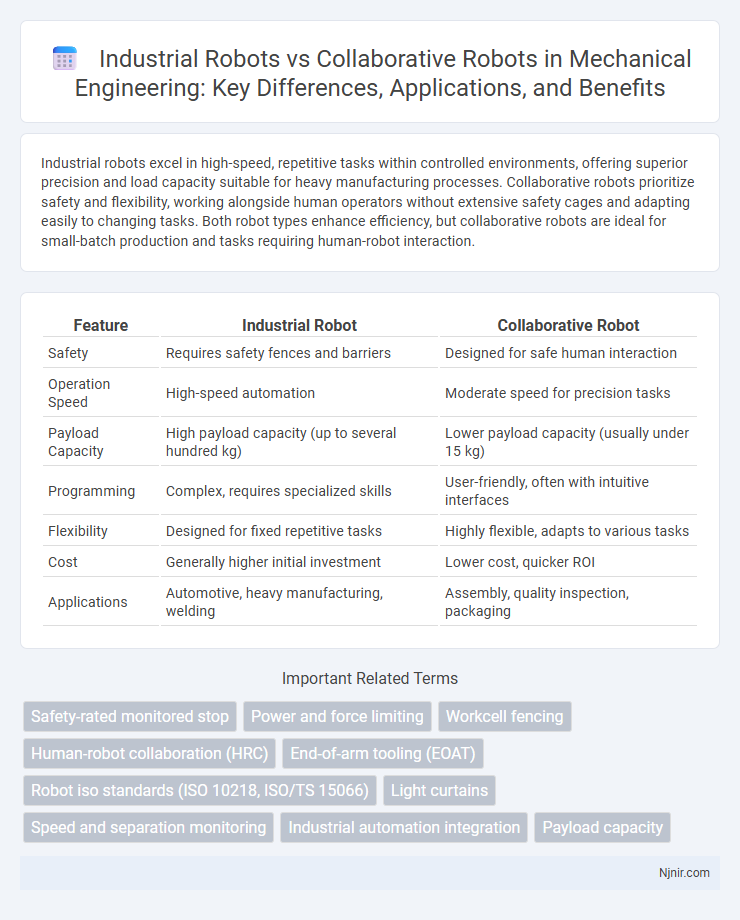

Industrial robots excel in high-speed, repetitive tasks within controlled environments, offering superior precision and load capacity suitable for heavy manufacturing processes. Collaborative robots prioritize safety and flexibility, working alongside human operators without extensive safety cages and adapting easily to changing tasks. Both robot types enhance efficiency, but collaborative robots are ideal for small-batch production and tasks requiring human-robot interaction.

Table of Comparison

| Feature | Industrial Robot | Collaborative Robot |

|---|---|---|

| Safety | Requires safety fences and barriers | Designed for safe human interaction |

| Operation Speed | High-speed automation | Moderate speed for precision tasks |

| Payload Capacity | High payload capacity (up to several hundred kg) | Lower payload capacity (usually under 15 kg) |

| Programming | Complex, requires specialized skills | User-friendly, often with intuitive interfaces |

| Flexibility | Designed for fixed repetitive tasks | Highly flexible, adapts to various tasks |

| Cost | Generally higher initial investment | Lower cost, quicker ROI |

| Applications | Automotive, heavy manufacturing, welding | Assembly, quality inspection, packaging |

Introduction to Industrial and Collaborative Robots

Industrial robots are automated machines designed for high-speed, repetitive tasks in manufacturing environments, often requiring safety barriers due to their powerful, precise movements. Collaborative robots, or cobots, are engineered to work alongside human operators, featuring advanced sensors and safety mechanisms to enable direct interaction without protective fencing. Both types enhance productivity but differ significantly in flexibility, application scope, and integration within human workspaces.

Key Differences Between Industrial and Collaborative Robots

Industrial robots operate in segregated environments, designed for high-speed, repetitive tasks requiring precision and strength, often handling heavy loads or hazardous materials. Collaborative robots, or cobots, work alongside humans safely without extensive safety barriers, featuring sensors and force-limited joints to detect and prevent collisions. The primary differences lie in their applications, safety features, flexibility, and ease of programming, with industrial robots excelling in large-scale production and cobots enhancing human-robot interaction in flexible manufacturing settings.

Safety Features and Human Interaction

Industrial robots feature advanced safety mechanisms such as safety fences, emergency stop buttons, and light curtains to prevent accidental human contact in high-speed, heavy-duty operations. Collaborative robots (cobots) integrate sensors, force limiters, and real-time monitoring to ensure safe interaction by stopping or slowing down upon detecting human presence, enabling shared workspaces without physical barriers. The ergonomic design and compliant control systems of cobots reduce injury risks and enhance seamless human-robot collaboration in manufacturing environments.

Payload and Performance Capabilities

Industrial robots typically offer higher payload capacities ranging from 100 kg to several tons, enabling them to perform heavy-duty tasks in automotive and manufacturing industries with precise, high-speed movements exceeding 1000 mm/s. Collaborative robots (cobots) are designed with lower payload capacities, generally between 3 kg and 20 kg, prioritizing safety features and flexibility for interaction with human operators, which may limit their speed and precision compared to industrial robots. Performance capabilities of industrial robots include sustained operation in harsh environments with minimal downtime, while cobots excel in adaptability and ease of programming, making them ideal for small-scale assembly and customized production processes.

Integration and Flexibility in Manufacturing

Industrial robots offer high precision and speed but require complex integration with safety barriers and dedicated programming, limiting flexibility in manufacturing environments. Collaborative robots (cobots) feature easier integration with existing workflows due to advanced sensor technologies and user-friendly interfaces, enabling rapid redeployment for varied tasks. The flexibility of cobots supports dynamic production lines and small-batch customization, enhancing adaptability compared to traditional industrial robots.

Cost Analysis and Return on Investment

Industrial robots typically require higher initial capital investment, averaging $50,000 to $150,000 per unit, but deliver significant long-term productivity gains in high-volume manufacturing. Collaborative robots (cobots) cost between $20,000 and $50,000, offering faster deployment and lower integration expenses, which accelerates return on investment (ROI) in flexible production environments. ROI for industrial robots is maximized through continuous operation in repetitive tasks, whereas cobots provide quicker payback by enabling human-robot cooperation and reducing labor costs in variable workflows.

Applications in Mechanical Engineering

Industrial robots in mechanical engineering excel at high-speed, repetitive tasks such as welding, machining, and assembly lines, offering precision and endurance in hazardous environments. Collaborative robots (cobots) enhance flexibility by working safely alongside human operators, ideal for tasks like small parts assembly, quality inspection, and machine tending where adaptability and human-robot interaction are critical. The integration of collaborative robots reduces downtime and boosts productivity in customized manufacturing processes compared to traditional industrial robots.

Programming and Ease of Use

Industrial robots require complex programming with specialized languages like RAPID or KUKA KRL, demanding skilled operators and significant setup time. Collaborative robots (cobots) feature intuitive programming interfaces, often using hand-guiding or graphical user interfaces, enabling fast deployment and ease of use by non-experts. Cobots enhance flexibility in manufacturing environments by reducing programming complexity and minimizing downtime.

Maintenance and Operational Lifespan

Industrial robots require regular, intensive maintenance to ensure optimal performance, often involving specialized technicians and scheduled downtime, which can impact operational efficiency. Collaborative robots (cobots) typically demand less frequent maintenance due to their simpler design and built-in safety features, enabling seamless integration alongside human workers without extensive interruptions. The operational lifespan of industrial robots generally exceeds that of cobots, with robust components designed for heavy-duty tasks, while cobots prioritize flexibility and ease of use over longevity.

Future Trends in Robotics for Mechanical Engineering

Industrial robots are evolving with enhanced precision and high-speed automation, primarily designed for repetitive, heavy-duty tasks in manufacturing environments. Collaborative robots (cobots) are increasingly integrated with AI and sensor technologies, enabling safe interaction with human workers and flexible deployment in assembly lines and quality control. Future trends emphasize hybrid systems combining industrial robots' strength and cobots' adaptability, driving advancements in smart factories and Industry 4.0 within mechanical engineering.

Safety-rated monitored stop

Safety-rated monitored stop in collaborative robots enables immediate halting of operations when a human enters the workspace, unlike traditional industrial robots that rely on physical barriers for hazard prevention.

Power and force limiting

Collaborative robots utilize power and force limiting technology to ensure safe human interaction, whereas industrial robots operate with higher power and force requiring safety barriers to prevent accidents.

Workcell fencing

Industrial robots require workcell fencing for safety due to high-speed, high-force operations, while collaborative robots operate without fencing, enabling direct human-robot interaction with built-in sensors and safety features.

Human-robot collaboration (HRC)

Collaborative robots (cobots) are specifically designed for Human-Robot Collaboration (HRC) with advanced safety features and intuitive interfaces, whereas traditional industrial robots prioritize high-speed automation but require safety barriers to separate humans.

End-of-arm tooling (EOAT)

Industrial robots use rigid, high-precision End-of-Arm Tooling (EOAT) for heavy-duty tasks, while collaborative robots employ flexible, lightweight EOAT designed for safe human interaction and adaptability.

Robot iso standards (ISO 10218, ISO/TS 15066)

Industrial robots follow ISO 10218 standards for safety and design, while collaborative robots are guided by both ISO 10218 and ISO/TS 15066, which specifically address safe human-robot interaction and risk assessment.

Light curtains

Industrial robots typically require light curtains for high-speed safety barriers, whereas collaborative robots integrate advanced sensor-based light curtains enabling safe human-robot interaction without physical barriers.

Speed and separation monitoring

Industrial robots prioritize high-speed operation with physical safety barriers, while collaborative robots use slower speeds combined with advanced separation monitoring sensors to ensure safe human interaction.

Industrial automation integration

Industrial robots deliver high-speed, high-precision tasks in industrial automation integration, while collaborative robots enhance flexibility and safety by working alongside human operators.

Payload capacity

Industrial robots typically have a higher payload capacity ranging from 50 to over 1,000 kilograms, whereas collaborative robots usually handle lighter payloads between 3 to 20 kilograms to ensure safe human interaction.

Industrial robot vs collaborative robot Infographic

njnir.com

njnir.com