Servomechanisms offer precise control of position, speed, and torque using feedback loops, making them ideal for applications requiring high accuracy and dynamic response. Stepper systems operate in discrete steps without feedback, providing simpler control and cost-efficiency but limited accuracy and torque compared to servos. Choosing between servomechanisms and stepper systems depends on the requirements for precision, complexity, and budget in mechanical engineering designs.

Table of Comparison

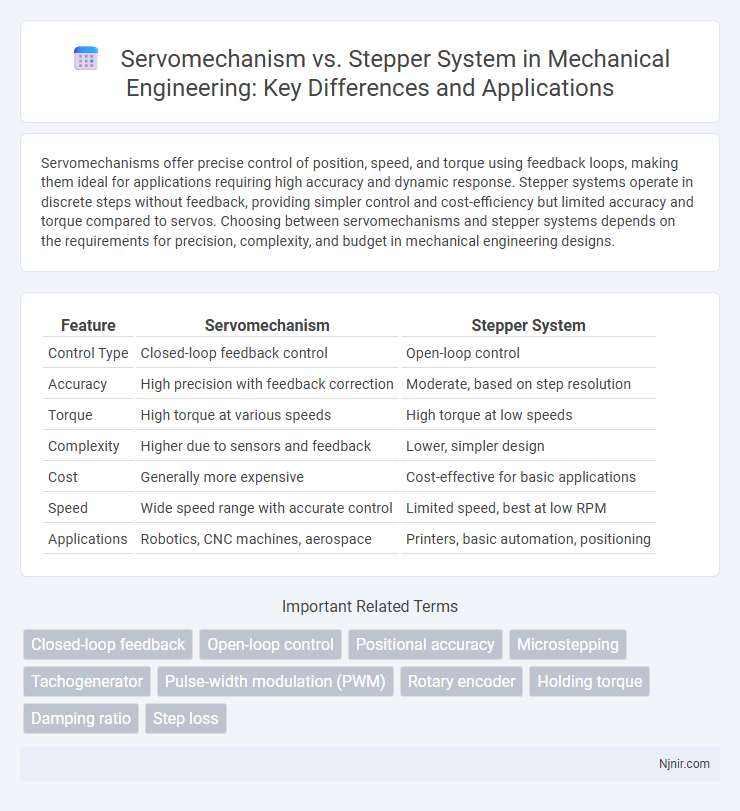

| Feature | Servomechanism | Stepper System |

|---|---|---|

| Control Type | Closed-loop feedback control | Open-loop control |

| Accuracy | High precision with feedback correction | Moderate, based on step resolution |

| Torque | High torque at various speeds | High torque at low speeds |

| Complexity | Higher due to sensors and feedback | Lower, simpler design |

| Cost | Generally more expensive | Cost-effective for basic applications |

| Speed | Wide speed range with accurate control | Limited speed, best at low RPM |

| Applications | Robotics, CNC machines, aerospace | Printers, basic automation, positioning |

Introduction to Servomechanisms and Stepper Systems

Servomechanisms are closed-loop control systems that use feedback to precisely control the position, velocity, or acceleration of mechanical components, often found in robotics and automation for high accuracy. Stepper systems, in contrast, are open-loop devices that move in discrete steps without feedback, providing reliable positioning for applications where simple and cost-effective motion control is sufficient. Understanding the fundamental differences between servomechanisms and stepper systems helps in selecting the appropriate technology based on precision requirements, complexity, and cost constraints.

Basic Operating Principles

Servomechanisms use feedback control to precisely regulate position, velocity, or torque by continuously comparing the output with a desired input signal and adjusting accordingly. Stepper systems operate by dividing a full rotation into discrete steps, moving in fixed increments without requiring feedback, relying on open-loop control for position accuracy. The fundamental difference lies in servomechanisms' closed-loop feedback enabling higher precision and adaptability, while stepper motors offer simplicity and reliability through stepwise motion control.

Key Components Comparison

Servomechanisms primarily consist of a feedback sensor, an error detector, a controller, and an actuator, enabling precise position or speed control by continuously adjusting the output based on feedback. Stepper systems consist of a rotor, stator with multiple windings, and a driver circuit that energizes the coils in a controlled sequence to achieve discrete steps without requiring feedback. The servomechanism's feedback loop offers high accuracy and dynamic response, whereas the stepper system's open-loop design emphasizes simplicity and reliable incremental positioning.

Control Systems and Feedback Mechanisms

Servomechanisms use continuous feedback loops to precisely control speed, position, and torque by adjusting motor inputs based on error signals from sensors, offering high accuracy in dynamic environments. Stepper systems operate through open-loop control by sending discrete step signals to move motors in fixed increments without direct feedback, which limits precision under varying loads. Feedback mechanisms in servomechanisms enable real-time error correction and smoother control, whereas stepper systems rely on predetermined steps and often require external sensors or encoders for closed-loop operation.

Precision and Accuracy

Servomechanisms offer higher precision and accuracy due to their closed-loop feedback control, continuously correcting position errors for smooth and exact motion. Stepper systems operate on an open-loop design, providing incremental movements but can accumulate positioning errors under load without feedback. Consequently, servomechanisms excel in applications demanding fine positional control and repeatability, while steppers suit cost-effective tasks with moderate accuracy requirements.

Speed and Torque Characteristics

Servomechanisms offer high-speed responsiveness with precise torque control, making them ideal for applications requiring dynamic positioning and rapid acceleration. Stepper systems provide consistent torque at low speeds but experience torque diminution at higher speeds, limiting their efficiency in fast-paced operations. The speed-torque curve of servomechanisms typically remains stable across a wide range, while stepper motors exhibit a steep torque drop-off as velocity increases.

Typical Applications in Mechanical Engineering

Servomechanisms are widely used in precision control applications such as robotic arms, CNC machines, and aerospace control systems where accurate position, speed, and torque feedback are critical. Stepper systems find typical applications in 3D printers, small robotics, and automated assembly lines where open-loop control and incremental movements provide reliable and cost-effective solutions. Both systems enhance mechanical engineering designs by improving automation, accuracy, and repeatability in manufacturing and motion control processes.

Advantages and Limitations

Servomechanisms offer precise position control and high torque at variable speeds, making them ideal for dynamic applications with feedback systems enhancing accuracy. Stepper systems provide simplicity, open-loop control, and reliable repeatability without requiring feedback, benefiting cost-sensitive projects with moderate precision needs. However, servomechanisms can be complex and expensive due to sensors and control circuitry, while stepper systems may suffer from resonance issues and limited torque at high speeds.

Cost and Maintenance Considerations

Servomechanisms typically incur higher initial costs due to complex components like encoders and feedback systems but offer precise control and efficiency that can reduce long-term maintenance expenses. Stepper systems are generally more affordable upfront and simpler to maintain because of their open-loop control design, though they may experience wear and require frequent calibration in high-torque applications. Evaluating total cost of ownership involves balancing servomechanism precision and durability against stepper motor affordability and ease of upkeep.

Selection Criteria for Engineering Projects

Selecting between servomechanism and stepper systems depends on precision, speed, and load requirements of engineering projects. Servomechanisms offer high accuracy and dynamic response suitable for applications demanding smooth motion control and variable load handling, while stepper systems excel in cost-effective, open-loop control with moderate precision in low to medium torque settings. Key factors include positional accuracy, torque capacity, environmental conditions, and budget constraints to optimize performance and reliability.

Closed-loop feedback

Servomechanisms utilize closed-loop feedback to continuously monitor and adjust position or speed for high precision, while stepper systems typically operate open-loop without real-time feedback, resulting in less accuracy under variable loads.

Open-loop control

Open-loop stepper systems operate without feedback, providing precise position control through discrete steps, whereas open-loop servomechanisms lack accuracy due to absence of error correction from feedback sensors.

Positional accuracy

Servomechanisms achieve higher positional accuracy than stepper systems due to closed-loop feedback control correcting errors in real-time.

Microstepping

Microstepping enhances stepper motor precision by dividing each full step into smaller microsteps, enabling smoother motion and finer positioning compared to standard servomechanisms.

Tachogenerator

Tachogenerators provide real-time velocity feedback in servomechanisms for precise speed control, whereas stepper systems typically rely on open-loop control without tachogenerator feedback.

Pulse-width modulation (PWM)

Pulse-width modulation (PWM) in servomechanisms enables precise speed and position control through continuous feedback loops, whereas stepper systems use PWM primarily to regulate motor current without inherent positional feedback.

Rotary encoder

Rotary encoders in servomechanisms provide continuous position feedback for precise control, while stepper systems rely on discrete steps without inherent positional feedback, making rotary encoders essential for enhancing servo accuracy and reliability.

Holding torque

Servo systems provide higher holding torque through continuous feedback control, whereas stepper motors offer consistent holding torque without feedback but may lose steps under heavy loads.

Damping ratio

Servomechanisms typically achieve precise control with optimized damping ratios near 0.7 for critical damping, while stepper systems often exhibit lower damping ratios, leading to increased oscillations and less smooth motion.

Step loss

Stepper systems are prone to step loss during high-speed or high-load conditions due to open-loop control, whereas servomechanisms minimize step loss through closed-loop feedback and precise position correction.

servomechanism vs stepper system Infographic

njnir.com

njnir.com