Laser sintering uses a high-powered laser to selectively fuse powdered material layer by layer, offering precision and a smooth finish ideal for complex geometries. Electron beam melting employs an electron beam in a vacuum environment to melt metal powder, resulting in stronger, denser parts with improved mechanical properties. Both techniques provide additive manufacturing solutions, but laser sintering excels in versatility and surface detail, while electron beam melting is preferred for high-strength aerospace and medical components.

Table of Comparison

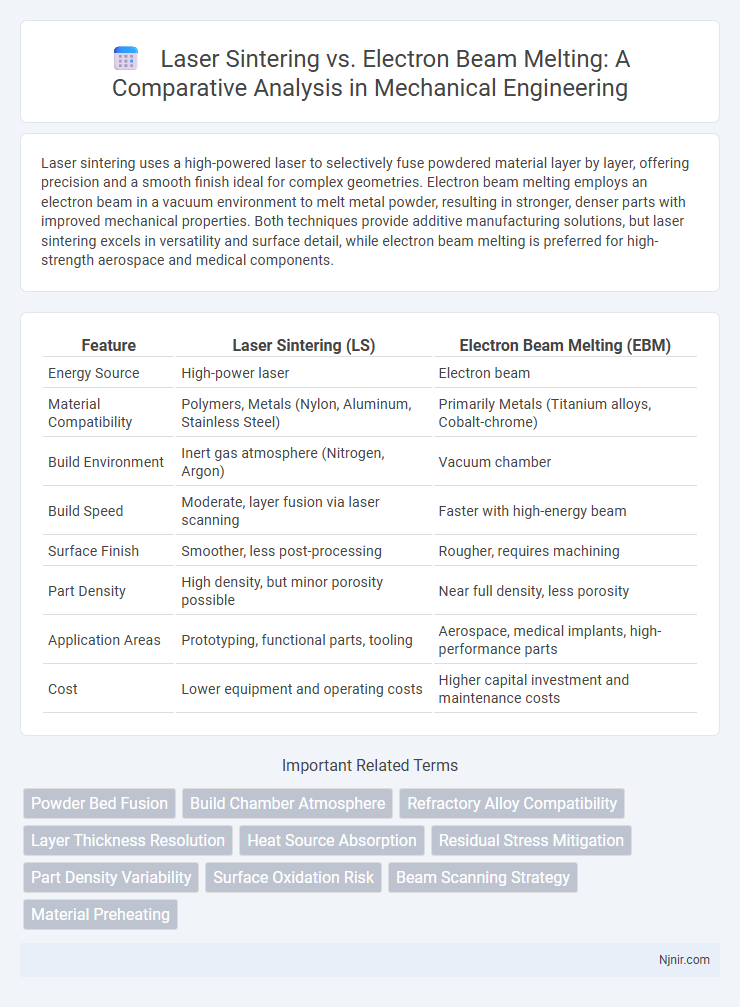

| Feature | Laser Sintering (LS) | Electron Beam Melting (EBM) |

|---|---|---|

| Energy Source | High-power laser | Electron beam |

| Material Compatibility | Polymers, Metals (Nylon, Aluminum, Stainless Steel) | Primarily Metals (Titanium alloys, Cobalt-chrome) |

| Build Environment | Inert gas atmosphere (Nitrogen, Argon) | Vacuum chamber |

| Build Speed | Moderate, layer fusion via laser scanning | Faster with high-energy beam |

| Surface Finish | Smoother, less post-processing | Rougher, requires machining |

| Part Density | High density, but minor porosity possible | Near full density, less porosity |

| Application Areas | Prototyping, functional parts, tooling | Aerospace, medical implants, high-performance parts |

| Cost | Lower equipment and operating costs | Higher capital investment and maintenance costs |

Introduction to Additive Manufacturing Techniques

Laser sintering and electron beam melting are advanced additive manufacturing techniques that build parts layer-by-layer using powdered metals. Laser sintering uses a high-powered laser to selectively fuse metal particles, offering fine resolution and compatibility with various alloys. Electron beam melting employs an electron beam in a vacuum to fully melt metal powder, enabling high-performance, dense components ideal for aerospace and medical applications.

Fundamental Principles of Laser Sintering

Laser sintering operates by using a high-powered laser to selectively fuse powdered material layer by layer, forming solid parts through localized melting and rapid solidification. The process relies on precise control of laser energy, scan speed, and powder properties to achieve optimal part density and mechanical strength. Unlike electron beam melting, which utilizes an electron beam in a vacuum environment, laser sintering typically occurs in an inert gas atmosphere, influencing material compatibility and surface finish.

Basics of Electron Beam Melting Technology

Electron Beam Melting (EBM) utilizes a high-energy electron beam to selectively melt metal powder in a vacuum environment, enabling rapid layer-by-layer fabrication with excellent material properties. Unlike laser sintering, which uses a laser to fuse powder at near-atmospheric pressure, EBM's vacuum setting minimizes oxidation and improves part integrity for high-performance alloys such as titanium and cobalt-chrome. The process achieves full melting of powder particles, resulting in dense, strong components ideal for aerospace, medical implants, and complex geometries.

Material Compatibility and Range Comparison

Laser sintering accommodates a broader range of polymers and metals such as nylon, titanium, and stainless steel, providing versatility for diverse applications. Electron beam melting mainly excels with high-performance metals like titanium alloys and cobalt-chrome, offering superior density and mechanical properties. The broader material compatibility of laser sintering supports applications in automotive and consumer products, whereas electron beam melting is preferred in aerospace and medical implant manufacturing due to its precision with specialized alloys.

Energy Source Differences and Their Effects

Laser sintering uses a high-powered laser to selectively fuse powdered materials, producing precise and detailed metal parts with fine surface finishes. Electron beam melting employs a focused electron beam under a vacuum, resulting in faster build rates and stronger metallurgical properties due to higher energy density and deeper melting. Differences in energy source impact material compatibility, residual stress levels, and microstructural characteristics, influencing the choice between the two for aerospace, medical implants, and high-performance applications.

Process Parameters and Build Environment

Laser sintering utilizes a high-powered laser to selectively fuse powdered material layer by layer in an inert gas atmosphere, typically nitrogen or argon, to prevent oxidation. Electron beam melting employs an electron beam in a vacuum environment that provides superior control over thermal gradients and reduces contamination risks for reactive metals. Process parameters such as beam energy, scan speed, and layer thickness are critical in both methods, influencing part density, surface finish, and mechanical properties.

Mechanical Properties of Finished Parts

Laser sintering produces parts with fine microstructures and good surface finish, resulting in high tensile strength and moderate ductility ideal for complex geometries. Electron beam melting yields components with superior density and enhanced mechanical properties such as increased fatigue resistance and higher yield strength, suitable for aerospace and medical implants. Both processes offer customizable mechanical performance, but electron beam melting typically delivers parts with improved isotropy and reduced residual stress.

Surface Finish and Dimensional Accuracy

Laser sintering delivers finer surface finishes with roughness levels typically around 5-10 microns, supporting intricate detail and smoother part textures ideal for prototypes and functional components. Electron beam melting, operating at higher temperatures, often produces parts with rougher surfaces ranging from 10-20 microns, requiring post-processing to achieve comparable smoothness but offers superior dimensional accuracy due to reduced residual stresses. Dimensional tolerances for laser sintering generally fall between +-0.1 to +-0.3 mm, whereas electron beam melting achieves tighter precision around +-0.05 to +-0.2 mm, making it preferable for aerospace and medical applications demanding exact specifications.

Cost Implications and Production Efficiency

Laser sintering offers lower upfront equipment costs compared to electron beam melting, making it more accessible for small to medium-scale production runs. Electron beam melting, while more expensive due to the need for vacuum chambers and electron beam technology, delivers higher build rates and superior material properties for complex metal parts. Production efficiency in laser sintering benefits from faster setup times and less stringent environment control, whereas electron beam melting requires extended cooling periods and controlled vacuum environments, impacting overall cycle times.

Application Suitability in Mechanical Engineering

Laser sintering excels in producing complex geometries with fine details and is widely used for prototyping and low-volume production of mechanical components requiring high precision and smooth surface finishes. Electron beam melting offers superior mechanical properties and material density, making it ideal for critical load-bearing parts and aerospace-grade applications in mechanical engineering. Both technologies serve distinct roles, with laser sintering favored for design flexibility and electron beam melting preferred for durability in demanding mechanical environments.

Powder Bed Fusion

Laser sintering offers higher precision and finer surface finish in powder bed fusion compared to electron beam melting, which provides faster build rates and better control of residual stresses for large metal parts.

Build Chamber Atmosphere

Laser sintering operates in a controlled nitrogen or argon atmosphere to prevent oxidation, while electron beam melting requires a high vacuum environment to ensure process stability and material purity.

Refractory Alloy Compatibility

Laser sintering offers superior compatibility with refractory alloys like tungsten and molybdenum due to its precise energy control, whereas electron beam melting requires a vacuum environment that limits its effectiveness with certain refractory metals.

Layer Thickness Resolution

Laser sintering achieves finer layer thickness resolution, typically around 20-100 microns, compared to electron beam melting which generally ranges from 40-150 microns, enabling more precise and detailed additive manufacturing.

Heat Source Absorption

Laser sintering achieves higher precision due to better heat source absorption in polymers and metals, while electron beam melting provides deeper penetration and faster melting in conductive materials due to electron beam's superior energy absorption efficiency.

Residual Stress Mitigation

Laser sintering reduces residual stress through controlled heat input and rapid cooling, while electron beam melting minimizes residual stress by operating in a vacuum with intrinsic preheating, resulting in more uniform thermal gradients.

Part Density Variability

Laser sintering typically achieves higher part density consistency compared to electron beam melting, which often results in greater density variability due to its vacuum environment and thermal gradients.

Surface Oxidation Risk

Laser sintering presents a higher surface oxidation risk compared to electron beam melting due to its operation in an oxygen-rich environment, whereas electron beam melting occurs in a vacuum, minimizing oxidation.

Beam Scanning Strategy

Laser sintering employs a raster or vector beam scanning strategy for precise powder melting, while electron beam melting uses a high-energy electron beam with a layer-wise scanning approach to achieve rapid and deep penetration in metal powder fusion.

Material Preheating

Laser sintering preheats material at lower temperatures around 200-300degC to reduce thermal gradients, while electron beam melting uses higher preheating temperatures above 600degC to minimize residual stresses and improve part density.

Laser sintering vs electron beam melting Infographic

njnir.com

njnir.com