies on concentrated thermal energy with minimal mechanical impact, affecting microstructural evolution and joint integrity differently.

Residual stresses

Friction welding typically generates lower residual stresses compared to laser welding, resulting in improved joint integrity and reduced risk of cracking.

Joint integrity

Friction welding produces superior joint integrity by creating strong, defect-free bonds through solid-state forging, while laser welding offers high precision but may introduce burn-through defects affecting joint strength.

Surface preparation

Friction welding requires minimal surface preparation with clean, oxide-free surfaces for optimal bonding, whereas laser welding demands precise surface cleaning and smoothness to ensure accurate energy absorption and weld quality.

friction welding vs laser welding Infographic

njnir.com

njnir.com