Direct drive systems eliminate the need for intermediate gears, resulting in higher efficiency, reduced maintenance, and improved reliability by minimizing mechanical losses and wear. Geared drives offer greater torque multiplication and speed variation, making them suitable for applications requiring precise speed control and high torque output. Selection between direct and geared drives depends on factors such as load requirements, space constraints, and desired performance characteristics in mechanical engineering designs.

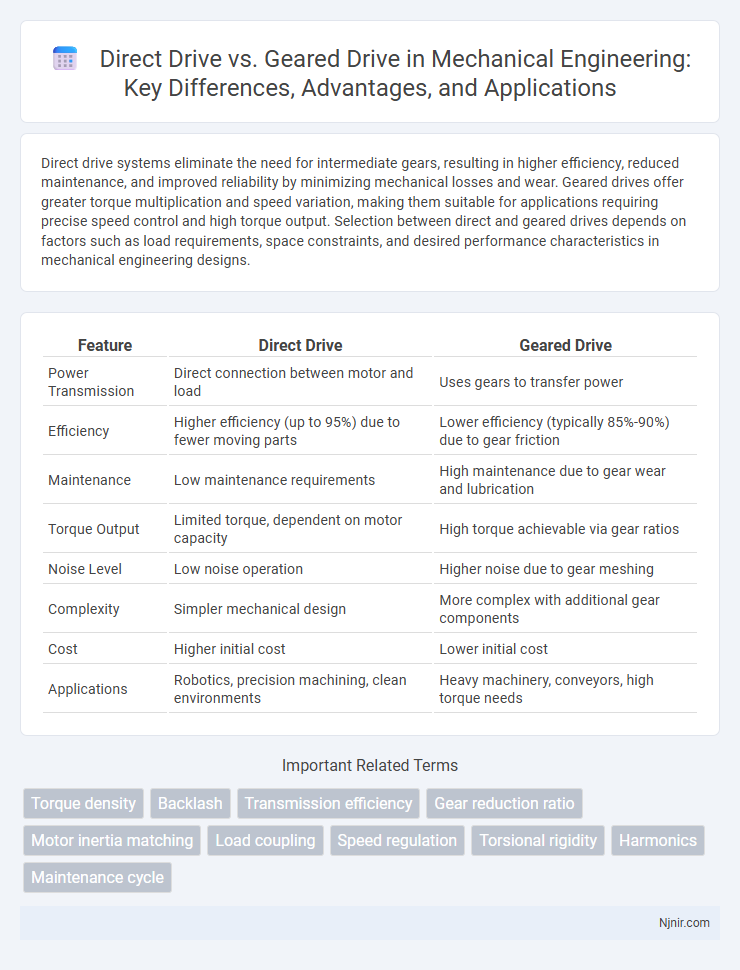

Table of Comparison

| Feature | Direct Drive | Geared Drive |

|---|---|---|

| Power Transmission | Direct connection between motor and load | Uses gears to transfer power |

| Efficiency | Higher efficiency (up to 95%) due to fewer moving parts | Lower efficiency (typically 85%-90%) due to gear friction |

| Maintenance | Low maintenance requirements | High maintenance due to gear wear and lubrication |

| Torque Output | Limited torque, dependent on motor capacity | High torque achievable via gear ratios |

| Noise Level | Low noise operation | Higher noise due to gear meshing |

| Complexity | Simpler mechanical design | More complex with additional gear components |

| Cost | Higher initial cost | Lower initial cost |

| Applications | Robotics, precision machining, clean environments | Heavy machinery, conveyors, high torque needs |

Introduction to Direct Drive and Geared Drive Systems

Direct drive systems connect the motor directly to the load, eliminating intermediate gears and reducing mechanical losses, which enhances efficiency and precision. Geared drive systems use a series of gears to reduce motor speed and increase torque, offering greater force at the expense of added complexity and maintenance requirements. Understanding the differences in torque delivery, efficiency, and mechanical simplicity is essential for selecting the optimal drive system in applications such as robotics, industrial machinery, and electric vehicles.

Fundamental Principles of Direct Drive Mechanisms

Direct drive mechanisms eliminate intermediate components such as gears or belts, enabling the motor to connect directly to the load. This fundamental design reduces energy losses, improves torque delivery, and enhances system responsiveness by minimizing backlash and friction. Essential components include high-torque motors and precision control systems that ensure smooth operation and increased efficiency in applications like robotics and industrial machinery.

Key Components and Design Aspects of Geared Drives

Geared drives rely on a system of gears, typically including a pinion and a larger gear wheel, to transmit torque and adjust rotational speed, providing precise control and increased torque output. The key components of geared drives include the gearbox housing, bearings, shafts, gears (such as spur, helical, or planetary), and lubrication systems that ensure efficient power transmission and reduce wear. The design aspects focus on gear type selection, gear ratio optimization, material strength, and heat dissipation to maximize durability, efficiency, and noise reduction in applications requiring varying torque and speed.

Comparative Analysis: Efficiency and Power Transmission

Direct drive systems offer higher efficiency by eliminating energy losses associated with gears, resulting in more precise power transmission and reduced maintenance. Geared drive systems provide torque multiplication and speed variability but suffer from frictional losses and increased wear, lowering overall efficiency. For applications demanding high precision and energy conservation, direct drive is favorable, whereas geared drives are preferred for cost-effective torque customization.

Precision and Accuracy: Direct vs Geared Systems

Direct drive systems offer superior precision and accuracy due to the elimination of backlash and minimal mechanical components, resulting in smoother and more consistent motion control. Geared drive systems, while capable of high torque, often introduce backlash and mechanical play that can reduce positional accuracy in sensitive applications. For industries demanding exact positioning, such as robotics and CNC machinery, direct drive mechanisms provide more reliable and repeatable performance.

Maintenance Requirements and Lifespan Considerations

Direct drive systems feature fewer moving parts, significantly reducing maintenance requirements and minimizing wear over time. Geared drive systems require regular lubrication and inspection due to gear wear and potential misalignment, impacting overall operational reliability. Lifespan considerations favor direct drive for longer service intervals and durability, while geared drives may experience shorter lifespans due to mechanical stress on gears.

Noise, Vibration, and Operational Smoothness

Direct drive systems generate less noise and vibration due to the absence of intermediary gears, resulting in quieter operation. The elimination of gears reduces mechanical friction and backlash, enhancing operational smoothness and precision. In contrast, geared drive systems often produce more noise and vibration from gear meshing, which can impact the overall riding experience and drivetrain efficiency.

Cost Implications: Initial Investment and Long-term Expenses

Direct drive systems typically have a higher initial investment due to advanced technology and precision components but offer lower maintenance costs over time by eliminating gears and reducing wear. Geared drives generally require a lower upfront cost but incur higher long-term expenses due to gear replacements, lubrication, and potential efficiency losses. Analyzing operational lifespan and maintenance frequency is crucial when comparing total cost of ownership between direct drive and geared drive setups.

Application Suitability in Mechanical Engineering Fields

Direct drive systems offer high precision and efficiency, making them ideal for applications requiring minimal backlash and smooth torque delivery, such as robotics and CNC machinery. Geared drives provide higher torque multiplication and are better suited for heavy load-bearing tasks like conveyor belts and automotive transmissions. Choosing between the two depends on the specific mechanical engineering requirements for speed, torque, and accuracy in the intended application.

Future Trends and Innovations in Drive Technology

Direct drive systems offer higher efficiency and reduced maintenance by eliminating mechanical components like gears, making them ideal for future applications in electric vehicles and renewable energy. Innovations in geared drives are focused on advanced materials and precision engineering to enhance durability and torque density while minimizing noise and vibration. Emerging trends include integrating smart sensors and AI-driven controls in both drive types to optimize performance, predictive maintenance, and energy management for Industry 4.0 and smart infrastructure.

Torque density

Direct drive systems offer higher torque density by eliminating gear losses and enabling compact, efficient power transmission compared to geared drive systems.

Backlash

Direct drive systems eliminate backlash by transmitting torque directly from the motor to the load, while geared drives inherently introduce backlash due to gear tooth clearance and spacing.

Transmission efficiency

Direct drive systems typically offer higher transmission efficiency than geared drives by minimizing energy losses through fewer mechanical components.

Gear reduction ratio

Direct drive systems offer a gear reduction ratio of 1:1 for maximum efficiency and minimal maintenance, while geared drive systems utilize varying gear reduction ratios to increase torque and adjust speed according to application requirements.

Motor inertia matching

Direct drive systems feature low motor inertia closely matched to the load, enhancing responsiveness and precision compared to geared drives with higher reflected inertia.

Load coupling

Direct drive systems provide superior load coupling by minimizing mechanical backlash and torque ripple compared to geared drive systems.

Speed regulation

Direct drive systems provide more precise and consistent speed regulation compared to geared drives due to fewer mechanical components and reduced backlash.

Torsional rigidity

Direct drive systems offer superior torsional rigidity compared to geared drives, resulting in enhanced torque transmission and reduced backlash.

Harmonics

Direct drive systems exhibit lower harmonic distortion due to the absence of intermediary gears, resulting in smoother torque delivery compared to geared drive systems, which tend to introduce higher harmonics from gear meshing.

Maintenance cycle

Direct drive systems require significantly less frequent maintenance cycles than geared drives due to fewer moving parts and reduced wear.

Direct drive vs geared drive Infographic

njnir.com

njnir.com