Mechatronics integrates mechanical engineering, electronics, and computer control to design smart systems that improve automation and precision across various industries. Robotics is a subset of mechatronics, emphasizing the creation and operation of programmable machines capable of performing tasks autonomously or semi-autonomously. Understanding the distinct applications and interdisciplinary nature of both fields enhances innovation in automated manufacturing and intelligent system design.

Table of Comparison

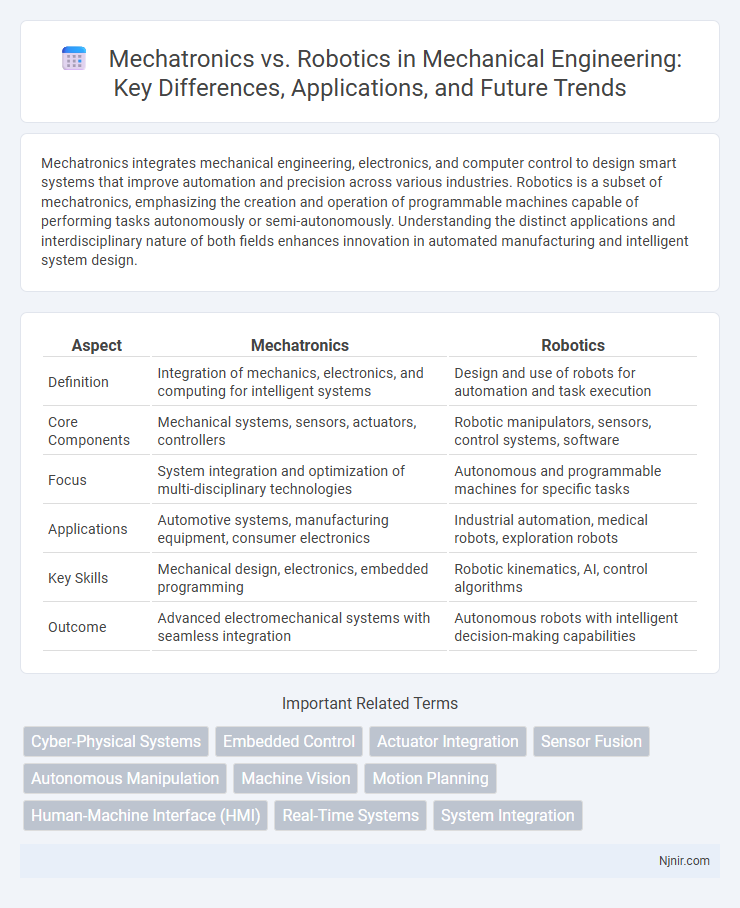

| Aspect | Mechatronics | Robotics |

|---|---|---|

| Definition | Integration of mechanics, electronics, and computing for intelligent systems | Design and use of robots for automation and task execution |

| Core Components | Mechanical systems, sensors, actuators, controllers | Robotic manipulators, sensors, control systems, software |

| Focus | System integration and optimization of multi-disciplinary technologies | Autonomous and programmable machines for specific tasks |

| Applications | Automotive systems, manufacturing equipment, consumer electronics | Industrial automation, medical robots, exploration robots |

| Key Skills | Mechanical design, electronics, embedded programming | Robotic kinematics, AI, control algorithms |

| Outcome | Advanced electromechanical systems with seamless integration | Autonomous robots with intelligent decision-making capabilities |

Introduction to Mechatronics and Robotics

Mechatronics integrates mechanical engineering, electronics, computer control, and systems design to create intelligent products and processes, emphasizing multidisciplinary collaboration. Robotics focuses on the design, construction, operation, and application of robots, combining mechanical systems with sensors and actuators controlled by computer algorithms for automation. The introduction to mechatronics and robotics highlights their synergy in developing smart systems that enhance precision, efficiency, and adaptability in modern engineering solutions.

Defining Mechatronics: Scope and Applications

Mechatronics integrates mechanical engineering, electronics, computer science, and control engineering to design and create intelligent systems and products, emphasizing the synergy between these disciplines. Its scope includes automation, manufacturing robotics, and smart system development, enabling enhanced functionality and efficiency across industries. Applications range from automotive systems and medical devices to consumer electronics and industrial automation, highlighting its broad, multidisciplinary impact compared to the more specialized robotics field.

Understanding Robotics: Key Concepts and Types

Robotics is a specialized field within mechatronics that focuses on the design, construction, operation, and application of robots, integrating mechanical, electrical, and computer engineering principles. Key concepts in robotics include sensors, actuators, control systems, and artificial intelligence, which enable robots to perform tasks autonomously or semi-autonomously. Types of robots range from industrial robots used in manufacturing to service robots in healthcare, each designed for specific environments and functions.

Historical Evolution of Mechatronics and Robotics

Mechatronics emerged in the 1960s as an interdisciplinary approach combining mechanical engineering, electronics, computer control, and systems design to improve manufacturing processes. Robotics evolved concurrently from automation and artificial intelligence research, with early milestones including the introduction of the Unimate robotic arm in 1961, which revolutionized industrial assembly lines. Both fields have continuously converged, advancing through innovations in sensors, actuators, and embedded systems, shaping modern automation and intelligent machine development.

Core Components: Mechatronics vs Robotics

Mechatronics integrates mechanical engineering, electronics, computer control, and systems design to create complex, multifunctional machinery, emphasizing sensors, actuators, microcontrollers, and embedded systems. Robotics focuses on designing and building programmable robots that combine mechanical structures with autonomy through advanced processors, motion controllers, and artificial intelligence. While mechatronics centers on synergy between diverse engineering disciplines, robotics prioritizes intelligent automation and autonomous operation within those integrated systems.

Systems Integration: Hardware and Software Differences

Mechatronics integrates mechanical engineering, electronics, computer science, and control engineering to create multifunctional systems, emphasizing seamless hardware-software interaction for complex automation tasks. Robotics, a subset of mechatronics, concentrates on designing and programming robots, prioritizing sophisticated sensor integration and real-time software for autonomous operation. The key difference lies in mechatronics' broad systems integration approach versus robotics' specialized focus on robotic hardware and intelligent software for movement and task execution.

Industrial Applications: Use Cases in Mechanical Engineering

Mechatronics integrates mechanical engineering, electronics, and computer control to optimize manufacturing systems, enabling precise automation in assembly lines and CNC machinery. Robotics specializes in designing programmable machines for repetitive, hazardous, or high-precision tasks such as welding, painting, and material handling in factories. Both disciplines enhance industrial efficiency, but mechatronics provides a broader systems approach while robotics delivers targeted automation solutions in mechanical engineering environments.

Skills and Interdisciplinary Knowledge Required

Mechatronics requires expertise in mechanical engineering, electronics, computer science, and control systems to design integrated automated systems. Robotics demands specialized knowledge in kinematics, sensors, programming, and artificial intelligence for building autonomous machines. Both fields emphasize strong problem-solving abilities and interdisciplinary collaboration to develop innovative technological solutions.

Future Trends: Emerging Technologies and Innovations

Future trends in mechatronics emphasize the integration of artificial intelligence, advanced sensors, and IoT connectivity to create smarter, more responsive systems. Robotics innovation is increasingly driven by developments in machine learning, collaborative robots (cobots), and bio-inspired designs for enhanced adaptability and efficiency. Both fields are converging towards autonomous, adaptive machines that leverage real-time data processing and edge computing for optimized performance in diverse applications.

Choosing a Career Path: Mechatronics vs Robotics

Choosing a career path in mechatronics or robotics depends on your interest in multidisciplinary engineering versus specialized automation. Mechatronics integrates mechanical, electrical, and software engineering to design complex systems, ideal for those seeking versatility across industries like automotive, manufacturing, and consumer electronics. Robotics focuses specifically on designing, programming, and maintaining robots, offering a deep dive into automation, artificial intelligence, and machine learning applications primarily in sectors such as industrial automation, healthcare, and defense.

Cyber-Physical Systems

Mechatronics integrates mechanical, electronic, and software engineering to design Cyber-Physical Systems, while robotics specifically applies these principles to create autonomous machines within such CPS frameworks.

Embedded Control

Mechatronics integrates embedded control systems with mechanical and electronic components, while robotics emphasizes autonomous operation and advanced control algorithms within embedded systems.

Actuator Integration

Mechatronics integrates diverse actuators such as electric, hydraulic, and pneumatic systems for multifunctional applications, while robotics emphasizes precision actuator integration for autonomous motion and task execution.

Sensor Fusion

Sensor fusion in mechatronics integrates data from diverse sensors to enhance system accuracy and reliability, while in robotics it primarily enables precise environment perception and autonomous decision-making.

Autonomous Manipulation

Autonomous manipulation in mechatronics integrates multidisciplinary systems combining mechanics, electronics, and control to enable adaptive robotic arms, while robotics emphasizes AI-driven decision-making for dynamic interaction and precision in unstructured environments.

Machine Vision

Machine vision in robotics integrates advanced sensors and image processing algorithms to enable autonomous decision-making, whereas mechatronics applies machine vision to enhance system control and precision across multidisciplinary engineering fields.

Motion Planning

Motion planning in mechatronics integrates mechanical, electronic, and control systems for precise movement, while robotics emphasizes autonomous path generation and obstacle avoidance using advanced algorithms.

Human-Machine Interface (HMI)

Mechatronics integrates multidisciplinary engineering to enhance Human-Machine Interfaces (HMI) by combining mechanical, electronic, and software components, while robotics specializes in autonomous machines with advanced HMI for intuitive human control and interaction.

Real-Time Systems

Real-time systems in mechatronics integrate sensors and actuators for precise control, while robotics emphasizes real-time processing for autonomous decision-making and adaptive behavior.

System Integration

Mechatronics emphasizes seamless system integration of mechanical, electronic, and software components to create multifunctional devices, while robotics focuses on integrating these systems specifically for autonomous or semi-autonomous robotic operations.

mechatronics vs robotics Infographic

njnir.com

njnir.com