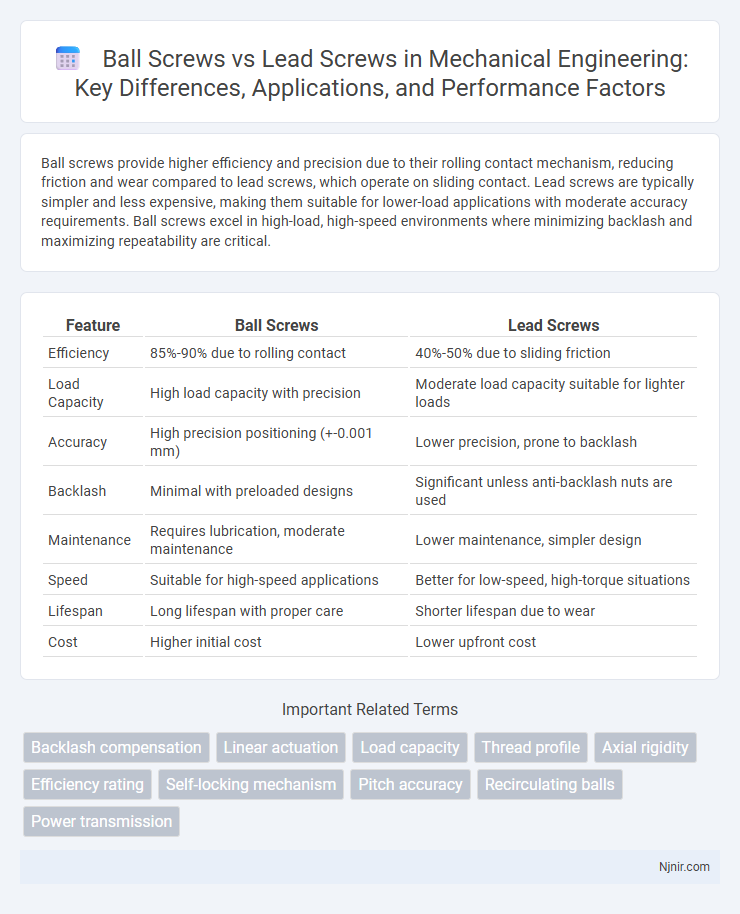

Ball screws provide higher efficiency and precision due to their rolling contact mechanism, reducing friction and wear compared to lead screws, which operate on sliding contact. Lead screws are typically simpler and less expensive, making them suitable for lower-load applications with moderate accuracy requirements. Ball screws excel in high-load, high-speed environments where minimizing backlash and maximizing repeatability are critical.

Table of Comparison

| Feature | Ball Screws | Lead Screws |

|---|---|---|

| Efficiency | 85%-90% due to rolling contact | 40%-50% due to sliding friction |

| Load Capacity | High load capacity with precision | Moderate load capacity suitable for lighter loads |

| Accuracy | High precision positioning (+-0.001 mm) | Lower precision, prone to backlash |

| Backlash | Minimal with preloaded designs | Significant unless anti-backlash nuts are used |

| Maintenance | Requires lubrication, moderate maintenance | Lower maintenance, simpler design |

| Speed | Suitable for high-speed applications | Better for low-speed, high-torque situations |

| Lifespan | Long lifespan with proper care | Shorter lifespan due to wear |

| Cost | Higher initial cost | Lower upfront cost |

Introduction to Ball Screws and Lead Screws

Ball screws and lead screws are mechanical devices used to convert rotational motion into linear motion with high precision. Ball screws utilize ball bearings to reduce friction and increase efficiency, making them ideal for applications requiring high speed and accuracy. Lead screws operate through direct sliding contact between the screw and the nut, offering simplicity and cost-effectiveness but generally exhibiting higher friction and lower efficiency than ball screws.

Fundamental Working Principles

Ball screws operate by converting rotational motion into linear motion through recirculating ball bearings that reduce friction and provide high efficiency. Lead screws rely on a threaded shaft and nut, where the nut moves linearly as the shaft rotates, generating motion through direct sliding contact and higher friction. The fundamental difference lies in the use of rolling elements in ball screws versus sliding contact in lead screws, influencing efficiency, load capacity, and precision.

Design and Construction Differences

Ball screws utilize recirculating ball bearings between the screw shaft and nut, minimizing friction and enabling high efficiency and precision. Lead screws rely on direct sliding contact between the screw thread and nut, resulting in higher friction and wear but simpler construction. The design of ball screws incorporates complex recirculation channels and hardened raceways, while lead screws feature straightforward thread forms typically made from materials with good wear resistance.

Efficiency and Performance Comparison

Ball screws offer higher efficiency, typically achieving 90% or greater, due to rolling motion which reduces friction and wear compared to lead screws' sliding motion with efficiency around 40-70%. This results in smoother, faster, and more precise motion control suitable for high-speed applications. Lead screws, however, provide better holding torque and are simpler in design, making them preferable for low-speed, high-load scenarios despite lower overall efficiency.

Precision and Accuracy Considerations

Ball screws offer superior precision and accuracy due to their low friction and minimal backlash, enabling smoother and more consistent motion control in high-precision applications such as CNC machining and robotics. Lead screws, while simpler and more cost-effective, typically exhibit higher friction and backlash, which can reduce positional accuracy and repeatability in demanding tasks. Choosing between ball screws and lead screws depends on the required tolerance levels and application-specific precision needs.

Load Capacity and Durability Analysis

Ball screws provide higher load capacity due to their rolling elements that reduce friction and distribute load evenly, making them suitable for heavy-duty applications. Lead screws experience greater wear and friction from sliding contact, resulting in lower durability under high load conditions. The enhanced efficiency and longevity of ball screws translate to improved performance in precision machinery and industrial automation.

Friction and Wear Rate Assessment

Ball screws exhibit significantly lower friction and wear rates compared to lead screws due to their rolling contact mechanism between the ball bearings and the screw shaft, which minimizes metal-to-metal sliding. This reduced friction enhances efficiency, extends service life, and lowers maintenance requirements, making ball screws ideal for high-precision and high-load applications. Lead screws, with sliding friction between the nut and the screw, typically experience higher wear rates, resulting in decreased accuracy and increased lubrication needs over time.

Application Suitability and Selection Criteria

Ball screws offer high efficiency, precision, and load capacity, making them ideal for applications requiring fast, accurate motion such as CNC machinery and robotics. Lead screws, with their simpler design and self-locking capability, are suitable for low-speed, low-load applications like positioning systems and handheld devices. Selecting between ball screws and lead screws depends on factors like required speed, load capacity, accuracy, maintenance, and overall system cost.

Maintenance Requirements and Operational Lifespan

Ball screws require regular lubrication and contamination control to maintain optimal performance and extend operational lifespan, typically lasting over 10,000 hours under proper maintenance. Lead screws demand less frequent lubrication but are more prone to wear, often resulting in shorter lifespans around 5,000 hours, especially in high-load or high-speed applications. Choosing between ball screws and lead screws depends on balancing maintenance commitment with desired durability and operational efficiency.

Cost Analysis and Economic Impact

Ball screws typically involve higher initial costs due to precision manufacturing and expensive materials, but their efficiency and durability reduce long-term maintenance expenses. Lead screws are more budget-friendly upfront, offering cost savings for low-load or intermittent applications despite higher friction and wear rates. Evaluating total cost of ownership highlights ball screws' economic advantages in high-volume, high-performance settings, while lead screws remain viable for cost-sensitive projects with less demanding cycles.

Backlash compensation

Ball screws offer superior backlash compensation through precision-ground balls and minimal friction, whereas lead screws typically require external mechanisms or preloaded nuts to achieve similar backlash reduction.

Linear actuation

Ball screws provide higher efficiency and precision in linear actuation compared to lead screws, offering less friction, greater load capacity, and longer service life for industrial automation and CNC machinery.

Load capacity

Ball screws offer significantly higher load capacity and efficiency compared to lead screws due to their rolling element design that reduces friction and wear.

Thread profile

Ball screws feature a circular thread profile that reduces friction and increases efficiency, while lead screws utilize a trapezoidal thread profile that offers higher load capacity but more friction.

Axial rigidity

Ball screws offer higher axial rigidity than lead screws due to their rolling element design, which minimizes friction and backlash while maintaining precise linear motion.

Efficiency rating

Ball screws typically achieve efficiency ratings of 90-95%, significantly outperforming lead screws, which usually range between 20-50% efficiency due to higher friction losses.

Self-locking mechanism

Ball screws lack a self-locking mechanism, requiring external brakes or locks, whereas lead screws inherently provide self-locking due to their higher friction coefficient.

Pitch accuracy

Ball screws offer higher pitch accuracy than lead screws due to their precision-ground grooves and recirculating ball bearings that reduce backlash and ensure consistent linear motion.

Recirculating balls

Recirculating ball screws offer higher efficiency and reduced friction compared to lead screws by continuously circulating ball bearings between the screw shaft and nut, enabling smoother motion and longer service life in precision machinery.

Power transmission

Ball screws offer higher power transmission efficiency up to 90% due to rolling contact, while lead screws typically provide 40-70% efficiency because of sliding friction.

Ball screws vs lead screws Infographic

njnir.com

njnir.com