Compliant mechanisms achieve motion through the elastic deformation of flexible members, reducing the number of parts and simplifying assembly compared to traditional rigid mechanisms that rely on rigid bodies and movable joints. These mechanisms offer enhanced precision, lower maintenance, and improved reliability due to fewer wear-prone components. However, the design process requires careful consideration of material properties and stress distribution to ensure durability and optimal performance.

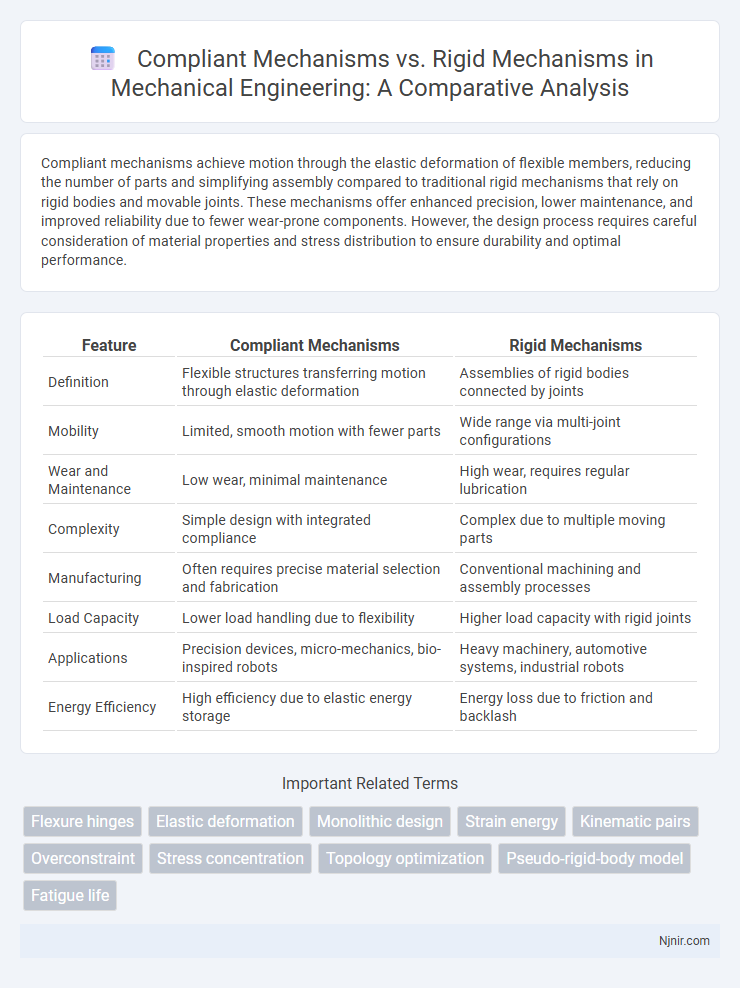

Table of Comparison

| Feature | Compliant Mechanisms | Rigid Mechanisms |

|---|---|---|

| Definition | Flexible structures transferring motion through elastic deformation | Assemblies of rigid bodies connected by joints |

| Mobility | Limited, smooth motion with fewer parts | Wide range via multi-joint configurations |

| Wear and Maintenance | Low wear, minimal maintenance | High wear, requires regular lubrication |

| Complexity | Simple design with integrated compliance | Complex due to multiple moving parts |

| Manufacturing | Often requires precise material selection and fabrication | Conventional machining and assembly processes |

| Load Capacity | Lower load handling due to flexibility | Higher load capacity with rigid joints |

| Applications | Precision devices, micro-mechanics, bio-inspired robots | Heavy machinery, automotive systems, industrial robots |

| Energy Efficiency | High efficiency due to elastic energy storage | Energy loss due to friction and backlash |

Definition of Compliant Mechanisms

Compliant mechanisms are flexible structures that gain at least some of their motion from the deformation of their components, eliminating the need for traditional joints or hinges found in rigid mechanisms. These mechanisms enable motion through elastic energy storage and release, which enhances precision, reduces parts, and lowers manufacturing costs. Their design often incorporates materials with specific elastic properties to achieve desired performance without the complexity of assemblies.

Definition of Rigid Mechanisms

Rigid mechanisms consist of distinct, inflexible components connected through joints that allow relative motion without deformation of the links themselves. Each rigid link maintains its shape under load, transferring forces precisely through pivot or sliding joints to achieve desired mechanical movements. These mechanisms are characterized by their dependability in applications requiring high precision and minimal elastic deformation.

Fundamental Differences

Compliant mechanisms achieve motion through the elastic deformation of flexible materials, enabling smooth, continuous movement without traditional joints or bearings, while rigid mechanisms rely on rigid body parts connected by pin joints or hinges. The primary advantage of compliant mechanisms lies in reduced part count, lower friction, and absence of wear-prone components, enhancing durability and precision. Fundamental differences include the energy storage in elastic deformation for compliant designs versus discrete rotational motion in rigid counterparts.

Material Selection Criteria

Material selection for compliant mechanisms prioritizes flexibility, fatigue resistance, and elastic deformation capabilities, favoring polymers, elastomers, and certain metals like titanium for their high strength-to-weight ratios. In contrast, rigid mechanisms require materials with high stiffness, hardness, and wear resistance such as steel, aluminum, and ceramics to ensure structural integrity and minimal deformation under load. Understanding the operational environment, load conditions, and lifecycle demands is critical for choosing materials that optimize performance and durability in both mechanism types.

Design Principles and Methodologies

Compliant mechanisms achieve motion through elastic deformation of flexible elements, eliminating the need for traditional joints and hinges found in rigid mechanisms, which rely on discrete rigid-body parts connected by pins or bearings. Design principles of compliant mechanisms emphasize flexibility, material selection, and stress distribution to maximize performance and durability, often utilizing topology optimization and beam theory methodologies. Rigid mechanisms focus on kinematic chains and precise joint placement, relying on rigid body motion analysis and classical mechanical design techniques.

Applications of Compliant Mechanisms

Compliant mechanisms excel in applications requiring precise motion control with minimal friction and wear, such as in microelectromechanical systems (MEMS), biomedical devices, and flexible robotics. Their ability to achieve complex motion through elastic deformation enables lightweight, compact designs ideal for aerospace and consumer electronics. These mechanisms offer advantages in durability and manufacturability for devices that benefit from reduced assembly complexity and enhanced reliability.

Applications of Rigid Mechanisms

Rigid mechanisms are extensively used in automotive transmissions, industrial robots, and aerospace structures due to their ability to maintain precise motion and high load-bearing capacity. The stiffness and durability of rigid linkages make them ideal for applications requiring minimal deflection and high positional accuracy. Common examples include gear trains, lever systems, and robotic arms where mechanical reliability and repeatability are critical.

Advantages and Limitations

Compliant mechanisms offer advantages such as reduced part count, increased reliability due to fewer joints, and the ability to achieve complex motion through elastic deformation, which improves precision and reduces assembly costs. However, their limitations include material fatigue over repeated cycles, limited load-bearing capacity, and challenges in designing for large deformations without permanent damage. In contrast, rigid mechanisms provide high load capacity and predictable motion but suffer from increased weight, complexity, and maintenance due to numerous discrete components and joints.

Performance Comparison

Compliant mechanisms leverage material elasticity to achieve motion, offering reduced friction, wear, and assembly complexity compared to rigid mechanisms that rely on hinges and joints. Performance-wise, compliant mechanisms provide enhanced precision and repeatability, especially in microscale applications, due to fewer moving parts and inherent energy storage capabilities. However, rigid mechanisms generally excel in load-bearing capacity and durability under high-stress conditions, making them preferable for heavy-duty tasks.

Future Trends in Mechanism Design

Future trends in mechanism design emphasize the integration of compliant mechanisms due to their inherent flexibility, lightweight structure, and reduced assembly requirements compared to traditional rigid mechanisms. Advances in materials science, such as smart polymers and additive manufacturing, enable complex, multi-functional compliant designs that improve performance and durability. The shift towards bio-inspired and soft robotics further accelerates the adoption of compliant mechanisms in precision applications and adaptive systems.

Flexure hinges

Flexure hinges in compliant mechanisms offer precise motion with reduced friction and wear compared to traditional rigid mechanisms using pin joints.

Elastic deformation

Compliant mechanisms leverage elastic deformation to transfer motion and force without traditional joints, enabling simpler designs with fewer parts than rigid mechanisms.

Monolithic design

Monolithic compliant mechanisms leverage flexible material deformation to achieve motion within a single, continuous structure, contrasting with rigid mechanisms that rely on discrete joints and assemblies.

Strain energy

Compliant mechanisms store and release strain energy through elastic deformation in flexible elements, whereas rigid mechanisms rely on rigid-body motion and typically minimize strain energy to avoid material stress and deformation.

Kinematic pairs

Compliant mechanisms utilize flexible kinematic pairs that achieve motion through material deformation, whereas rigid mechanisms rely on traditional kinematic pairs with rigid-body joints to enable relative motion.

Overconstraint

Compliant mechanisms minimize overconstraint by utilizing flexible components to achieve motion through elastic deformation, unlike rigid mechanisms that often suffer from increased overconstraint due to their reliance on multiple rigid joints and links.

Stress concentration

Compliant mechanisms reduce stress concentration by utilizing flexible components that distribute loads more evenly, unlike rigid mechanisms that rely on discrete joints and often suffer from high stress concentrations at these points.

Topology optimization

Topology optimization enhances compliant mechanisms by enabling flexible, monolithic designs with reduced part counts and improved durability compared to traditional rigid mechanisms.

Pseudo-rigid-body model

The pseudo-rigid-body model simplifies the analysis of compliant mechanisms by approximating flexible segments as equivalent rigid links connected by rotational springs, enabling accurate prediction of their nonlinear deformation behavior compared to traditional rigid mechanisms.

Fatigue life

Compliant mechanisms generally exhibit longer fatigue life than rigid mechanisms by distributing stress through elastic deformation, reducing stress concentrations and material fatigue.

Compliant mechanisms vs Rigid mechanisms Infographic

njnir.com

njnir.com