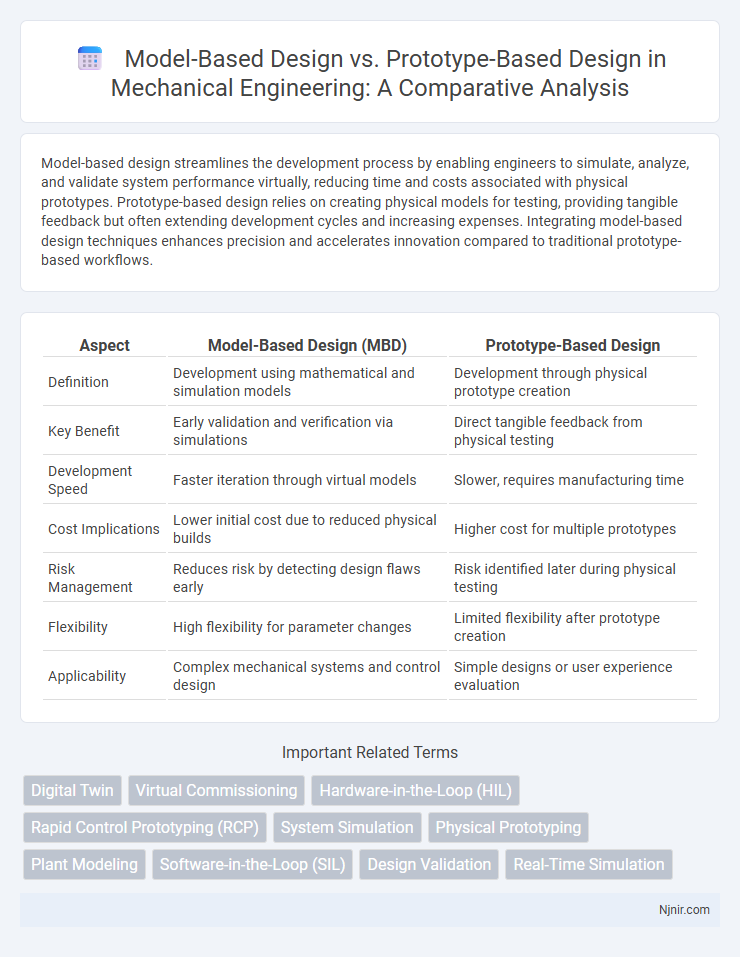

Model-based design streamlines the development process by enabling engineers to simulate, analyze, and validate system performance virtually, reducing time and costs associated with physical prototypes. Prototype-based design relies on creating physical models for testing, providing tangible feedback but often extending development cycles and increasing expenses. Integrating model-based design techniques enhances precision and accelerates innovation compared to traditional prototype-based workflows.

Table of Comparison

| Aspect | Model-Based Design (MBD) | Prototype-Based Design |

|---|---|---|

| Definition | Development using mathematical and simulation models | Development through physical prototype creation |

| Key Benefit | Early validation and verification via simulations | Direct tangible feedback from physical testing |

| Development Speed | Faster iteration through virtual models | Slower, requires manufacturing time |

| Cost Implications | Lower initial cost due to reduced physical builds | Higher cost for multiple prototypes |

| Risk Management | Reduces risk by detecting design flaws early | Risk identified later during physical testing |

| Flexibility | High flexibility for parameter changes | Limited flexibility after prototype creation |

| Applicability | Complex mechanical systems and control design | Simple designs or user experience evaluation |

Introduction to Model-Based and Prototype-Based Design

Model-based design relies on creating detailed mathematical and simulation models to represent system behavior before implementation, enabling accurate analysis and validation. Prototype-based design emphasizes building functional hardware or software prototypes early in the development process to test concepts and gather real-world feedback. Both approaches aim to reduce errors and improve system performance, but model-based design prioritizes virtual iteration while prototype-based design focuses on tangible experimentation.

Core Principles of Model-Based Design

Model-based design centers on creating detailed mathematical and simulation models that represent system behavior, enabling early validation and iterative refinement. It relies on principles of abstraction, modularity, and reusability to ensure accurate representation and efficient development cycles. This approach contrasts with prototype-based design, which emphasizes physical or functional prototypes primarily for user feedback and empirical testing.

Core Principles of Prototype-Based Design

Prototype-based design centers on creating tangible models that users interact with to refine requirements and functionality, allowing iterative feedback-driven development. It emphasizes flexibility by evolving prototypes through continuous user input rather than relying on fixed initial specifications. This approach fosters a user-centered design process that adapts to changing needs and reduces misunderstanding in complex system development.

Comparative Workflow: Model-Based vs Prototype-Based

Model-based design emphasizes developing and validating system models early in the workflow, enabling simulation and automated code generation to identify issues before physical implementation. Prototype-based design centers on building and testing physical or functional prototypes iteratively, offering hands-on validation but often incurring higher costs and longer development cycles. Model-based workflows streamline design optimization and reduce time-to-market through virtual testing, while prototype-based approaches provide tangible feedback for refinement but may delay product iteration.

Advantages of Model-Based Design in Mechanical Engineering

Model-based design in mechanical engineering streamlines the development process by enabling precise simulations and virtual testing, reducing the need for costly physical prototypes. It enhances collaboration across engineering teams through shared, data-rich models that improve accuracy and consistency. This approach accelerates innovation cycles and supports better decision-making by integrating multidisciplinary data within a single, adaptable platform.

Benefits and Limitations of Prototype-Based Design

Prototype-based design offers quick validation of concepts by creating functional models early in the development process, enabling rapid user feedback and iterative improvements. This approach reduces misunderstandings between stakeholders and developers, but it may lead to increased costs if excessive prototyping is required or if prototypes deviate significantly from the final product. Limitations include potential scope creep and the risk that prototypes are misinterpreted as nearly finished solutions, hindering proper project planning and resource allocation.

Cost Implications: Modeling vs Prototyping

Model-based design typically reduces long-term costs by enabling early detection of errors through simulation and iterative refinement, minimizing expensive physical rework. Prototyping often incurs higher initial expenses due to material, labor, and manufacturing costs but provides tangible insights that can prevent costly design flaws. Investment in model-based design tools can lead to improved resource allocation, while prototyping remains essential for validating complex user interactions and material properties.

Impact on Product Development Cycle

Model-based design accelerates the product development cycle by enabling early validation through virtual simulations, reducing the need for physical prototypes and allowing faster iterations. Prototype-based design relies heavily on building and testing physical models, which can extend development time due to material costs and manufacturing delays. As a result, model-based design often leads to more efficient, cost-effective, and streamlined product development processes.

Case Studies: Model-Based Versus Prototype-Based Approaches

Case studies comparing model-based design and prototype-based design reveal that model-based approaches excel in early error detection and system simulation, reducing development costs and enhancing accuracy through formal verification methods. Prototype-based design offers tangible, user-focused iterations that improve usability feedback and adaptability during the development cycle. Industries such as automotive and aerospace leverage model-based design for complex system integration, while software startups often prefer prototype-based design to accelerate user-centered validation.

Choosing the Right Design Methodology for Your Project

Model-based design emphasizes creating detailed digital simulations and system models to predict performance and optimize workflows, ideal for complex, safety-critical projects requiring high accuracy. Prototype-based design focuses on building tangible, functional prototypes to iteratively test and refine concepts, best suited for user-experience-driven projects needing rapid feedback and physical validation. Selecting the right design methodology depends on project complexity, development timeline, resource availability, and the need for early performance verification versus hands-on experimentation.

Digital Twin

Model-based design enables the creation of accurate Digital Twins by simulating system behavior through comprehensive mathematical models, while prototype-based design relies on physical iterations that are less efficient for real-time Digital Twin updates.

Virtual Commissioning

Model-based design enables efficient Virtual Commissioning by using detailed digital twins to simulate and validate system behavior before physical prototypes are built, whereas prototype-based design relies heavily on physical iterations, increasing cost and time.

Hardware-in-the-Loop (HIL)

Model-based design enhances Hardware-in-the-Loop (HIL) testing accuracy by enabling early system validation through detailed simulation models, while prototype-based design relies on physical prototypes that may delay detection of system integration issues.

Rapid Control Prototyping (RCP)

Model-based design accelerates Rapid Control Prototyping (RCP) by enabling real-time system simulation and direct code generation, whereas prototype-based design relies on physical hardware iteration, resulting in slower development cycles and limited adaptability.

System Simulation

Model-based design enables precise system simulation through mathematical representations and automated code generation, while prototype-based design relies on physical models that offer limited simulation flexibility and scalability.

Physical Prototyping

Model-based design minimizes the need for physical prototyping by using accurate simulations and virtual models, whereas prototype-based design relies heavily on creating multiple physical prototypes for testing and validation.

Plant Modeling

Model-based design enables accurate plant modeling through mathematical representations and simulations, while prototype-based design relies on physical models for iterative testing and validation.

Software-in-the-Loop (SIL)

Model-based design enhances Software-in-the-Loop (SIL) testing by enabling early validation of system behavior through executable models, whereas prototype-based design relies on physical prototypes that delay SIL integration and increase development time.

Design Validation

Model-based design enhances design validation by enabling early detection of errors through simulation and formal verification, whereas prototype-based design relies on physical prototypes that can delay identifying design flaws and increase development costs.

Real-Time Simulation

Model-based design enables accurate real-time simulation through early system validation and iterative refinement, while prototype-based design relies on physical hardware testing, limiting simulation speed and flexibility.

Model-based design vs prototype-based design Infographic

njnir.com

njnir.com