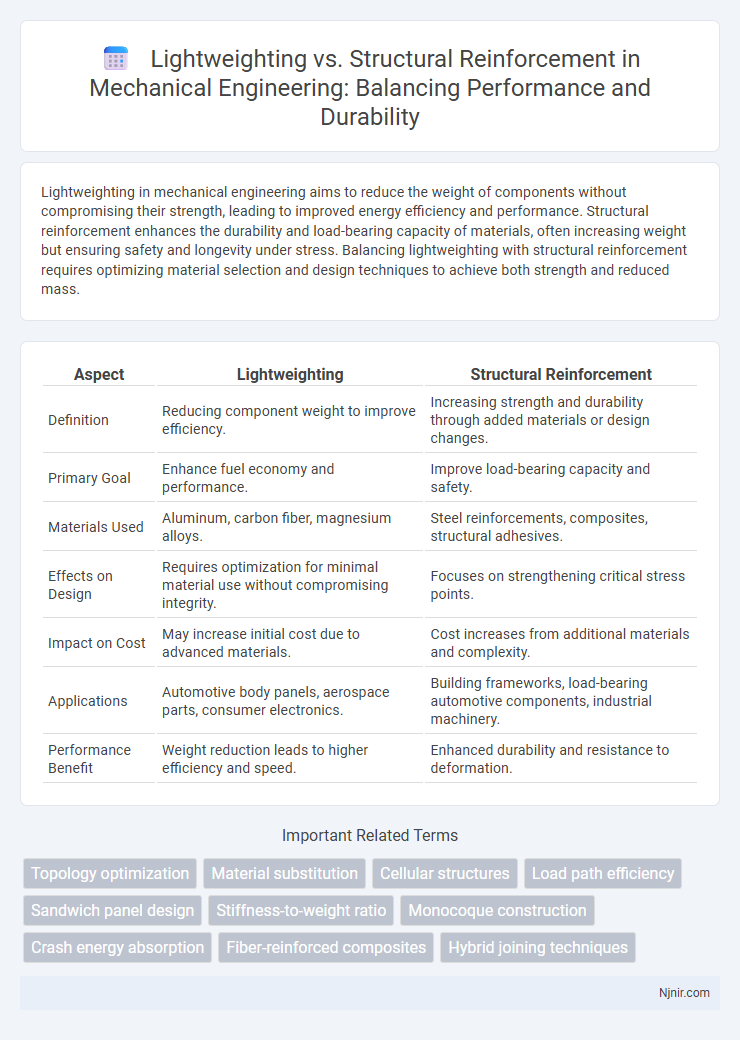

Lightweighting in mechanical engineering aims to reduce the weight of components without compromising their strength, leading to improved energy efficiency and performance. Structural reinforcement enhances the durability and load-bearing capacity of materials, often increasing weight but ensuring safety and longevity under stress. Balancing lightweighting with structural reinforcement requires optimizing material selection and design techniques to achieve both strength and reduced mass.

Table of Comparison

| Aspect | Lightweighting | Structural Reinforcement |

|---|---|---|

| Definition | Reducing component weight to improve efficiency. | Increasing strength and durability through added materials or design changes. |

| Primary Goal | Enhance fuel economy and performance. | Improve load-bearing capacity and safety. |

| Materials Used | Aluminum, carbon fiber, magnesium alloys. | Steel reinforcements, composites, structural adhesives. |

| Effects on Design | Requires optimization for minimal material use without compromising integrity. | Focuses on strengthening critical stress points. |

| Impact on Cost | May increase initial cost due to advanced materials. | Cost increases from additional materials and complexity. |

| Applications | Automotive body panels, aerospace parts, consumer electronics. | Building frameworks, load-bearing automotive components, industrial machinery. |

| Performance Benefit | Weight reduction leads to higher efficiency and speed. | Enhanced durability and resistance to deformation. |

Introduction to Lightweighting and Structural Reinforcement

Lightweighting involves reducing the mass of materials and components to enhance fuel efficiency and performance in automotive and aerospace industries, primarily by using advanced composites and high-strength alloys. Structural reinforcement focuses on increasing a structure's load-bearing capacity and durability through techniques such as adding ribs, gussets, or using thicker materials to improve safety and longevity. Both approaches balance trade-offs between strength, weight, and cost, impacting design strategies in engineering fields.

Engineering Principles Behind Lightweighting

Lightweighting in engineering relies on principles such as material efficiency, stress distribution, and load optimization to reduce weight without compromising structural integrity. Techniques include using advanced composites, high-strength alloys, and topology optimization to maximize strength-to-weight ratios. This approach minimizes inertial forces and improves energy efficiency by focusing on reducing mass while maintaining essential mechanical properties.

Fundamentals of Structural Reinforcement

Structural reinforcement enhances load-bearing capacity and durability by integrating materials like steel, carbon fiber, or composites to existing frameworks, addressing stress concentrations and preventing failure. Lightweighting prioritizes reducing mass through advanced alloys and design optimization without compromising strength, crucial for automotive and aerospace efficiency. Understanding material properties, stress distribution, and bonding techniques forms the core fundamentals of effective structural reinforcement strategies.

Material Selection for Lightweighting vs Reinforcement

Material selection for lightweighting emphasizes high strength-to-weight ratio materials such as aluminum alloys, carbon fiber composites, and advanced polymers to reduce overall weight without compromising performance. Structural reinforcement prioritizes materials with high durability and toughness like high-strength steel, titanium alloys, and fiber-reinforced composites to enhance load-bearing capacity and resist deformation. Balancing these material properties is critical for optimizing both weight reduction and structural integrity in engineering applications.

Design Considerations: Weight Reduction vs Strength Enhancement

Balancing lightweighting and structural reinforcement requires careful evaluation of material properties, load conditions, and safety factors to optimize both weight reduction and strength enhancement. Advanced composites and high-strength alloys enable significant weight savings while maintaining or improving structural integrity under dynamic and static loads. Design considerations must incorporate finite element analysis and real-world stress testing to ensure durability and performance without compromising fuel efficiency or operational safety.

Performance Impacts: Efficiency, Durability, and Safety

Lightweighting significantly enhances vehicle efficiency by reducing mass, which lowers fuel consumption and emissions while maintaining acceptable durability through advanced composite materials. Structural reinforcement improves safety and durability by increasing stiffness and impact resistance but often adds weight, potentially decreasing fuel efficiency. Balancing lightweighting with targeted structural reinforcement optimizes overall performance, ensuring efficient energy use without compromising crashworthiness or longevity.

Cost-Benefit Analysis: Lightweighting vs Structural Reinforcement

Lightweighting offers significant cost savings by reducing material usage and improving fuel efficiency, directly lowering operational expenses over a product's lifecycle. Structural reinforcement increases durability and safety but often involves higher upfront material and manufacturing costs, which may not proportionally translate into long-term financial benefits. A thorough cost-benefit analysis must weigh initial investments against lifecycle savings, emphasizing that lightweighting typically yields greater economic returns in industries where efficiency is critical, such as automotive and aerospace.

Common Applications in Mechanical Engineering

Lightweighting is commonly applied in automotive and aerospace engineering to reduce vehicle mass, improve fuel efficiency, and enhance performance by using materials such as aluminum alloys, carbon fiber composites, and advanced polymers. Structural reinforcement, often seen in civil and mechanical structures, involves adding materials like steel plates, fiber-reinforced polymers, or carbon nanotubes to increase strength, durability, and load-bearing capacity without significantly altering design dimensions. Mechanical engineers balance lightweighting and structural reinforcement techniques in applications like turbine blades, chassis components, and pressure vessels to achieve optimal strength-to-weight ratios and meet safety and performance standards.

Challenges and Limitations of Each Approach

Lightweighting in automotive design often faces challenges such as maintaining structural integrity while reducing material mass, leading to potential compromises in durability and crash safety. Structural reinforcement increases vehicle weight and can negatively impact fuel efficiency and emissions, limiting its sustainability benefits. Both approaches require balanced engineering solutions to optimize performance without sacrificing safety or environmental goals.

Future Trends in Mechanical Design: Integration of Lightweighting and Reinforcement

Future trends in mechanical design emphasize the integration of lightweighting and structural reinforcement through advanced materials like carbon fiber composites and high-strength aluminum alloys, enhancing strength-to-weight ratios. Innovative manufacturing techniques such as additive manufacturing enable precise control over reinforcement placement, optimizing performance while minimizing mass. Smart materials and adaptive structures are increasingly incorporated to provide real-time load response, achieving a balance between durability and weight reduction.

Topology optimization

Topology optimization enhances lightweighting by strategically redistributing material to achieve maximum structural performance with minimal weight.

Material substitution

Material substitution in lightweighting replaces traditional heavy materials with advanced composites or alloys to maintain structural reinforcement while significantly reducing weight.

Cellular structures

Cellular structures enhance lightweighting by providing high strength-to-weight ratios through optimized material distribution and energy absorption capabilities compared to traditional structural reinforcement methods.

Load path efficiency

Load path efficiency improves vehicle performance by optimizing lightweighting strategies while maintaining structural reinforcement to ensure strength and durability.

Sandwich panel design

Sandwich panel design optimizes lightweighting by combining thin, strong facings with a lightweight core to enhance structural reinforcement while minimizing overall weight.

Stiffness-to-weight ratio

Lightweighting improves the stiffness-to-weight ratio by reducing mass without compromising structural rigidity, while structural reinforcement increases stiffness often at the expense of added weight.

Monocoque construction

Monocoque construction enhances lightweighting by integrating the vehicle's frame and body into a single unit, reducing weight while maintaining structural reinforcement through optimized material distribution.

Crash energy absorption

Lightweighting enhances vehicle efficiency but requires advanced materials or design strategies to maintain crash energy absorption comparable to traditional structural reinforcement methods.

Fiber-reinforced composites

Fiber-reinforced composites enable lightweighting by providing high strength-to-weight ratios while enhancing structural reinforcement in aerospace, automotive, and construction applications.

Hybrid joining techniques

Hybrid joining techniques enhance lightweighting by combining adhesive bonding and mechanical fastening to improve structural reinforcement and load distribution in automotive and aerospace applications.

Lightweighting vs structural reinforcement Infographic

njnir.com

njnir.com