Friction stir welding (FSW) produces stronger, defect-free joints by mechanically stirring materials together without melting, unlike traditional welding methods that rely on melting and solidification, which can introduce cracks and distortions. FSW excels in joining lightweight alloys such as aluminum with less thermal distortion and residual stress, improving fatigue performance and structural integrity. Traditional welding offers versatility for a broad range of metals and thicknesses but often requires post-weld treatments to address heat-affected zones and potential weaknesses.

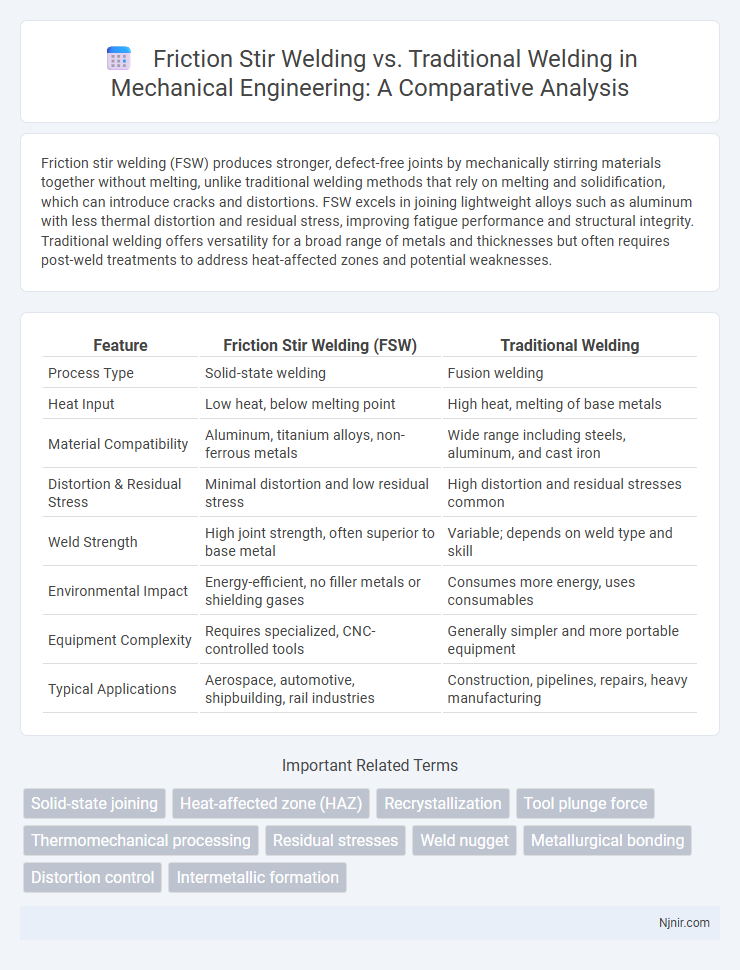

Table of Comparison

| Feature | Friction Stir Welding (FSW) | Traditional Welding |

|---|---|---|

| Process Type | Solid-state welding | Fusion welding |

| Heat Input | Low heat, below melting point | High heat, melting of base metals |

| Material Compatibility | Aluminum, titanium alloys, non-ferrous metals | Wide range including steels, aluminum, and cast iron |

| Distortion & Residual Stress | Minimal distortion and low residual stress | High distortion and residual stresses common |

| Weld Strength | High joint strength, often superior to base metal | Variable; depends on weld type and skill |

| Environmental Impact | Energy-efficient, no filler metals or shielding gases | Consumes more energy, uses consumables |

| Equipment Complexity | Requires specialized, CNC-controlled tools | Generally simpler and more portable equipment |

| Typical Applications | Aerospace, automotive, shipbuilding, rail industries | Construction, pipelines, repairs, heavy manufacturing |

Introduction to Welding Techniques

Friction stir welding (FSW) is a solid-state joining process that uses a rotating tool to generate frictional heat and plastic deformation, creating a high-strength weld without melting the base materials, unlike traditional welding methods that rely on melting and fusion. Traditional welding techniques, such as arc welding and gas welding, often introduce thermal distortion, residual stresses, and require filler materials, which can compromise joint integrity. FSW offers advantages including lower distortion, improved mechanical properties, and the ability to weld difficult-to-fuse materials, making it a preferred choice in aerospace and automotive industries.

Fundamentals of Friction Stir Welding

Friction stir welding (FSW) is a solid-state joining process that uses a non-consumable rotating tool to generate frictional heat, softening materials without reaching their melting point. Unlike traditional welding methods that rely on melting and solidification, FSW produces joints with superior mechanical properties by avoiding common defects such as porosity and distortion. The fundamental mechanism involves plastic deformation and recrystallization in the welding zone, resulting in fine-grained microstructures and enhanced joint integrity.

Overview of Traditional Welding Methods

Traditional welding methods, such as arc welding, MIG (Metal Inert Gas), and TIG (Tungsten Inert Gas), use high heat to melt and join metals, creating strong fusion joints. These techniques are widely applied across industries but often involve risks like distortion, residual stress, and the need for filler materials. Welding performance depends on factors like heat input, electrode type, and skill level, which can affect the quality and integrity of the weld.

Heat Generation and Process Temperatures

Friction stir welding generates heat through mechanical friction between the rotating tool and the workpiece, maintaining lower peak temperatures compared to traditional welding, which relies on high-temperature melting of materials. Process temperatures in friction stir welding typically range between 400degC and 600degC, significantly reducing thermal distortion and residual stresses. In contrast, traditional welding methods such as arc welding can exceed 1500degC, causing greater heat-affected zones and microstructural changes in the welded materials.

Mechanical Properties of Welded Joints

Friction stir welding (FSW) produces welded joints with superior mechanical properties, including enhanced tensile strength and fatigue resistance, compared to traditional fusion welding methods such as arc welding. The solid-state nature of FSW eliminates defects like porosity and cracking, resulting in improved weld microstructure and reduced residual stresses. These characteristics lead to consistently higher joint performance, especially in aluminum alloys and other difficult-to-weld materials.

Material Compatibility and Limitations

Friction stir welding excels in joining lightweight and dissimilar materials such as aluminum alloys, magnesium, and copper, which are often challenging for traditional fusion welding methods due to high heat input and metallurgical defects. Traditional welding techniques, including arc and gas welding, often face limitations with materials prone to cracking or distortion, such as aluminum and titanium, and require filler materials for effective bonding. Friction stir welding's solid-state process reduces thermal distortion and avoids common fusion defects, but it is limited to materials with sufficient plasticity and is currently less effective for ferrous metals and high-thickness variations.

Energy Efficiency and Environmental Impact

Friction stir welding (FSW) significantly reduces energy consumption by eliminating the need for filler materials and high electrical currents compared to traditional arc welding methods. This process produces fewer greenhouse gas emissions and minimizes hazardous fumes, resulting in a lower environmental footprint. FSW's ability to join metals at lower temperatures enhances energy efficiency and promotes sustainable manufacturing practices.

Applications in Modern Manufacturing

Friction stir welding (FSW) is widely utilized in aerospace and automotive industries for joining aluminum alloys with high precision and minimal distortion, outperforming traditional welding in creating strong, defect-free joints. Traditional welding methods, such as arc welding and laser welding, remain prevalent in heavy industry and construction due to their versatility across diverse metals and thicker materials. The growing adoption of FSW in manufacturing of lightweight structures and electric vehicle components underscores its role in advancing high-strength, energy-efficient production processes.

Quality Control and Defect Rates

Friction stir welding (FSW) offers superior quality control compared to traditional welding methods due to its solid-state process, which minimizes common defects such as porosity, cracks, and distortion. The controlled heat input and mechanical stirring in FSW result in consistent weld properties and significantly lower defect rates, enhancing joint integrity and reducing post-weld inspection requirements. Traditional welding techniques, especially fusion welding, often exhibit higher variability in quality and increased susceptibility to defects caused by excessive heat and material melting.

Cost Analysis and Process Economics

Friction stir welding (FSW) generally offers lower overall costs compared to traditional welding methods due to reduced energy consumption and minimal need for filler materials or shielding gases. The process economics favor FSW in high-volume manufacturing, as its automation potential and reduced post-weld processing decrease labor costs and improve production efficiency. Despite higher initial equipment investment, FSW delivers long-term cost savings through improved joint quality, lower defect rates, and less rework.

Solid-state joining

Friction stir welding is a solid-state joining process that produces stronger, defect-free joints with lower distortion compared to traditional fusion welding methods.

Heat-affected zone (HAZ)

Friction stir welding significantly reduces the heat-affected zone (HAZ) compared to traditional welding, resulting in minimized thermal distortion and improved mechanical properties.

Recrystallization

Friction stir welding promotes dynamic recrystallization resulting in finer, equiaxed grains and improved mechanical properties compared to the coarse, uneven grain structure formed during recrystallization in traditional welding methods.

Tool plunge force

Friction stir welding requires significantly lower tool plunge force compared to traditional welding methods, resulting in reduced tool wear and enhanced joint quality.

Thermomechanical processing

Friction stir welding generates less thermal distortion and superior grain refinement compared to traditional welding, optimizing the thermomechanical processing for enhanced joint strength and reduced residual stresses.

Residual stresses

Friction stir welding generates significantly lower residual stresses compared to traditional welding methods, resulting in improved structural integrity and reduced distortion.

Weld nugget

Friction stir welding produces a defect-free, fine-grained weld nugget with superior mechanical properties compared to the coarse, heterogeneous weld nugget often formed in traditional welding methods.

Metallurgical bonding

Friction stir welding creates superior metallurgical bonding by solid-state joining, eliminating melting and reducing defects common in traditional fusion welding methods.

Distortion control

Friction stir welding significantly reduces distortion compared to traditional welding by using a solid-state process that generates less heat and minimizes thermal stresses.

Intermetallic formation

Friction stir welding minimizes intermetallic compound formation compared to traditional welding by using solid-state joining without melting, leading to improved joint strength and reduced brittleness.

Friction stir welding vs traditional welding Infographic

njnir.com

njnir.com