Universal joints allow torque transmission between shafts with varying angles but can cause vibration and speed fluctuations at high angles. CV joints maintain constant velocity and smooth power transfer even at significant angles, making them ideal for front-wheel-drive vehicles. Understanding the differences in durability and application helps select the appropriate joint for specific mechanical systems.

Table of Comparison

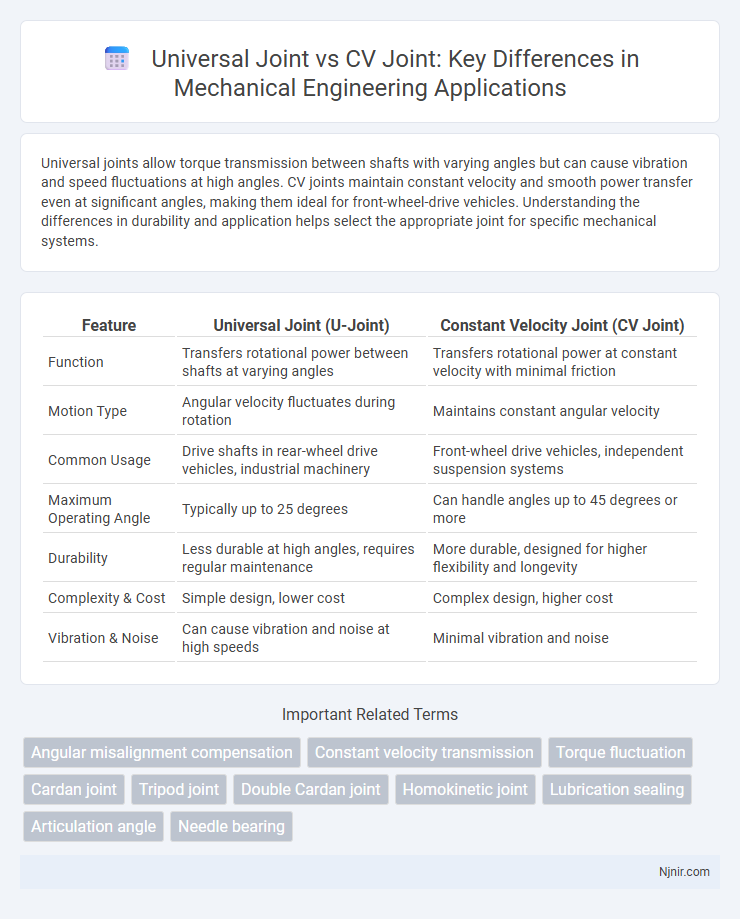

| Feature | Universal Joint (U-Joint) | Constant Velocity Joint (CV Joint) |

|---|---|---|

| Function | Transfers rotational power between shafts at varying angles | Transfers rotational power at constant velocity with minimal friction |

| Motion Type | Angular velocity fluctuates during rotation | Maintains constant angular velocity |

| Common Usage | Drive shafts in rear-wheel drive vehicles, industrial machinery | Front-wheel drive vehicles, independent suspension systems |

| Maximum Operating Angle | Typically up to 25 degrees | Can handle angles up to 45 degrees or more |

| Durability | Less durable at high angles, requires regular maintenance | More durable, designed for higher flexibility and longevity |

| Complexity & Cost | Simple design, lower cost | Complex design, higher cost |

| Vibration & Noise | Can cause vibration and noise at high speeds | Minimal vibration and noise |

Introduction to Universal Joints and CV Joints

Universal joints, also known as U-joints, are mechanical components used to transmit rotary motion between two shafts at varying angles, commonly found in drive shafts of rear-wheel drive vehicles. Constant velocity (CV) joints enable smooth power transmission at a constant rotational speed despite varying shaft angles, predominantly used in front-wheel drive and all-wheel drive vehicles. Both joints accommodate angular misalignment but differ in design and applications, with CV joints offering superior flexibility and reduced vibration compared to traditional universal joints.

Fundamental Working Principles

Universal joints transmit rotational power between shafts at varying angles using a cross-shaped pivot, allowing for angular flex but causing speed fluctuations during rotation. CV (Constant Velocity) joints maintain a constant rotational speed regardless of the shaft angle by using a design that accommodates axial and angular movement, reducing vibration and allowing smoother power transfer. The fundamental difference lies in the universal joint's ability to handle angular misalignment with variable velocity and the CV joint's precision in delivering constant velocity at different angles.

Key Design Differences

Universal joints (U-joints) use a cross-shaped pivot to transfer torque between shafts at varying angles, typically allowing angular misalignment up to 45 degrees but causing speed fluctuations. Constant velocity (CV) joints employ precision bearings and a cage assembly to maintain uniform rotational speed while accommodating larger steering angles and smoother power delivery. CV joints are often encased in protective boots to prevent contamination, while U-joints rely on lubrication for durability in less complex mechanical environments.

Performance in Angular Flexibility

Universal joints provide robust angular flexibility capable of handling high torque but experience speed variations and vibrations at larger angles, limiting smooth performance. CV joints excel in maintaining constant rotational speed regardless of the angle, offering superior smoothness and efficiency in applications with significant steering or suspension movement. Their advanced design allows CV joints to perform better in dynamic conditions with varying angular demands.

Torque Transmission Capabilities

Universal joints and CV joints differ significantly in torque transmission capabilities, with CV joints providing smoother torque delivery and consistent angular velocity, especially in high-angle applications. Universal joints can transmit high torque but may cause fluctuations in rotational speed and increased vibration at larger angles. CV joints maintain efficient torque transmission across varying steering and suspension movements, making them ideal for front-wheel-drive vehicles.

Durability and Maintenance Requirements

Universal joints (U-joints) generally require more frequent maintenance due to their exposure to wear and need for regular lubrication, impacting their overall durability. Constant velocity (CV) joints feature a sealed design that protects internal components from dirt and moisture, significantly enhancing their longevity and reducing maintenance demands. The improved durability and lower upkeep of CV joints make them preferable for front-wheel-drive vehicles and applications requiring smooth power transmission under variable angles.

Typical Applications in Mechanical Systems

Universal joints are commonly used in applications requiring the transmission of rotary motion between shafts at varying angles, such as in vehicle drive shafts and industrial machinery. CV (constant velocity) joints are typically employed in front-wheel-drive vehicles and robotic systems where maintaining a constant rotational speed at different angles is crucial. Mechanical systems involving smooth power transfer and reduced vibration often prefer CV joints for their efficiency and durability.

Advantages and Disadvantages

Universal joints offer simplicity and durability, performing well in low-speed, high-torque applications, but they suffer from non-constant velocity which can cause vibrations. CV joints provide smooth power transfer at varying angles and high speeds, ensuring reduced wear and improved handling, though they are more complex and expensive to manufacture. Maintenance is critical for CV joints to avoid boot damage and grease leakage, whereas universal joints require less frequent servicing but may not handle sharp angles as effectively.

Cost Considerations and Availability

Universal joints (U-joints) generally cost less than constant velocity (CV) joints due to simpler design and manufacturing processes, making them an economical choice for many rear-wheel drive and heavy-duty vehicles. CV joints, while more expensive upfront, provide smoother power delivery and durability in front-wheel drive and all-wheel drive systems, which often justifies their higher price for these applications. Availability of U-joints is widespread in aftermarket parts stores and repair shops, whereas CV joints may require sourcing from specialized suppliers or OEM dealers, potentially increasing maintenance costs.

Summary: Choosing Between Universal and CV Joints

Universal joints (U-joints) offer cost-effective, simple designs ideal for applications with moderate angular movement, while CV joints provide smoother power transmission and consistent velocity at varying angles, making them preferable for front-wheel-drive vehicles. CV joints maintain constant rotational speed and reduce vibration, enhancing driving comfort and durability under high-stress conditions. Selecting between U-joints and CV joints depends on the vehicle's drivetrain configuration, required performance, and operational angles.

Angular misalignment compensation

Universal joints effectively accommodate angular misalignment up to approximately 45 degrees but cause speed fluctuations, whereas CV joints maintain constant velocity and smooth torque transmission across similar or greater angular misalignments, typically up to 50 degrees.

Constant velocity transmission

CV joints provide constant velocity transmission by maintaining uniform rotational speed regardless of the joint angle, unlike universal joints which cause speed fluctuations.

Torque fluctuation

Universal joints exhibit significant torque fluctuation at higher operating angles, while CV joints maintain smooth torque delivery with minimal fluctuation across a wide range of angles.

Cardan joint

The Cardan joint, a type of universal joint, transmits torque between misaligned shafts with simple construction, while CV joints maintain constant velocity and accommodate complex angles for smoother power delivery in front-wheel-drive vehicles.

Tripod joint

Tripod joints, a type of constant velocity (CV) joint, provide smooth power transmission with low friction and reduced vibration compared to traditional universal joints, making them ideal for front-wheel-drive vehicles.

Double Cardan joint

The Double Cardan joint, a specialized type of universal joint, provides smoother power transmission and greater angular flexibility compared to a standard universal joint, making it more effective than CV joints in handling high torque and misalignment in driveline applications.

Homokinetic joint

The Homokinetic joint, also known as the CV joint, provides constant rotational velocity and smooth power transmission in front-wheel-drive vehicles, unlike a universal joint which allows angular movement but with variable velocity.

Lubrication sealing

Universal joints rely on grease lubrication sealed by rubber boots to prevent contamination, whereas CV joints use advanced grease sealed within flexible, durable rubber or plastic boots to maintain optimal lubrication and protect against dirt and moisture.

Articulation angle

Universal joints typically allow articulation angles up to 25-30 degrees, while CV joints efficiently handle higher articulation angles up to 45 degrees with smoother rotational motion.

Needle bearing

Universal joints typically use needle bearings to accommodate angular misalignment and transmit torque efficiently, while CV joints employ needle bearings within their bearings to allow smooth rotational movement and maintain constant velocity at varying angles.

universal joint vs CV joint Infographic

njnir.com

njnir.com