Eddy current brakes offer a wear-free, maintenance-reducing alternative to traditional friction brakes by using electromagnetic forces to generate resistance and slow down mechanical systems. Unlike friction brakes, which rely on physical contact and produce heat and wear, eddy current brakes provide smooth, consistent deceleration without mechanical degradation. This results in higher reliability and longer service life, especially in high-speed or heavy-duty applications.

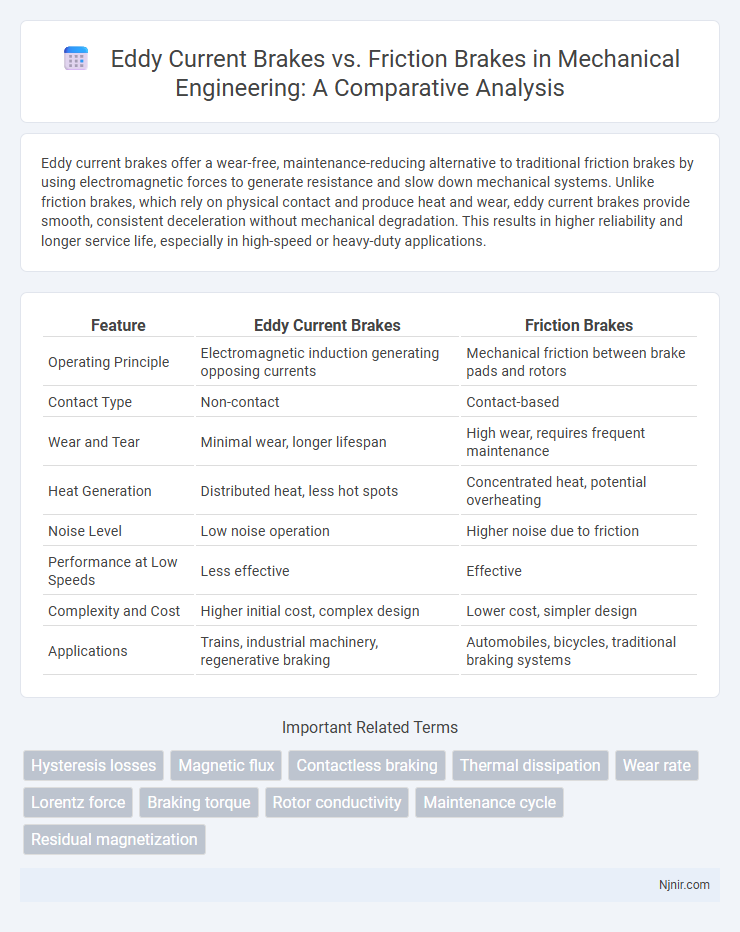

Table of Comparison

| Feature | Eddy Current Brakes | Friction Brakes |

|---|---|---|

| Operating Principle | Electromagnetic induction generating opposing currents | Mechanical friction between brake pads and rotors |

| Contact Type | Non-contact | Contact-based |

| Wear and Tear | Minimal wear, longer lifespan | High wear, requires frequent maintenance |

| Heat Generation | Distributed heat, less hot spots | Concentrated heat, potential overheating |

| Noise Level | Low noise operation | Higher noise due to friction |

| Performance at Low Speeds | Less effective | Effective |

| Complexity and Cost | Higher initial cost, complex design | Lower cost, simpler design |

| Applications | Trains, industrial machinery, regenerative braking | Automobiles, bicycles, traditional braking systems |

Introduction to Braking Systems in Mechanical Engineering

Eddy current brakes utilize electromagnetic fields to induce currents in a conductor, producing resistance without physical contact, resulting in reduced wear and maintenance compared to traditional friction brakes. Friction brakes generate stopping force through mechanical contact between pads and rotors, providing reliable, high-friction torque essential for rapid deceleration in diverse mechanical systems. In mechanical engineering, understanding the distinct mechanisms, efficiency, and application scenarios of eddy current and friction brakes is crucial for optimizing braking system design and performance.

Fundamental Principles of Eddy Current Brakes

Eddy current brakes operate based on electromagnetic induction, where a magnetic field generates circulating currents (eddy currents) in a conductive material, producing resistive forces that slow motion without physical contact. This non-contact braking mechanism reduces wear and maintenance compared to traditional friction brakes, which rely on direct contact between brake pads and rotors to create frictional force. The efficiency and durability of eddy current brakes make them ideal for applications requiring smooth, consistent deceleration and minimal mechanical degradation.

Working Mechanism of Friction Brakes

Friction brakes operate by converting kinetic energy into heat through the contact between brake pads and a spinning disc or drum, creating resistance that slows or stops the vehicle. The system relies on the frictional force generated when the brake pads clamp onto the rotating surface, effectively reducing speed via mechanical abrasion. Unlike eddy current brakes, which use electromagnetic forces, friction brakes depend on physical contact and wear for their braking action.

Key Differences Between Eddy Current and Friction Brakes

Eddy current brakes use magnetic fields to induce currents that generate resistance without physical contact, resulting in minimal wear and maintenance, while friction brakes rely on mechanical contact between brake pads and rotors, leading to wear and the need for regular replacement. Eddy current brakes provide smoother, quieter deceleration and are highly effective at high speeds, whereas friction brakes offer stronger stopping power at low speeds and emergency stops. The energy in eddy current braking is dissipated as heat in the conductor, but without surface wear, contrasting with friction brakes where energy converts to heat through pad-to-rotor friction, causing material degradation.

Advantages of Eddy Current Brakes

Eddy current brakes offer superior durability and low maintenance due to the absence of physical contact and friction wear, resulting in longer operational life. They provide smooth, silent, and efficient braking performance, especially at high speeds, by converting kinetic energy into heat through electromagnetic induction. Their precise control and rapid response make them ideal for applications requiring consistent, wear-free deceleration without replacement of brake pads or discs.

Advantages of Friction Brakes

Friction brakes offer superior stopping power through direct contact between brake pads and rotors, providing reliable deceleration in a wide range of conditions. They are cost-effective, easier to maintain, and widely available compared to eddy current brakes. Their performance remains consistent regardless of temperature or speed, making friction brakes ideal for various automotive and industrial applications.

Limitations and Challenges of Eddy Current Braking

Eddy current brakes face limitations including reduced effectiveness at low speeds due to decreased relative motion between the conductor and magnetic field, which diminishes the induced currents responsible for braking force. They generate heat within the conductive components, necessitating robust thermal management systems to prevent material degradation and ensure consistent performance. High system costs and weight, along with the requirement for non-ferromagnetic materials to avoid magnetic interference, pose challenges for widespread adoption compared to traditional friction brakes.

Maintenance Requirements: Eddy Current vs Friction Brakes

Eddy current brakes require minimal maintenance due to the absence of physical contact and wear components, reducing downtime and operational costs. Friction brakes demand regular inspection and replacement of brake pads or linings caused by wear from constant mechanical contact. The maintenance requirements for eddy current brakes are significantly lower, enhancing reliability and longevity in applications where frequent braking is necessary.

Typical Applications in Industry and Transport

Eddy current brakes are commonly used in applications requiring non-contact, wear-free deceleration such as in high-speed trains, roller coasters, and industrial machinery like cranes and conveyors where smooth, precise control is essential. Friction brakes dominate in automotive vehicles, heavy trucks, and bicycles due to their cost-effectiveness, strong stopping power, and ease of maintenance despite wear and heat generation. Industries favor eddy current brakes for continuous operation environments, while friction brakes are preferred in scenarios demanding high torque and rapid response.

Future Trends and Innovations in Braking Technology

Eddy current brakes are advancing with the integration of smart sensors and AI for adaptive braking control, offering reduced wear and enhanced efficiency compared to traditional friction brakes. Innovations in high-temperature superconducting materials promise to amplify the braking force and energy recovery potential of eddy current systems. Meanwhile, friction brakes are evolving with advanced composite materials to improve heat dissipation and durability, but the shift towards contactless technologies like eddy current brakes may redefine the future landscape of braking solutions.

Hysteresis losses

Eddy current brakes generate lower hysteresis losses compared to friction brakes, enhancing efficiency by minimizing energy dissipation during magnetic field reversal in conductive materials.

Magnetic flux

Eddy current brakes utilize magnetic flux to generate opposing currents that produce non-contact braking force, whereas friction brakes rely on physical contact between brake pads and rotors to create stopping power.

Contactless braking

Eddy current brakes provide contactless braking by using electromagnetic forces to generate resistance without physical contact, reducing wear and maintenance compared to traditional friction brakes.

Thermal dissipation

Eddy current brakes dissipate heat through electromagnetic induction without physical contact, reducing thermal wear compared to friction brakes that convert kinetic energy into heat via surface friction, often leading to higher localized thermal stress and wear.

Wear rate

Eddy current brakes exhibit significantly lower wear rates compared to friction brakes due to their non-contact electromagnetic braking mechanism.

Lorentz force

Eddy current brakes use Lorentz force to generate resistance without contact by inducing currents in conductive materials, whereas friction brakes rely on direct mechanical friction for stopping power.

Braking torque

Eddy current brakes generate braking torque through electromagnetic induction without physical contact, resulting in consistent, maintenance-free torque output, whereas friction brakes produce braking torque via mechanical contact, subject to wear and variable performance.

Rotor conductivity

Eddy current brakes rely on the high electrical conductivity of the rotor material to generate opposing magnetic fields and produce braking force without physical contact, whereas friction brakes depend on surface friction and are less affected by rotor conductivity.

Maintenance cycle

Eddy current brakes require significantly less frequent maintenance than friction brakes due to their non-contact operation, resulting in longer service intervals and reduced wear.

Residual magnetization

Residual magnetization in eddy current brakes causes a lingering magnetic field that can affect performance, whereas friction brakes do not exhibit this phenomenon.

eddy current brakes vs friction brakes Infographic

njnir.com

njnir.com