Topology optimization enhances mechanical engineering design by generating material layouts that maximize performance while minimizing weight. Design for manufacturability (DFM) ensures these optimized structures can be efficiently produced, focusing on factors like machining, assembly, and cost reduction. Integrating topology optimization with DFM principles leads to innovative, practical components that balance advanced functionality and scalable manufacturing processes.

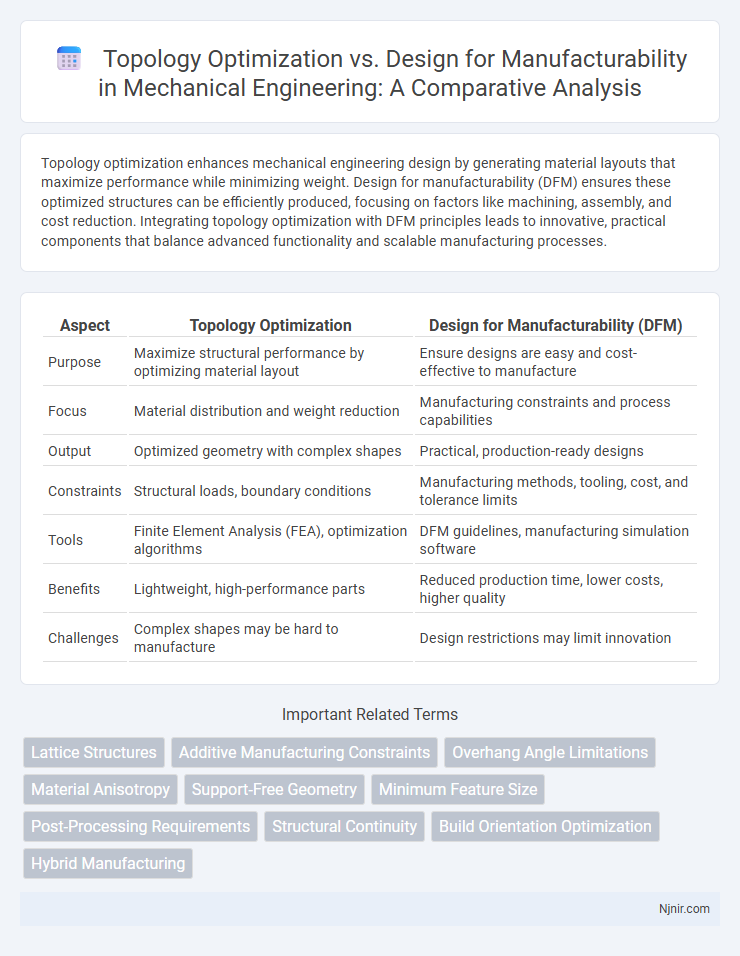

Table of Comparison

| Aspect | Topology Optimization | Design for Manufacturability (DFM) |

|---|---|---|

| Purpose | Maximize structural performance by optimizing material layout | Ensure designs are easy and cost-effective to manufacture |

| Focus | Material distribution and weight reduction | Manufacturing constraints and process capabilities |

| Output | Optimized geometry with complex shapes | Practical, production-ready designs |

| Constraints | Structural loads, boundary conditions | Manufacturing methods, tooling, cost, and tolerance limits |

| Tools | Finite Element Analysis (FEA), optimization algorithms | DFM guidelines, manufacturing simulation software |

| Benefits | Lightweight, high-performance parts | Reduced production time, lower costs, higher quality |

| Challenges | Complex shapes may be hard to manufacture | Design restrictions may limit innovation |

Introduction to Topology Optimization and Design for Manufacturability

Topology optimization uses mathematical algorithms to determine the optimal material distribution within a given design space, maximizing performance while minimizing weight and material usage. Design for manufacturability (DFM) focuses on enhancing product design to simplify manufacturing processes, reduce costs, and improve quality. Integrating topology optimization with DFM ensures that optimized designs are not only structurally efficient but also feasible and cost-effective to produce.

Core Principles of Topology Optimization

Topology optimization focuses on distributing material within a given design space to achieve the best structural performance under specified constraints, utilizing finite element analysis and mathematical modeling to minimize weight while maximizing stiffness and strength. Design for manufacturability (DFM) emphasizes creating designs that simplify production processes, reduce costs, and ensure fabrication feasibility by considering manufacturing limitations and assembly methods. Core principles of topology optimization include material interpolation techniques, constraint handling, and iterative solution updates to evolve the design towards optimal geometry.

Fundamental Concepts of Design for Manufacturability

Design for Manufacturability (DFM) emphasizes optimizing product designs to simplify fabrication processes, reduce costs, and enhance quality by considering manufacturing constraints early in development. It integrates principles such as minimizing part complexity, ensuring standardization of components, and facilitating assembly, which are fundamental to achieving efficient production. Topology optimization, by contrast, focuses on material distribution for structural performance, but must be aligned with DFM concepts to ensure manufacturable outcomes.

Comparative Analysis: Goals and Objectives

Topology optimization aims to maximize structural efficiency by removing unnecessary material to achieve lightweight and high-performance designs, while Design for Manufacturability (DFM) focuses on simplifying production processes, reducing costs, and ensuring reliability during manufacturing. Topology optimization prioritizes mechanical performance and material utilization, whereas DFM emphasizes manufacturability constraints such as tooling limitations, assembly ease, and process capabilities. Effective product development requires balancing these goals to create innovative yet manufacturable components.

Material Selection Impacts in Both Approaches

Topology optimization maximizes structural performance by distributing material efficiently within a design space, heavily influenced by the selected material's mechanical properties such as stiffness and strength. In contrast, Design for Manufacturability (DFM) prioritizes material choices that enhance production feasibility, cost-effectiveness, and compatibility with manufacturing processes like casting, machining, or additive manufacturing. Material selection in topology optimization impacts load-bearing capacity and weight reduction, while in DFM, it governs manufacturability constraints and ensures the design adheres to practical fabrication limits.

Design Constraints and Manufacturing Limitations

Topology optimization focuses on ideal material distribution to maximize structural performance while often overlooking practical constraints, leading to designs that may be difficult to manufacture. Design for manufacturability (DFM) integrates manufacturing limitations such as minimum feature size, tool accessibility, and material anisotropy into the design process to ensure producibility and cost-efficiency. Balancing topology optimization with DFM constraints requires embedding geometric and process-specific restrictions early to avoid infeasible or overly complex structures.

Case Studies: Real-world Applications and Outcomes

Topology optimization enables engineers to create lightweight, high-performance structures by iteratively refining material distribution, as demonstrated in aerospace components where weight reduction improved fuel efficiency by up to 15%. Design for manufacturability (DFM) emphasizes simplifying production processes and minimizing cost, exemplified by automotive part redesigns that reduced machining time by 20% while maintaining structural integrity. Case studies reveal that combining topology optimization with DFM principles results in innovative, feasible products that enhance performance without compromising manufacturability or escalating production expenses.

Integration into Computer-Aided Design (CAD) Workflows

Topology optimization enhances CAD workflows by generating material-efficient designs that push performance boundaries within given constraints. Design for manufacturability (DFM) integrates practical production considerations into CAD models, ensuring that optimized designs are feasible for fabrication using available manufacturing processes. Combining topology optimization with DFM in CAD environments results in innovative, high-performance parts that are both manufacturable and cost-effective.

Future Trends: Additive Manufacturing and Beyond

Topology optimization enhances design efficiency by generating material layouts tailored to specific performance goals, while design for manufacturability (DFM) ensures these designs can be produced cost-effectively and at scale. Future trends emphasize the integration of topology optimization with additive manufacturing technologies, enabling complex geometries that traditional processes cannot achieve and reducing material waste. Advances beyond additive manufacturing include hybrid manufacturing techniques and AI-driven design tools that further streamline production and optimize functional performance.

Best Practices for Balancing Innovation and Manufacturability

Topology optimization enhances structural efficiency by algorithmically distributing material, promoting innovation through novel designs with reduced weight and improved performance. Design for manufacturability (DfM) ensures these optimized designs meet production constraints such as tooling limitations, material selection, and assembly processes, preventing costly revisions or manufacturing failures. Best practices involve iterative collaboration between design and manufacturing teams, leveraging simulation tools to align optimization outcomes with feasible fabrication methods, thereby achieving a balanced approach that maximizes innovation while maintaining manufacturability.

Lattice Structures

Topology optimization enhances lattice structure performance by optimizing material distribution for strength and weight, while design for manufacturability ensures these lattices can be efficiently produced using available fabrication techniques.

Additive Manufacturing Constraints

Topology optimization enhances structural performance by optimizing material layout, while design for manufacturability ensures additive manufacturing constraints like layer thickness, overhang angles, and support structures are met for feasible and efficient production.

Overhang Angle Limitations

Topology optimization often challenges design for manufacturability due to strict overhang angle limitations that restrict self-supporting structures in additive manufacturing.

Material Anisotropy

Topology optimization enhances structural performance by strategically distributing materials, while design for manufacturability prioritizes adapting designs to material anisotropy constraints to ensure feasible production.

Support-Free Geometry

Topology optimization generates material-efficient, complex structures while design for manufacturability prioritizes support-free geometry to minimize post-processing and reduce additive manufacturing costs.

Minimum Feature Size

Topology optimization often produces designs with complex geometries that challenge minimum feature size constraints critical in Design for Manufacturability, requiring specialized filtering techniques to ensure producible and high-quality parts.

Post-Processing Requirements

Topology optimization generates complex geometries requiring extensive post-processing to ensure manufacturability, whereas design for manufacturability emphasizes streamlined post-processing to minimize production challenges.

Structural Continuity

Topology optimization enhances material distribution for maximum structural efficiency, while design for manufacturability prioritizes structural continuity to ensure feasible production and reduce fabrication complexities.

Build Orientation Optimization

Build orientation optimization significantly enhances topology optimization outcomes by improving manufacturability, minimizing support structures, reducing build time, and optimizing mechanical performance in additive manufacturing.

Hybrid Manufacturing

Topology optimization enhances structural efficiency by distributing material within design constraints, while design for manufacturability ensures the hybrid manufacturing process feasibility by addressing material compatibility, process integration, and post-processing requirements.

Topology optimization vs Design for manufacturability Infographic

njnir.com

njnir.com