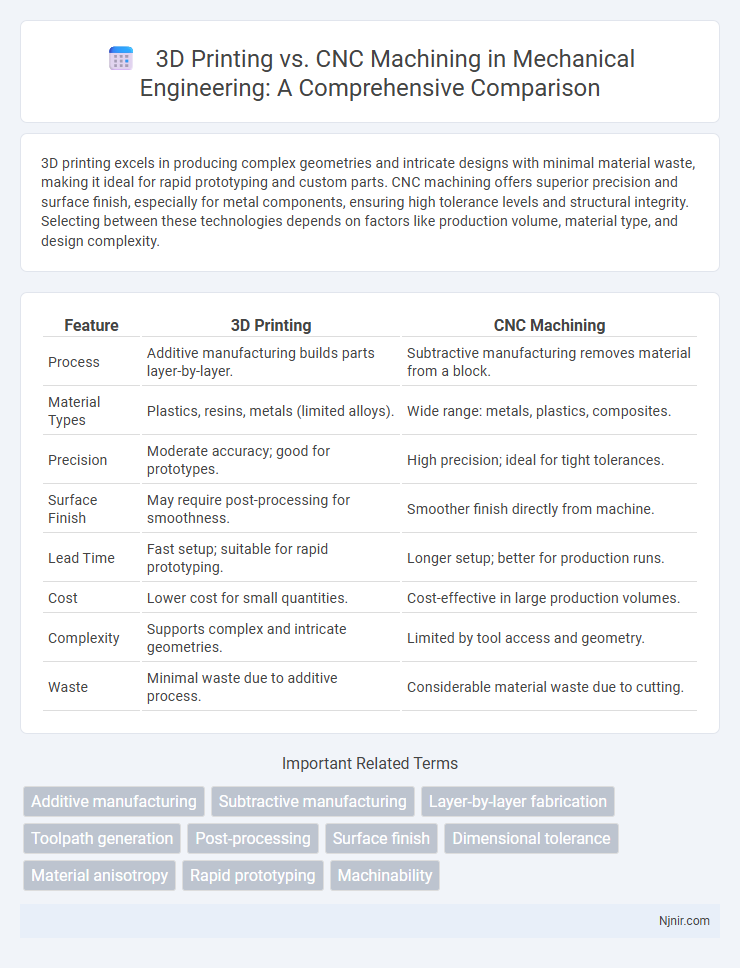

3D printing excels in producing complex geometries and intricate designs with minimal material waste, making it ideal for rapid prototyping and custom parts. CNC machining offers superior precision and surface finish, especially for metal components, ensuring high tolerance levels and structural integrity. Selecting between these technologies depends on factors like production volume, material type, and design complexity.

Table of Comparison

| Feature | 3D Printing | CNC Machining |

|---|---|---|

| Process | Additive manufacturing builds parts layer-by-layer. | Subtractive manufacturing removes material from a block. |

| Material Types | Plastics, resins, metals (limited alloys). | Wide range: metals, plastics, composites. |

| Precision | Moderate accuracy; good for prototypes. | High precision; ideal for tight tolerances. |

| Surface Finish | May require post-processing for smoothness. | Smoother finish directly from machine. |

| Lead Time | Fast setup; suitable for rapid prototyping. | Longer setup; better for production runs. |

| Cost | Lower cost for small quantities. | Cost-effective in large production volumes. |

| Complexity | Supports complex and intricate geometries. | Limited by tool access and geometry. |

| Waste | Minimal waste due to additive process. | Considerable material waste due to cutting. |

Introduction to 3D Printing and CNC Machining

3D printing, also known as additive manufacturing, builds objects layer by layer from digital models using materials like plastic, metal, or resin, offering rapid prototyping and complex geometries. CNC machining, a subtractive process, uses computer-controlled tools to remove material from solid blocks, excelling in precision and surface finish for metal and plastic parts. Both technologies cater to different manufacturing needs, with 3D printing ideal for customized, low-volume production and CNC machining suited for high-accuracy, repeatable parts.

Core Principles and Technologies

3D printing builds objects layer by layer using additive manufacturing techniques such as Fused Deposition Modeling (FDM) and Stereolithography (SLA), allowing complex geometries and rapid prototyping. CNC machining relies on subtractive processes where material is removed from a solid block via computer-controlled cutting tools like mills and lathes, providing high precision and surface finish quality. Both technologies utilize computer-aided design (CAD) files, but 3D printing offers greater design flexibility while CNC excels in material strength and tight tolerances.

Material Compatibility and Choices

3D printing offers a wide range of material compatibility including plastics, resins, metals, and composites, enabling complex geometries and lightweight designs that are difficult to achieve with traditional methods. CNC machining supports a broad spectrum of materials such as aluminum, steel, brass, titanium, and engineered plastics, providing precise tolerances and superior surface finishes ideal for high-strength and functional parts. Material selection depends on factors like mechanical properties, heat resistance, and production volume, with CNC machining favored for metal parts requiring durability and 3D printing preferred for rapid prototyping and intricate designs.

Design Flexibility and Complexity

3D printing offers unmatched design flexibility, enabling the creation of intricate geometries and internal structures that are difficult or impossible to achieve with CNC machining. Complex parts with undercuts, hollow sections, and organic shapes can be fabricated layer by layer, minimizing design constraints. CNC machining excels in producing precise, high-tolerance components but is limited by tool access and geometric complexity, making it less suitable for highly detailed or interwoven designs.

Speed and Production Throughput

3D printing offers rapid prototyping with the ability to produce complex geometries in a single build cycle, making it ideal for low to medium volume production runs. CNC machining provides faster production throughput for high-volume manufacturing due to its ability to quickly produce parts with consistent precision using subtractive processes. While 3D printing excels in customization and complexity, CNC machining remains superior in speed and efficiency for large-scale production.

Surface Finish and Tolerances

3D printing typically produces parts with a rougher surface finish and looser tolerances, often requiring post-processing to achieve smoothness and precision. CNC machining delivers superior surface finishes and tighter tolerances due to its subtractive process, capable of producing parts with micron-level accuracy. Industries demanding high precision and fine detail, such as aerospace and medical device manufacturing, often prefer CNC machining over 3D printing for critical components.

Cost Analysis and Economic Considerations

3D printing offers lower initial equipment costs and minimal material waste, making it cost-effective for small production runs and rapid prototyping. CNC machining involves higher upfront setup expenses and tooling costs but provides superior material efficiency and faster production times for large-scale manufacturing. Evaluating cost per unit based on production volume and part complexity is crucial for determining the most economically viable manufacturing method.

Sustainability and Waste Management

3D printing significantly reduces material waste by building objects layer by layer, only using the necessary amount of raw material, unlike CNC machining which often generates considerable offcuts and scrap. The energy consumption of 3D printers is generally lower per unit produced, contributing to a smaller carbon footprint in manufacturing. Sustainable practices in both technologies include recycling leftover materials and optimizing production processes to minimize environmental impact.

Industry Applications and Case Studies

3D printing excels in rapid prototyping and complex geometries, making it ideal for aerospace and medical device industries where customization and lightweight parts are critical. CNC machining dominates in automotive and heavy machinery sectors due to its precision and efficiency in producing durable metal components with tight tolerances. Case studies show aerospace companies reducing development cycles by 40% with 3D printing, while automotive manufacturers increase production accuracy by 25% using CNC machining.

Choosing the Right Method for Your Project

Selecting the appropriate manufacturing method depends on project requirements such as complexity, material, and production volume. 3D printing excels in creating intricate designs with minimal waste and rapid prototyping, while CNC machining offers superior precision and strength for durable parts. Evaluating factors like cost, lead time, and tolerance will guide the optimal choice between 3D printing and CNC machining.

Additive manufacturing

Additive manufacturing in 3D printing builds complex parts layer by layer, enabling rapid prototyping and reduced material waste compared to subtractive CNC machining.

Subtractive manufacturing

CNC machining, a subtractive manufacturing process, precisely removes material from a solid block to create detailed, durable parts with tight tolerances, offering advantages over 3D printing in strength and surface finish.

Layer-by-layer fabrication

3D printing builds objects through layer-by-layer fabrication using additive processes, whereas CNC machining removes material layer by layer through subtractive methods for precise shaping.

Toolpath generation

CNC machining requires complex, precise toolpath generation to guide cutting tools for accurate material removal, while 3D printing utilizes layer-by-layer toolpaths optimized for additive material deposition efficiency.

Post-processing

Post-processing for 3D printing involves support removal, sanding, and curing to improve surface finish, whereas CNC machining primarily requires deburring and polishing to achieve precise and smooth metal or plastic parts.

Surface finish

CNC machining produces superior surface finishes with tighter tolerances compared to 3D printing, which often requires post-processing to achieve smooth surfaces.

Dimensional tolerance

CNC machining typically achieves tighter dimensional tolerances of +-0.005 mm compared to 3D printing's +-0.1 mm, making CNC preferable for high-precision manufacturing.

Material anisotropy

Material anisotropy in 3D printing often results from layer-by-layer deposition causing directional strength variations, whereas CNC machining produces isotropic parts by removing material from a homogeneous block.

Rapid prototyping

3D printing enables faster and more cost-effective rapid prototyping compared to CNC machining by producing complex geometries directly from digital models without extensive tooling.

Machinability

CNC machining offers superior machinability with high precision and material versatility compared to 3D printing, which excels in complex geometries but often requires post-processing for enhanced mechanical properties.

3D printing vs CNC machining Infographic

njnir.com

njnir.com