Creep refers to the time-dependent deformation of a material under constant stress, causing gradual elongation or distortion. Relaxation, on the other hand, describes the decrease in stress experienced by a material when it is subjected to a constant strain over time. Understanding the differences between creep and relaxation is crucial for designing mechanical components that maintain structural integrity under prolonged loading conditions.

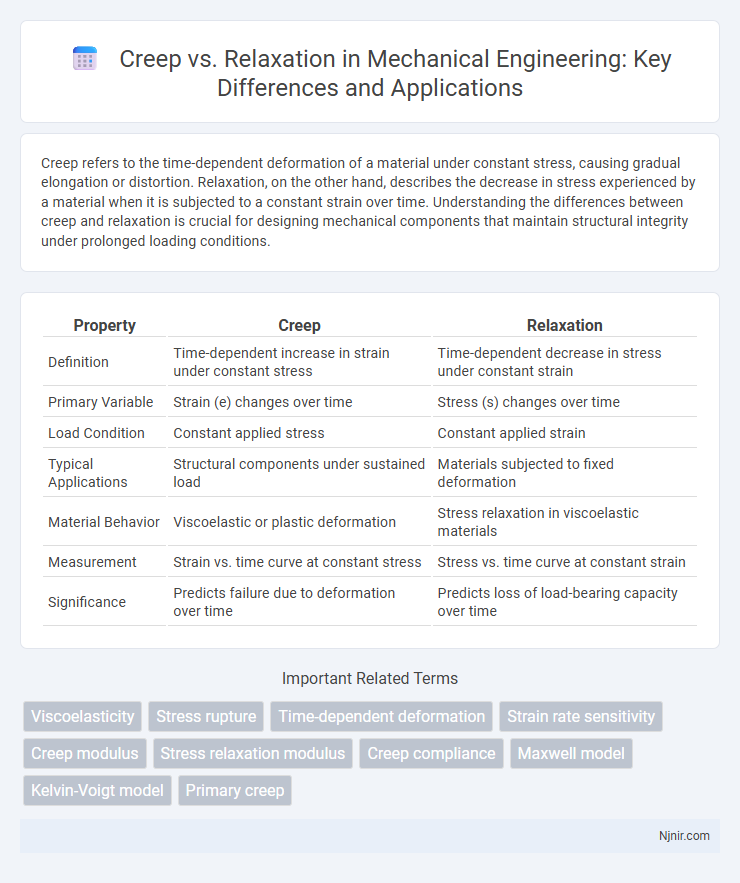

Table of Comparison

| Property | Creep | Relaxation |

|---|---|---|

| Definition | Time-dependent increase in strain under constant stress | Time-dependent decrease in stress under constant strain |

| Primary Variable | Strain (e) changes over time | Stress (s) changes over time |

| Load Condition | Constant applied stress | Constant applied strain |

| Typical Applications | Structural components under sustained load | Materials subjected to fixed deformation |

| Material Behavior | Viscoelastic or plastic deformation | Stress relaxation in viscoelastic materials |

| Measurement | Strain vs. time curve at constant stress | Stress vs. time curve at constant strain |

| Significance | Predicts failure due to deformation over time | Predicts loss of load-bearing capacity over time |

Introduction to Creep and Stress Relaxation

Creep is the time-dependent deformation of materials under constant stress, commonly observed in metals, polymers, and ceramics at elevated temperatures. Stress relaxation refers to the gradual decrease in stress experienced by a material subjected to a constant strain over time. Both phenomena are critical in the design and analysis of components exposed to long-term loading conditions, influencing material selection and safety factors in engineering applications.

Fundamental Concepts: Definitions and Differences

Creep is the time-dependent deformation of a material under constant stress, occurring progressively at a constant load, while relaxation refers to the gradual decrease in stress under constant strain. Both phenomena are fundamental to viscoelastic materials, but creep emphasizes strain increase over time, whereas relaxation focuses on stress reduction. Understanding these differences is critical in material science for predicting long-term behavior of polymers, metals, and composites under operational conditions.

Mechanisms of Creep in Engineering Materials

Creep in engineering materials occurs due to time-dependent plastic deformation under sustained stress, primarily driven by mechanisms such as dislocation movement, diffusion creep, and grain boundary sliding. Dislocation climb and glide enable gradual deformation at elevated temperatures, while diffusion creep involves atom migration through lattice or grain boundaries, facilitating shape change without significant stress increase. Grain boundary sliding accommodates strain by allowing adjacent grains to move relative to each other, often combined with diffusional processes to relieve stress concentrations during creep.

Understanding Stress Relaxation in Mechanical Systems

Stress relaxation in mechanical systems occurs when a material subjected to constant strain gradually decreases in stress over time, reflecting its viscoelastic properties. This phenomenon is critical for designing components that maintain stability under prolonged loading, such as polymers, metals at high temperatures, and elastomers. Understanding stress relaxation enables engineers to predict lifespan and prevent failure by accounting for time-dependent stress reduction in materials under constant deformation.

Factors Influencing Creep Behavior

Material composition, temperature, and applied stress significantly influence creep behavior, with metals and polymers exhibiting different creep rates under identical conditions. Higher temperatures accelerate atomic diffusion and dislocation movement, intensifying creep deformation. Grain size, microstructure, and environmental factors like humidity also affect the rate and extent of creep in materials.

Variables Affecting Stress Relaxation Rates

Stress relaxation rates in materials are significantly influenced by temperature, with higher temperatures accelerating molecular movement and decreasing relaxation time. The applied stress magnitude directly affects relaxation behavior, where larger stresses can induce faster stress decay due to increased internal rearrangements. Material composition, including polymer chain mobility and cross-link density, also plays a crucial role in determining the rate at which stress relaxes under constant strain conditions.

Experimental Methods for Creep Testing

Creep testing involves applying a constant load or stress to a specimen at a controlled temperature and measuring the deformation over time using extensometers or strain gauges for precise strain detection. Typically, tests are conducted in specialized creep testing machines capable of maintaining constant stress and temperature conditions for extended periods, often ranging from hours to thousands of hours. Data acquisition systems record strain versus time curves to assess primary, secondary, and tertiary creep stages, enabling accurate characterization of material behavior under sustained loads.

Techniques for Measuring Stress Relaxation

Stress relaxation is frequently measured using techniques like the classic stress relaxation test, where a material is subjected to a constant strain and the decay in stress is monitored over time using a universal testing machine. Dynamic mechanical analysis (DMA) also provides precise stress relaxation data by applying oscillatory strain and tracking the time-dependent stress response. Advanced methods such as nanoindentation enable localized measurement of stress relaxation in materials with microscale resolution, offering detailed insights into viscoelastic behavior.

Applications and Impacts in Mechanical Design

Creep and relaxation significantly influence mechanical design by dictating material behavior under long-term stress and strain, critical in aerospace, automotive, and structural engineering applications. Designing components such as turbine blades, bridge supports, and pressure vessels requires accounting for creep to prevent deformation over time and relaxation to maintain joint integrity and preload in bolted connections. Failure to consider these time-dependent properties can result in structural fatigue, reduced lifespan, and catastrophic mechanical failure.

Strategies for Minimizing Creep and Relaxation Effects

Effective strategies for minimizing creep and relaxation effects in materials include selecting high-performance alloys or polymers with enhanced resistance to deformation under sustained load. Implementing controlled operating conditions such as maintaining optimal temperature and stress levels helps reduce time-dependent strain and stress relaxation. Regular monitoring and preventive maintenance ensure early detection, allowing for timely adjustments that prolong structural integrity and component lifespan.

Viscoelasticity

Creep and relaxation describe the time-dependent deformation and stress decay behaviors respectively, intrinsic to viscoelastic materials characterized by both elastic and viscous responses.

Stress rupture

Stress rupture describes the failure of materials under prolonged stress at high temperatures, contrasting creep and relaxation by emphasizing time-to-failure rather than deformation or stress decay.

Time-dependent deformation

Creep refers to the progressive, time-dependent deformation under constant stress, while relaxation describes the gradual decrease in stress under constant strain during time-dependent deformation.

Strain rate sensitivity

Strain rate sensitivity significantly influences creep and relaxation behaviors by dictating how materials deform under varying rates of applied stress or strain over time.

Creep modulus

Creep modulus quantifies a material's resistance to time-dependent deformation under constant stress, directly impacting its long-term mechanical performance during creep and relaxation tests.

Stress relaxation modulus

Stress relaxation modulus quantifies a material's decreasing stress response over time under constant strain, essential for differentiating its viscoelastic creep behavior and relaxation properties.

Creep compliance

Creep compliance measures the time-dependent strain response of a material under constant stress, revealing viscoelastic behavior and distinguishing it from relaxation, which evaluates stress decay under constant strain.

Maxwell model

The Maxwell model describes viscoelastic behavior by representing creep as time-dependent strain under constant stress and relaxation as the exponential decay of stress under constant strain.

Kelvin-Voigt model

The Kelvin-Voigt model characterizes creep as time-dependent strain under constant stress, while relaxation is analyzed through the delayed strain response to instantaneous stress changes.

Primary creep

Primary creep is characterized by a decreasing creep rate due to strain hardening as the material adjusts to stress after initial loading.

creep vs relaxation Infographic

njnir.com

njnir.com