Ductile iron offers superior elasticity and impact resistance compared to cast steel, making it ideal for applications requiring toughness and fatigue resistance. Cast steel provides higher tensile strength and better weldability, suitable for components subjected to extreme stress and complex shapes. Selecting between ductile iron and cast steel depends on balancing cost, mechanical properties, and intended application demands.

Table of Comparison

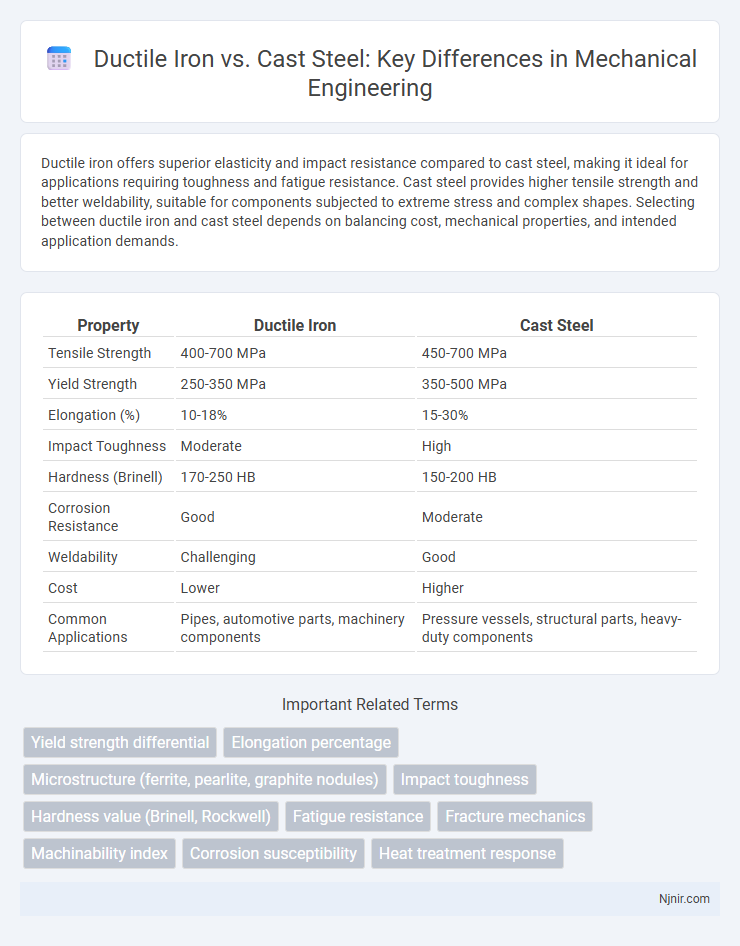

| Property | Ductile Iron | Cast Steel |

|---|---|---|

| Tensile Strength | 400-700 MPa | 450-700 MPa |

| Yield Strength | 250-350 MPa | 350-500 MPa |

| Elongation (%) | 10-18% | 15-30% |

| Impact Toughness | Moderate | High |

| Hardness (Brinell) | 170-250 HB | 150-200 HB |

| Corrosion Resistance | Good | Moderate |

| Weldability | Challenging | Good |

| Cost | Lower | Higher |

| Common Applications | Pipes, automotive parts, machinery components | Pressure vessels, structural parts, heavy-duty components |

Introduction to Ductile Iron and Cast Steel

Ductile iron, also known as nodular cast iron, features spherical graphite inclusions that enhance its toughness, ductility, and resistance to impact, making it suitable for automotive components and heavy machinery. Cast steel, characterized by its carbon content typically below 2%, offers superior strength, weldability, and machinability compared to cast iron, ideal for structural parts and pressure vessels. Both materials provide unique mechanical properties driven by their microstructures, influencing their application in various engineering sectors.

Chemical Composition Comparison

Ductile iron primarily contains carbon (3.0-3.6%) and silicon (1.8-2.8%) with added magnesium or cerium to promote graphite nodules, enhancing its ductility. Cast steel features a lower carbon content (typically 0.15-0.40%) and varies widely in alloying elements like manganese, chromium, and nickel to improve strength and toughness. The presence of spheroidal graphite in ductile iron differentiates it chemically and structurally from the more homogenous microstructure of cast steel.

Mechanical Properties and Performance

Ductile iron exhibits superior tensile strength and elongation due to its graphite nodules, providing excellent impact resistance and fatigue strength compared to cast steel, which generally offers higher hardness and better wear resistance. The microstructure of ductile iron enhances its ductility and toughness, making it ideal for applications requiring flexibility under stress, whereas cast steel's composition allows for higher yield strength and improved machinability. Performance-wise, ductile iron is preferred in automotive and pipeline industries for its cost-effective durability, while cast steel is chosen for heavy-duty machinery where extreme strength and abrasion resistance are critical.

Manufacturing Processes

Ductile iron is produced through a nodularization process by adding magnesium or cerium to molten iron, promoting spherical graphite formation, which enhances its strength and ductility. Cast steel manufacturing involves melting scrap steel or iron with alloying elements in electric arc or induction furnaces, followed by controlled solidification to achieve desired mechanical properties. The molten metal in both processes is poured into molds, but ductile iron requires precise nodulizer addition while cast steel demands stringent temperature control and alloy composition management for optimal microstructure development.

Microstructural Differences

Ductile iron features nodular graphite inclusions within its ferritic or pearlitic matrix, enhancing its toughness and ductility. Cast steel contains a more uniform microstructure of ferrite and pearlite without graphite, resulting in higher tensile strength and weldability. The nodularity in ductile iron cavities reduces stress concentration, whereas cast steel's grain structure provides consistent mechanical properties across applications.

Applications in Mechanical Engineering

Ductile iron is widely used in mechanical engineering for components requiring high strength, impact resistance, and ductility, such as gears, crankshafts, and suspension parts. Cast steel offers superior toughness and weldability, making it ideal for heavy-duty applications like pressure vessels, large machinery, and structural components subjected to dynamic loads. Both materials serve critical roles in mechanical design, with ductile iron preferred for wear resistance and cost-effectiveness, while cast steel excels in applications demanding higher fatigue strength and fabrication versatility.

Wear and Corrosion Resistance

Ductile iron exhibits superior wear resistance due to its graphite nodules that enhance toughness and reduce crack propagation, making it ideal for high-impact applications. Cast steel, while less resistant to wear, offers better corrosion resistance through alloying elements like chromium and nickel, which form protective oxide layers. Selection depends on the operational environment, balancing ductile iron's durability against cast steel's enhanced resistance to corrosive agents.

Cost and Economic Considerations

Ductile iron offers a lower initial material cost compared to cast steel, making it a more economical choice for large-scale production. Its superior machinability and reduced need for post-processing welding further decrease overall manufacturing expenses. Cast steel, while more expensive upfront, provides greater strength and toughness, potentially reducing long-term maintenance and replacement costs in demanding applications.

Design Flexibility and Machinability

Ductile iron offers superior design flexibility due to its excellent elongation and impact resistance, allowing engineers to create complex shapes and thinner sections without compromising strength. Cast steel, while providing higher tensile strength, often requires more precise control during machining processes because of its hardness and grain structure. Machinability of ductile iron is generally better, enabling faster production cycles and cost-effective manufacturing for intricate components.

Selection Criteria for Engineering Projects

Selection criteria for engineering projects prioritize ductile iron for its exceptional tensile strength, excellent wear resistance, and superior ductility, making it ideal for components subjected to dynamic loads and impact stress. Cast steel is often chosen for applications requiring higher toughness, weldability, and machinability, especially in large structures or heavy-duty machinery where customization and repair are crucial. Cost considerations, environmental conditions, and specific mechanical properties such as fatigue resistance and corrosion tolerance heavily influence the choice between ductile iron and cast steel in engineering designs.

Yield strength differential

Ductile iron typically exhibits a lower yield strength differential compared to cast steel, making it more resistant to deformation under varied stress conditions.

Elongation percentage

Ductile iron typically exhibits an elongation percentage of 10-25%, significantly higher than cast steel's 1-3%, indicating superior ductility and flexibility.

Microstructure (ferrite, pearlite, graphite nodules)

Ductile iron features a microstructure with spherical graphite nodules in a matrix of ferrite and pearlite, enhancing toughness and ductility, whereas cast steel typically contains a more uniform distribution of ferrite and pearlite without graphite nodules, resulting in higher strength but lower impact resistance.

Impact toughness

Ductile iron exhibits higher impact toughness than cast steel due to its nodular graphite structure, which enhances energy absorption and resistance to fracture under dynamic loads.

Hardness value (Brinell, Rockwell)

Ductile iron typically exhibits a Brinell hardness of 170-250 HB and Rockwell hardness of 70-100 HRB, while cast steel generally shows a broader hardness range from 120-250 HB and 20-60 HRC depending on heat treatment and alloy composition.

Fatigue resistance

Ductile iron exhibits superior fatigue resistance compared to cast steel due to its graphite nodules that impede crack propagation and enhance durability under cyclic loading.

Fracture mechanics

Ductile iron exhibits superior fracture toughness and crack resistance compared to cast steel, making it more reliable under cyclic loading and impact conditions in fracture mechanics applications.

Machinability index

Ductile iron typically exhibits a higher machinability index than cast steel due to its graphite nodules, which act as chip breakers and reduce tool wear.

Corrosion susceptibility

Ductile iron exhibits higher corrosion resistance than cast steel due to its graphite microstructure, which slows oxidation and enhances durability in harsh environments.

Heat treatment response

Ductile iron exhibits superior heat treatment response with enhanced ductility and toughness due to its graphite nodules, while cast steel offers more uniform hardness and strength but requires precise heat control to avoid brittleness.

ductile iron vs cast steel Infographic

njnir.com

njnir.com