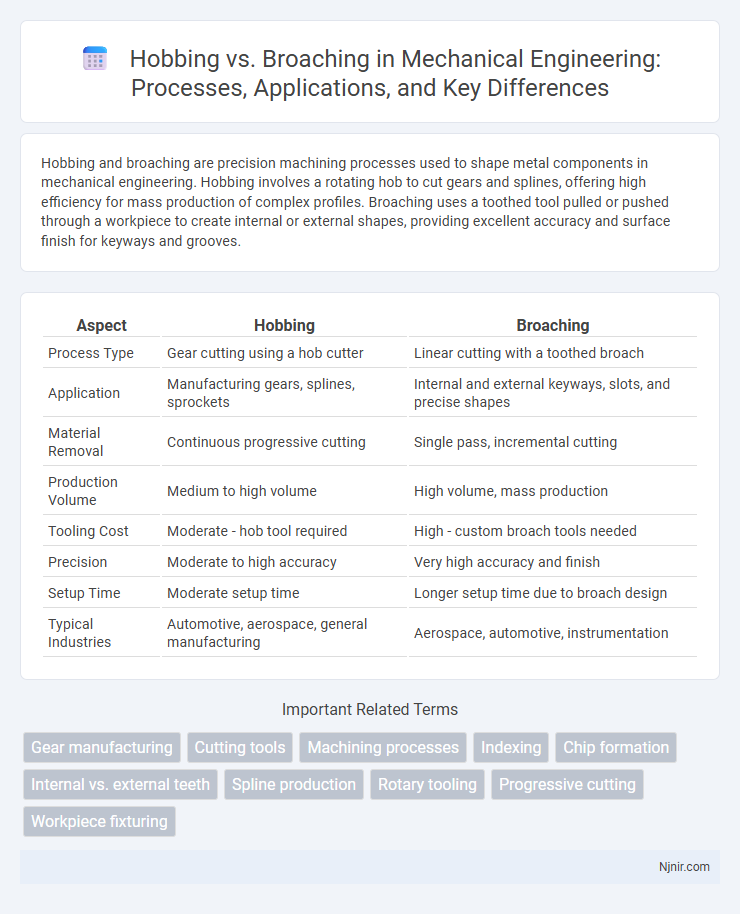

Hobbing and broaching are precision machining processes used to shape metal components in mechanical engineering. Hobbing involves a rotating hob to cut gears and splines, offering high efficiency for mass production of complex profiles. Broaching uses a toothed tool pulled or pushed through a workpiece to create internal or external shapes, providing excellent accuracy and surface finish for keyways and grooves.

Table of Comparison

| Aspect | Hobbing | Broaching |

|---|---|---|

| Process Type | Gear cutting using a hob cutter | Linear cutting with a toothed broach |

| Application | Manufacturing gears, splines, sprockets | Internal and external keyways, slots, and precise shapes |

| Material Removal | Continuous progressive cutting | Single pass, incremental cutting |

| Production Volume | Medium to high volume | High volume, mass production |

| Tooling Cost | Moderate - hob tool required | High - custom broach tools needed |

| Precision | Moderate to high accuracy | Very high accuracy and finish |

| Setup Time | Moderate setup time | Longer setup time due to broach design |

| Typical Industries | Automotive, aerospace, general manufacturing | Aerospace, automotive, instrumentation |

Introduction to Hobbing and Broaching

Hobbing and broaching are precision machining processes used to create complex geometries, primarily gears and internal profiles. Hobbing employs a rotating hob tool to progressively cut gear teeth, making it ideal for high-volume gear manufacturing with consistent accuracy. Broaching uses a toothed tool pulled or pushed through a workpiece to remove material in a single pass, suited for creating internal features such as keyways, splines, and holes with high precision.

Fundamental Principles of Hobbing

Hobbing is a gear cutting process that utilizes a specialized tool called a hob, rotating in synchronization with the workpiece to progressively cut gear teeth via continuous material removal. The fundamental principle of hobbing involves the generation of gear profiles through the relative motion of the hob and workpiece, enabling efficient production of spur, helical, and worm gears with high precision. This method contrasts with broaching, which removes material in a single pass using a toothed tool, making hobbing more suitable for complex gear geometries and large-scale manufacturing.

Fundamental Principles of Broaching

Broaching is a machining process that removes material using a toothed tool called a broach, which moves linearly relative to the workpiece to cut surfaces with precision. The fundamental principle of broaching involves multiple cutting teeth of increasing size sequentially engaging the material, allowing for efficient and accurate shaping of internal or external profiles. This method excels in producing complex geometries with consistent finish and tight tolerances, particularly in applications requiring keyways, splines, or holes.

Tool Design Differences

Hobbing tools feature a cylindrical hob with helical cutting edges designed to progressively generate gear teeth through continuous rotation, optimizing material removal and accuracy in gear manufacturing. Broaching tools consist of a series of sequentially larger cutting teeth arranged on a linear bar, enabling precise shaping of internal or external profiles by pulling or pushing through the workpiece. The primary tool design difference lies in the rotational cutting action of hobs versus the linear, multi-tooth arrangement of broaches, influencing their application scope and machining efficiency.

Material Compatibility

Hobbing is highly compatible with tough materials such as hardened steel and titanium alloys, making it ideal for producing precise gears in automotive and aerospace industries. Broaching excels in machining softer materials like aluminum and brass, offering efficiency in shaping complex internal profiles. Selecting between hobbing and broaching depends on the material's hardness and desired surface finish quality.

Application Areas in Industry

Hobbing is widely used in automotive and aerospace industries for producing high-precision gears, splines, and sprockets due to its efficiency in creating complex gear profiles. Broaching is preferred in manufacturing sectors requiring internal keyways, splines, and intricate hole shapes, such as in the production of turbine blades and hydraulic components. Both machining processes are critical in heavy machinery and tool-making industries for their precision and ability to handle different material hardness levels.

Accuracy and Surface Finish Comparison

Hobbing typically achieves moderate accuracy with typical tolerances around +-0.005 mm, suitable for gears and splines, while broaching delivers higher precision, often reaching tolerances as tight as +-0.001 mm, making it ideal for keyways and internal features. Surface finish from broaching generally surpasses hobbing, with roughness values commonly below Ra 0.4 um compared to hobbing's Ra 0.8-1.6 um, due to continuous cutting action and reduced tool vibration. The enhanced surface finish and accuracy in broaching result from its linear cutting motion and single-pass capability, whereas hobbing involves multi-tooth engagement affecting consistency.

Process Speed and Efficiency

Hobbing offers high process speed for producing gears with complex profiles due to its continuous cutting action, making it ideal for medium to large production runs. Broaching, although slower as a linear cutting process, excels in efficiency for complex internal shapes and keyways with excellent surface finish in single-pass operations. In terms of overall efficiency, hobbing maximizes throughput in gear manufacturing, while broaching is more efficient for precision internal machining where setup and tool changes are minimized.

Cost Considerations

Hobbing generally incurs higher initial equipment costs due to the complexity of hob machines but offers lower per-piece costs in high-volume production, making it cost-effective for large batch runs. Broaching requires less expensive tooling but often results in higher costs for complex or precision parts and is better suited for small to medium production volumes. Tool wear and maintenance expenses vary between methods, influencing overall cost efficiency depending on the specific application and production scale.

Selection Criteria for Manufacturing Processes

Hobbing is preferred for producing gears with high precision and efficiency, suitable for medium to large production runs, emphasizing continuous cutting with a hob cutter. Broaching excels in creating complex internal shapes like keyways or splines with tight tolerances, ideal for short to medium batch sizes and hard materials. Selection depends on factors such as part geometry, production volume, surface finish requirements, and material hardness.

Gear manufacturing

Hobbing offers faster, more versatile gear manufacturing for various gear types with high precision, while broaching provides superior accuracy for internal gear profiles and splines in high-volume production.

Cutting tools

Hobbing uses a rotating hob cutter to generate gears through continuous indexing, while broaching employs a linear broach tool with successive cutting edges to produce precise internal or external profiles.

Machining processes

Hobbing is a versatile machining process ideal for cutting gears with continuous rotary motion using a hob, while broaching is a precision machining method that involves linear tool movement to remove material in complex or internal profiles.

Indexing

Hobbing offers continuous indexing with high precision for complex gear profiles, while broaching typically uses linear, fixed indexing suited for simpler internal shapes.

Chip formation

Hobbing produces continuous spiral chips through rotating cutting edges, while broaching generates segmented chips by reciprocating linear cutting action.

Internal vs. external teeth

Hobbing is primarily used for cutting external teeth with high precision and speed, while broaching is more effective for creating internal teeth with complex profiles and tighter tolerances.

Spline production

Hobbing produces splines through a continuous cutting process ideal for high-volume manufacturing, while broaching creates splines by pushing or pulling a toothed tool through the workpiece, offering precise internal spline profiles for lower-volume or specialized applications.

Rotary tooling

Rotary hobbing uses a rotating hob to progressively cut gears with precise tooth profiles, while broaching employs a linear rotary tool to remove material in a single pass, making hobbing ideal for high-volume gear production and broaching better suited for internal keyways and splines.

Progressive cutting

Hobbing utilizes a progressive cutting process with continuous rotation to efficiently generate complex gear teeth, while broaching employs a linear progressive cut to produce precise, consistent internal or external profiles in a single pass.

Workpiece fixturing

Workpiece fixturing in hobbing requires precise rotational alignment and secure clamping to enable continuous gear cutting, whereas broaching fixturing demands rigid, linear positioning to maintain stability during the single-pass cutting operation.

hobbing vs broaching Infographic

njnir.com

njnir.com