SCADA systems excel in monitoring and controlling geographically dispersed assets through centralized data acquisition, offering flexibility for large-scale infrastructure like pipelines and power grids. DCS provides integrated process control with robust reliability and real-time automation suited for continuous manufacturing environments such as chemical plants and refineries. Choosing between SCADA and DCS depends on the scale, complexity, and specifics of the mechanical process requiring automation and control.

Table of Comparison

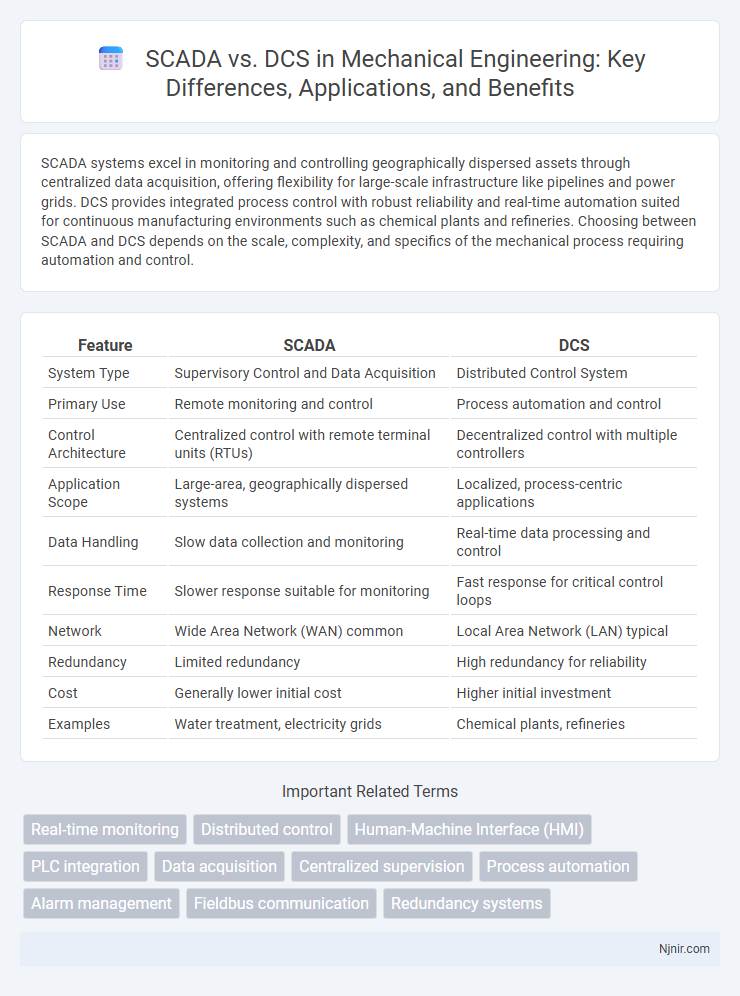

| Feature | SCADA | DCS |

|---|---|---|

| System Type | Supervisory Control and Data Acquisition | Distributed Control System |

| Primary Use | Remote monitoring and control | Process automation and control |

| Control Architecture | Centralized control with remote terminal units (RTUs) | Decentralized control with multiple controllers |

| Application Scope | Large-area, geographically dispersed systems | Localized, process-centric applications |

| Data Handling | Slow data collection and monitoring | Real-time data processing and control |

| Response Time | Slower response suitable for monitoring | Fast response for critical control loops |

| Network | Wide Area Network (WAN) common | Local Area Network (LAN) typical |

| Redundancy | Limited redundancy | High redundancy for reliability |

| Cost | Generally lower initial cost | Higher initial investment |

| Examples | Water treatment, electricity grids | Chemical plants, refineries |

Introduction to SCADA and DCS

SCADA (Supervisory Control and Data Acquisition) systems monitor and control large-scale industrial processes by collecting real-time data from remote locations for centralized supervision. DCS (Distributed Control Systems) manage production processes within localized areas by distributing control functions across interconnected controllers to enhance reliability and responsiveness. Both systems optimize process efficiency, with SCADA emphasizing wide-area monitoring and DCS focusing on localized process control.

Core Functions and Architecture

SCADA systems primarily focus on real-time monitoring and control of geographically dispersed assets through centralized data acquisition and supervisory control, using a hierarchical architecture with remote terminal units (RTUs) and programmable logic controllers (PLCs). DCS emphasizes integrated control of continuous processes within a single plant or facility, featuring distributed control elements connected via high-speed communication networks to enable precise process automation and reliability. The core SCADA architecture is designed for large-scale operations with remote monitoring, whereas DCS architecture supports localized, process-centric control with tighter integration and redundancy.

Key Components Comparison

SCADA systems primarily consist of remote terminal units (RTUs), programmable logic controllers (PLCs), human-machine interfaces (HMIs), and communication networks designed for real-time data acquisition and remote monitoring. DCS architecture integrates distributed controllers, operator workstations, engineering workstations, and field devices, enabling continuous process control and tighter control loops within localized areas. While SCADA emphasizes wide-area supervisory control with centralized monitoring, DCS focuses on modular control with decentralized execution for complex industrial processes.

Typical Applications in Mechanical Engineering

SCADA systems excel in monitoring and controlling large-scale mechanical engineering processes such as water treatment facilities, manufacturing plants, and HVAC systems, providing real-time data acquisition over wide geographic areas. DCS is typically preferred for precise control in complex mechanical engineering environments like chemical processing, power generation turbines, and continuous production lines due to its robust feedback loops and integrated control architecture. Both systems enable enhanced operational efficiency, but SCADA emphasizes supervisory control whereas DCS offers tighter process automation and control fidelity.

Scalability and Flexibility

SCADA systems offer high scalability by enabling easy integration of numerous remote devices and sensors across large geographical areas, making them ideal for distributed operations. DCS systems provide superior flexibility within localized control networks, allowing for complex process automation and seamless customization tailored to specific industrial processes. Both systems cater to different scalability and flexibility needs, with SCADA excelling in wide-area monitoring and DCS optimizing centralized control and real-time process adjustments.

Integration and Interoperability

SCADA systems excel in real-time data acquisition and remote monitoring, offering flexible integration with diverse third-party devices through open protocols like Modbus and OPC. DCS platforms provide seamless interoperability within process automation environments by tightly integrating controllers, HMI, and control algorithms under a unified architecture. Combining SCADA's broad data connectivity with DCS's robust process control allows optimized system integration for complex industrial applications.

Real-Time Monitoring and Control

SCADA systems excel in real-time monitoring by collecting data from geographically dispersed assets, enabling centralized control and remote supervisory functions across large-scale industrial operations. DCS offers advanced real-time control with rapid response capabilities, integrating control loops and process automation within localized plants to maintain precise process variables. Both systems leverage real-time data acquisition, but SCADA prioritizes wide-area visualization while DCS focuses on closed-loop control for optimized manufacturing processes.

Data Acquisition and Management

SCADA systems excel in real-time data acquisition from geographically dispersed assets, providing centralized monitoring and control through HMIs. DCS platforms integrate data acquisition with process automation, offering seamless management and control of continuous, complex processes within a localized environment. Effective data management in SCADA emphasizes alarm handling and event logging, while DCS prioritizes process optimization with integrated data analytics and control loops.

Security and Reliability Features

SCADA systems prioritize real-time data acquisition and remote monitoring but face higher cybersecurity risks due to their extensive network connectivity and legacy protocols, requiring robust encryption and intrusion detection measures to enhance security. DCS systems offer greater reliability with tightly integrated control loops and localized processing, reducing vulnerability to network disruptions and enabling advanced fault-tolerant architectures. Enhanced security features in modern DCS include role-based access control and secure communication channels, making them preferable for critical industrial processes demanding both safety and continuous operation.

Cost Considerations and ROI

SCADA systems typically offer lower initial costs and greater flexibility for small to medium-scale operations, making them cost-effective for geographically dispersed processes. DCS solutions involve higher upfront investment due to integrated hardware and software tailored for complex, large-scale industrial automation, but deliver superior reliability and scalability that enhance long-term ROI. Evaluating total cost of ownership (TCO) and potential productivity gains is critical when choosing between SCADA and DCS for maximizing financial returns.

Real-time monitoring

SCADA systems provide real-time monitoring for geographically dispersed assets by collecting data from remote devices, while DCS offers real-time control and monitoring concentrated within a localized industrial process.

Distributed control

Distributed control in DCS provides integrated, real-time process management across multiple sites, while SCADA systems primarily offer remote monitoring with less emphasis on centralized control.

Human-Machine Interface (HMI)

SCADA systems offer centralized Human-Machine Interface (HMI) panels for real-time remote monitoring and control across dispersed assets, while DCS provides integrated, localized HMI solutions optimized for continuous process automation and complex industrial environments.

PLC integration

SCADA systems offer flexible PLC integration for remote monitoring and control, while DCS provides seamless PLC connectivity within centralized process automation for enhanced reliability and real-time data management.

Data acquisition

SCADA systems excel in remote data acquisition for geographically dispersed assets, while DCS provides centralized, real-time data acquisition optimized for continuous process control within single facilities.

Centralized supervision

SCADA systems provide centralized supervision primarily for wide-area industrial processes with remote monitoring, while DCS offers centralized supervision focused on localized, continuous control within manufacturing plants.

Process automation

SCADA systems excel in remote monitoring and data acquisition for large-scale distributed processes, while DCS offers integrated, real-time control and automation of complex, continuous industrial processes within centralized facilities.

Alarm management

SCADA systems offer centralized real-time alarm monitoring for wide-area processes, while DCS provides integrated, high-speed alarm management within localized industrial control environments for enhanced operational safety.

Fieldbus communication

SCADA systems typically use standard protocols like Modbus or DNP3 for Fieldbus communication, whereas DCS primarily relies on proprietary Fieldbus protocols such as FOUNDATION Fieldbus or PROFIBUS for real-time process control and automation.

Redundancy systems

SCADA systems typically offer limited redundancy through network and server duplication, whereas DCS systems provide comprehensive redundancy at the controller, communication, and power supply levels to ensure continuous process control.

SCADA vs DCS Infographic

njnir.com

njnir.com