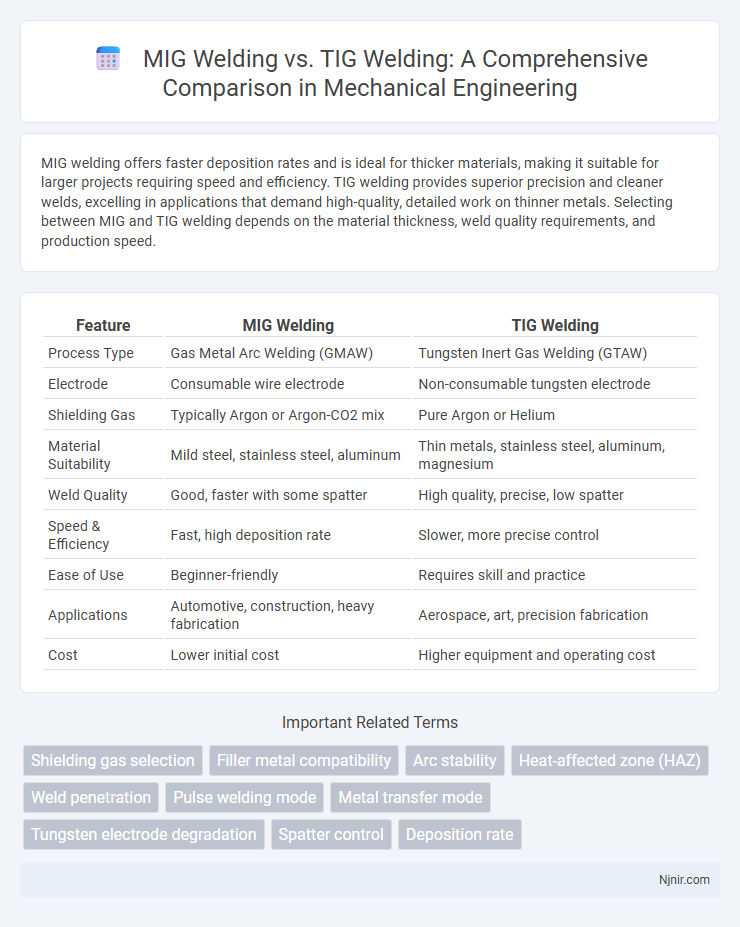

MIG welding offers faster deposition rates and is ideal for thicker materials, making it suitable for larger projects requiring speed and efficiency. TIG welding provides superior precision and cleaner welds, excelling in applications that demand high-quality, detailed work on thinner metals. Selecting between MIG and TIG welding depends on the material thickness, weld quality requirements, and production speed.

Table of Comparison

| Feature | MIG Welding | TIG Welding |

|---|---|---|

| Process Type | Gas Metal Arc Welding (GMAW) | Tungsten Inert Gas Welding (GTAW) |

| Electrode | Consumable wire electrode | Non-consumable tungsten electrode |

| Shielding Gas | Typically Argon or Argon-CO2 mix | Pure Argon or Helium |

| Material Suitability | Mild steel, stainless steel, aluminum | Thin metals, stainless steel, aluminum, magnesium |

| Weld Quality | Good, faster with some spatter | High quality, precise, low spatter |

| Speed & Efficiency | Fast, high deposition rate | Slower, more precise control |

| Ease of Use | Beginner-friendly | Requires skill and practice |

| Applications | Automotive, construction, heavy fabrication | Aerospace, art, precision fabrication |

| Cost | Lower initial cost | Higher equipment and operating cost |

Introduction to MIG and TIG Welding

MIG welding (Metal Inert Gas) uses a continuous solid wire electrode fed through a welding gun, creating a strong, fast weld primarily suited for thick materials like steel and aluminum. TIG welding (Tungsten Inert Gas) employs a non-consumable tungsten electrode to produce precise, high-quality welds, ideal for thinner metals and intricate designs. Both methods utilize inert gas shielding to protect welds from contamination, but MIG excels in speed while TIG offers superior control and finish.

Fundamental Differences Between MIG and TIG Welding

MIG welding uses a continuous wire electrode fed through a welding gun and shielded by inert gas, making it faster and easier for thicker materials. TIG welding employs a non-consumable tungsten electrode with a separate filler rod, offering superior precision and control ideal for thin or intricate metal work. The core differences lie in electrode type, speed, and application complexity, influencing their suitability for diverse welding projects.

Equipment and Setup Comparison

MIG welding requires a wire feeder, a welding gun, and a shielding gas supply, offering faster setup and easier operation with less precise equipment calibration. TIG welding needs a tungsten electrode, a torch with a gas lens, and often a foot pedal for current control, demanding a more complex setup and meticulous adjustments. The TIG process requires high-quality, specialized equipment for precision and cleaner welds, whereas MIG welding benefits from simpler, more versatile gear suitable for quicker production tasks.

Material Compatibility and Applications

MIG welding excels in joining thicker, mild steel and stainless steel materials due to its fast deposition rate and ease of use, making it ideal for automotive repair and heavy fabrication. TIG welding offers superior precision and control, enabling high-quality welds on thin metals such as aluminum, magnesium, and non-ferrous alloys, commonly used in aerospace and medical device manufacturing. Material compatibility dictates the choice between MIG's efficiency for general-purpose metal joining and TIG's specialized application for delicate, corrosion-resistant, or high-strength weld requirements.

Welding Speed and Efficiency

MIG welding offers significantly higher welding speeds compared to TIG welding, making it ideal for projects requiring fast material deposition and minimal downtime. The continuous wire feed in MIG welding enhances efficiency by reducing stop-and-start interruptions, while TIG welding excels in precision but requires slower, more controlled manual feeding. For large-scale or production welding, MIG's speed and automation provide superior efficiency, whereas TIG is preferred for detailed, high-quality welds despite its slower pace.

Quality and Strength of Welds

MIG welding produces strong, durable welds ideal for thick materials and high-speed applications, offering excellent penetration and consistent bead quality. TIG welding excels in delivering superior quality welds with precise control, resulting in cleaner, aesthetically pleasing joints with minimal spatter, ideal for thin metals and critical projects. While MIG is favored for speed and strength in heavy-duty tasks, TIG provides unmatched precision and weld integrity, critical for aerospace and automotive industries.

Skill Level and Learning Curve

MIG welding offers a shorter learning curve and requires less skill, making it ideal for beginners due to its ease of use and faster welding speed. TIG welding demands a higher skill level, requiring precise control of heat and filler material, which results in a steeper learning curve for mastery. Professionals often prefer TIG welding for its ability to produce cleaner, high-quality welds on thin materials and intricate projects.

Cost Analysis: MIG vs TIG Welding

MIG welding generally offers lower operational costs due to faster welding speeds and less technique sensitivity, reducing labor expenses and enabling higher productivity for large-scale projects. TIG welding, while providing superior precision and cleaner welds, incurs higher costs from slower welding speeds, increased skill requirements, and more expensive equipment and consumables like tungsten electrodes and inert gases. For budget-conscious applications prioritizing speed and efficiency, MIG welding typically represents a more cost-effective choice, whereas TIG welding justifies its expense in scenarios demanding fine detail and high-quality finishes.

Safety Considerations in MIG and TIG Welding

MIG welding requires robust ventilation systems to manage the high levels of shielding gases and fumes produced, while TIG welding emits fewer fumes but demands more attention to ultraviolet light exposure due to the intense arc. Both methods necessitate comprehensive personal protective equipment, including flame-resistant clothing, welding helmets with appropriate lens shades, and gloves to prevent burns and eye injuries. Proper training on equipment handling and workspace organization is essential to minimize risks such as electric shock, fire hazards, and exposure to harmful radiation in both MIG and TIG welding processes.

Choosing the Right Welding Process for Your Project

MIG welding offers faster weld times and is ideal for thicker materials and production work, providing ease of use for beginners and high deposition rates. TIG welding excels in precision and control, making it perfect for thin metals, detailed projects, and high-quality welds that require a clean finish. Evaluating material type, project complexity, and desired weld quality helps determine whether MIG's efficiency or TIG's precision best suits your welding needs.

Shielding gas selection

MIG welding typically uses argon mixed with carbon dioxide as the shielding gas for better arc stability and penetration, while TIG welding primarily requires pure argon to ensure precise weld quality and minimal contamination.

Filler metal compatibility

MIG welding offers broader filler metal compatibility with various wire types like steel, aluminum, and stainless steel, while TIG welding provides precise control primarily for thin materials using specialized filler rods such as ER70S-2 for steel and ER4043 for aluminum.

Arc stability

MIG welding offers superior arc stability with continuous wire feed and easier control, while TIG welding provides precise but less stable arcs requiring skilled manual operation.

Heat-affected zone (HAZ)

MIG welding produces a larger heat-affected zone (HAZ) with faster cooling rates, while TIG welding creates a smaller, more controlled HAZ, resulting in less thermal distortion and better precision.

Weld penetration

MIG welding typically offers faster welding speeds with moderate weld penetration, while TIG welding provides superior weld penetration and precision, making it ideal for thinner metals and critical joints.

Pulse welding mode

Pulse welding mode in MIG welding offers faster deposition rates and easier handling of thicker materials, while TIG pulse welding provides superior precision and control for thinner metals and intricate welds.

Metal transfer mode

MIG welding utilizes a short-circuit or spray metal transfer mode for higher deposition rates, while TIG welding employs a non-consumable tungsten electrode with no metal transfer, offering precise control and superior weld quality.

Tungsten electrode degradation

TIG welding experiences slower tungsten electrode degradation compared to MIG welding due to its non-consumable electrode design and stable arc characteristics.

Spatter control

MIG welding typically produces more spatter than TIG welding, which offers superior spatter control due to its precise heat control and non-consumable tungsten electrode.

Deposition rate

MIG welding offers a higher deposition rate than TIG welding, making it more efficient for thicker materials and faster production.

MIG welding vs TIG welding Infographic

njnir.com

njnir.com