Flat belts offer higher speed and smoother operation with less slippage compared to V-belts, making them ideal for applications requiring consistent speed and low maintenance. V-belts provide superior grip and torque transmission due to their wedged design, which enhances power transmission efficiency and reduces the risk of belt slippage under heavy loads. Choosing between flat and V-belts depends on factors such as load capacity, alignment precision, and maintenance requirements in mechanical drive systems.

Table of Comparison

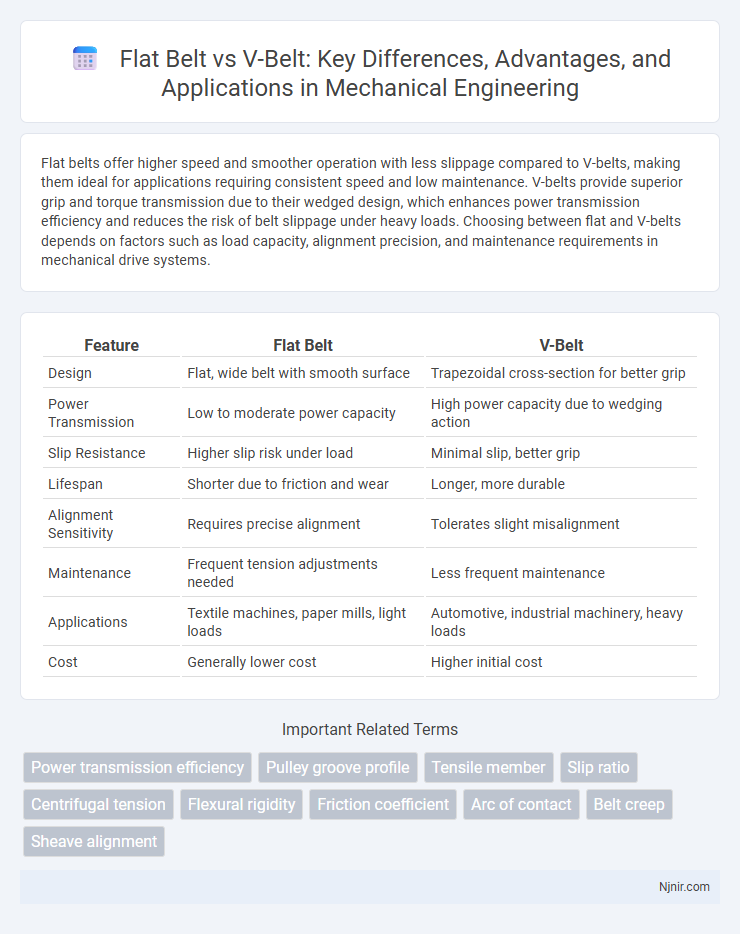

| Feature | Flat Belt | V-Belt |

|---|---|---|

| Design | Flat, wide belt with smooth surface | Trapezoidal cross-section for better grip |

| Power Transmission | Low to moderate power capacity | High power capacity due to wedging action |

| Slip Resistance | Higher slip risk under load | Minimal slip, better grip |

| Lifespan | Shorter due to friction and wear | Longer, more durable |

| Alignment Sensitivity | Requires precise alignment | Tolerates slight misalignment |

| Maintenance | Frequent tension adjustments needed | Less frequent maintenance |

| Applications | Textile machines, paper mills, light loads | Automotive, industrial machinery, heavy loads |

| Cost | Generally lower cost | Higher initial cost |

Introduction to Belt Drives in Mechanical Engineering

Belt drives are essential components in mechanical engineering, used for power transmission between rotating shafts. Flat belts provide high-speed, low-torque transmission with minimal slippage, making them suitable for applications requiring smooth and efficient motion. V-belts offer superior grip and torque capacity due to their trapezoidal cross-section, making them ideal for higher load applications and reducing belt slippage in intermittent or heavy-duty operations.

Overview of Flat Belts

Flat belts are characterized by their wide, thin, and flexible design, commonly made from materials such as rubber, leather, or synthetic fibers, providing smooth and efficient power transmission over long distances. They operate with low friction and minimal slip, making them ideal for high-speed applications in industries like textile manufacturing and conveyor systems. Unlike V-belts, flat belts require larger pulleys and proper tensioning but offer advantages in terms of energy efficiency and quieter operation.

Overview of V-Belts

V-belts are trapezoidal-shaped belts commonly used in mechanical power transmission due to their efficient grip and ability to handle high torque loads. Constructed from rubber or synthetic materials with embedded cords, V-belts provide reliable performance in automotive engines, industrial machinery, and agricultural equipment. Their design allows for self-centering in pulleys, reducing slippage and enhancing overall system efficiency compared to flat belts.

Material and Construction Differences

Flat belts are typically made from materials like leather, rubber, or synthetic polymers, featuring a smooth, flat surface ideal for low-friction power transmission. V-belts consist of rubber or synthetic rubber embedded with high-tensile fibers such as polyester or aramid, designed with a trapezoidal cross-section to fit securely into pulleys for enhanced grip and torque transfer. The flat belt's simple construction contrasts with the multi-layered, reinforced structure of V-belts, which provides greater durability and resistance to stretching and slipping in high-torque applications.

Power Transmission Efficiency

Flat belts offer higher power transmission efficiency due to their larger contact surface area and reduced slip compared to V-belts, resulting in less energy loss during operation. V-belts provide better grip and are more suitable for applications with higher torque demands but tend to have slightly lower efficiency because of increased friction and heat generation. Selecting the appropriate belt depends on balancing efficiency requirements with load conditions and durability needs in power transmission systems.

Installation and Maintenance Requirements

Flat belts require precise alignment and tensioning during installation to prevent slippage and ensure efficient power transmission, while V-belts are easier to install due to their wedge-shaped design that fits securely into pulley grooves. Maintenance for flat belts involves regular inspection for wear, fraying, and realignment, whereas V-belts typically need less frequent adjustment but require monitoring for cracks and proper tension to avoid premature failure. Choosing between the two depends on the specific application's need for ease of maintenance and installation precision.

Applications of Flat Belts vs. V-Belts

Flat belts are commonly used in high-speed, low-torque applications such as conveyor systems, textile machinery, and packaging equipment, where smooth and efficient power transmission is essential. V-belts excel in heavy-duty applications requiring high torque and superior grip, including automotive engines, industrial machinery, and agricultural equipment. The choice between flat belts and V-belts depends on the required power transmission efficiency, load capacity, and environmental conditions of the specific application.

Cost Comparison and Economic Considerations

Flat belts generally offer lower initial costs compared to V-belts due to simpler manufacturing and reduced material requirements. However, V-belts provide better energy efficiency and longer service life, which can lead to lower long-term maintenance and replacement expenses. Evaluating total cost of ownership for both belt types involves considering upfront investment alongside factors such as durability, performance, and downtime.

Advantages and Disadvantages of Each Belt Type

Flat belts offer high-speed operation with low friction and energy loss, making them ideal for long-distance power transmission; however, they can slip under heavy load and require precise alignment. V-belts provide excellent grip and power transmission in compact spaces, minimizing slippage and reducing maintenance needs, but they generate more heat and wear faster under heavy loads. Choosing between flat and V-belts depends on factors like load capacity, speed requirements, and environmental conditions for optimal performance.

Key Factors for Belt Selection in Mechanical Systems

Key factors for selecting flat belts versus V-belts in mechanical systems include load capacity, efficiency, and alignment requirements. Flat belts offer higher speed capabilities and lower friction losses, ideal for applications with light to moderate loads and precise alignment. V-belts provide superior grip and torque transmission, making them suitable for high-load, heavy-duty environments where slip resistance and durability are critical.

Power transmission efficiency

Flat belts offer higher power transmission efficiency than V-belts due to reduced friction and slip, making them ideal for high-speed, low-torque applications.

Pulley groove profile

V-belt pulleys feature a trapezoidal groove profile optimizing friction and torque transmission, whereas flat belt pulleys have a smooth, flat groove designed for high-speed, low-friction power transfer.

Tensile member

The tensile member in a flat belt typically consists of woven fabric or synthetic fibers providing flexibility and moderate strength, while in a V-belt, it is reinforced with high-tensile steel cords or polyester cords for superior strength and durability.

Slip ratio

V-belts exhibit a lower slip ratio than flat belts due to their wedging action in pulleys, resulting in more efficient power transmission and reduced wear.

Centrifugal tension

Centrifugal tension in V-belts increases with speed, enhancing grip and reducing slippage, while flat belts experience lower centrifugal tension, making them less effective at high speeds.

Flexural rigidity

V-belts exhibit higher flexural rigidity than flat belts, enhancing their durability and performance in high-torque power transmission applications.

Friction coefficient

V-belts generally have a higher friction coefficient ranging from 0.3 to 0.4 compared to flat belts, which typically have a friction coefficient between 0.2 and 0.3, enhancing power transmission efficiency in V-belts.

Arc of contact

The arc of contact in flat belts is generally larger than in V-belts, providing better friction and power transmission efficiency on pulleys.

Belt creep

Belt creep occurs more frequently in flat belts than V-belts due to the lower frictional contact area and lack of wedging action in flat belts.

Sheave alignment

Precise sheave alignment minimizes wear and ensures optimal power transmission efficiency in both flat belt and V-belt drive systems.

Flat belt vs V-belt Infographic

njnir.com

njnir.com