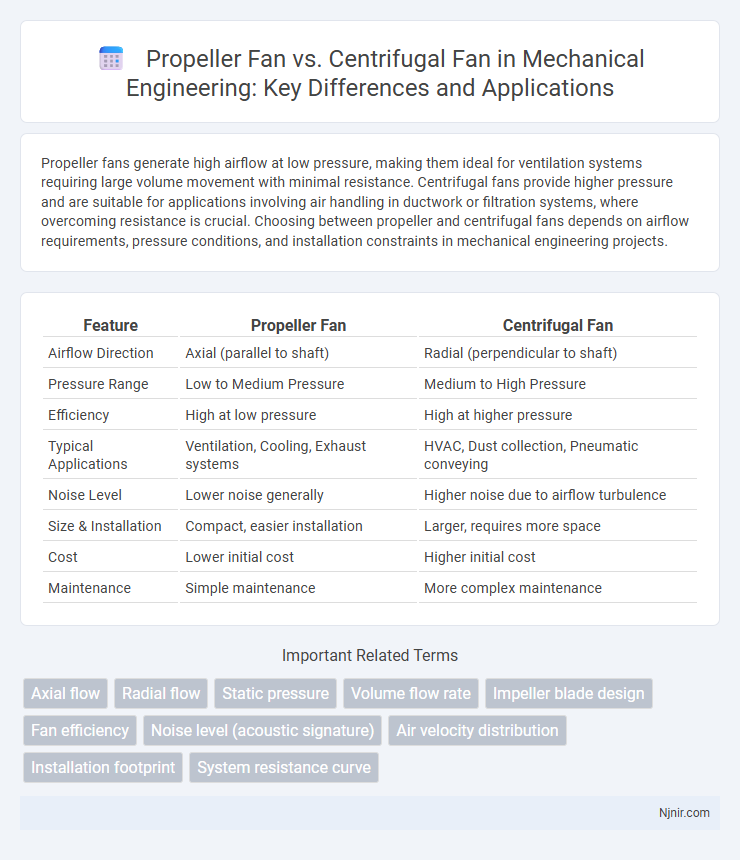

Propeller fans generate high airflow at low pressure, making them ideal for ventilation systems requiring large volume movement with minimal resistance. Centrifugal fans provide higher pressure and are suitable for applications involving air handling in ductwork or filtration systems, where overcoming resistance is crucial. Choosing between propeller and centrifugal fans depends on airflow requirements, pressure conditions, and installation constraints in mechanical engineering projects.

Table of Comparison

| Feature | Propeller Fan | Centrifugal Fan |

|---|---|---|

| Airflow Direction | Axial (parallel to shaft) | Radial (perpendicular to shaft) |

| Pressure Range | Low to Medium Pressure | Medium to High Pressure |

| Efficiency | High at low pressure | High at higher pressure |

| Typical Applications | Ventilation, Cooling, Exhaust systems | HVAC, Dust collection, Pneumatic conveying |

| Noise Level | Lower noise generally | Higher noise due to airflow turbulence |

| Size & Installation | Compact, easier installation | Larger, requires more space |

| Cost | Lower initial cost | Higher initial cost |

| Maintenance | Simple maintenance | More complex maintenance |

Introduction to Propeller and Centrifugal Fans

Propeller fans utilize axial airflow to move air directly through the blades, offering high volume and low pressure suitable for ventilation and cooling applications. Centrifugal fans generate airflow by increasing pressure through radial movement, providing higher pressure and efficiency ideal for air purification and industrial processes. Understanding the differences in airflow direction, pressure capacity, and application suitability is essential for selecting the appropriate fan type.

Operating Principles of Propeller Fans

Propeller fans operate by spinning blades around an axis to generate airflow parallel to the blade orientation, utilizing aerodynamic lift to move air efficiently. The axial flow design allows for high volume, low-pressure air movement, making them ideal for ventilation and cooling applications. Unlike centrifugal fans, propeller fans rely on blade pitch and speed rather than centrifugal force to produce airflow.

Operating Principles of Centrifugal Fans

Centrifugal fans operate by drawing air into the center of a rotating impeller, which uses centrifugal force to propel the air outward through a spiral casing. This design creates high pressure and steady airflow, making centrifugal fans ideal for applications requiring air movement against resistance, such as HVAC systems and industrial processes. Their ability to maintain consistent airflow under varying pressure conditions distinguishes them from propeller fans, which rely on axial flow and are better suited for low-resistance environments.

Key Design Differences between Propeller and Centrifugal Fans

Propeller fans feature axial airflow with blades mounted on a hub, optimized for high flow rates at low pressure, making them ideal for ventilation and cooling applications. Centrifugal fans operate by drawing air into the center and expelling it radially, leveraging a scroll-shaped casing to generate higher pressure suitable for industrial processes and HVAC systems. The primary design distinction lies in the direction of airflow and pressure capabilities, where propeller fans offer efficient volume movement and centrifugal fans deliver greater pressure and controlled airflow.

Efficiency Comparison: Propeller vs Centrifugal Fans

Propeller fans typically offer higher efficiency in low-pressure, high-volume airflow applications due to their simple design and lower energy consumption. Centrifugal fans excel in situations requiring higher pressure and better control over airflow direction, often achieving improved efficiency in ducted systems with resistance. Efficiency differences depend on system requirements, with propeller fans favored for open spaces and centrifugal fans preferred for complex HVAC setups where pressure and noise reduction are critical factors.

Applications in Mechanical Engineering

Propeller fans are primarily used in applications requiring high airflow with low pressure, such as ventilation in HVAC systems, cooling of machinery, and exhaust in tunnels due to their efficient axial airflow. Centrifugal fans are favored in mechanical engineering tasks needing higher pressure and air movement through duct systems, including air pollution control, pneumatic conveying, and industrial process ventilation. Their robust design allows centrifugal fans to handle particulate-laden airflows and high-temperature gases, making them essential for harsh industrial environments.

Performance Metrics: Airflow, Pressure, and Noise

Propeller fans excel in high airflow applications with low-pressure demands, offering energy-efficient performance and relatively low noise levels due to their axial design. Centrifugal fans generate higher static pressure, making them suitable for ducted systems and environments requiring air movement against resistance, but they typically produce more noise due to increased turbulence. When selecting between the two, consider that propeller fans deliver optimal cubic feet per minute (CFM) at low noise decibels (dB), whereas centrifugal fans maintain better pressure measured in inches of water gauge (in. wg) and may require additional noise dampening for quieter operation.

Installation and Maintenance Considerations

Propeller fans generally require less complex installation due to their lightweight design and direct axial airflow, making them suitable for open or ducted spaces with minimal structural support. Centrifugal fans demand more precise installation, including secure mounting and alignment to accommodate higher pressure applications and ensure optimal performance. Maintenance for propeller fans is typically simpler, involving regular cleaning and blade inspection, while centrifugal fans require thorough checks of bearings, belts, and impeller balance to prevent operational inefficiencies.

Energy Consumption and Cost Analysis

Propeller fans typically consume less energy due to their lower pressure applications and simpler design, making them cost-effective for situations requiring high airflow with low resistance. Centrifugal fans, although more energy-intensive because of their capability to handle higher pressures and complex ductwork, offer greater efficiency in industrial environments demanding precise airflow control. Cost analysis must consider initial investment, maintenance, and operational energy expenses, where propeller fans generally have lower upfront and running costs, but centrifugal fans provide long-term savings in applications requiring robust performance.

Choosing the Right Fan for Specific Engineering Needs

Propeller fans provide high airflow at low pressure, making them ideal for ventilation and cooling where volume is prioritized over pressure, such as HVAC systems or exhaust applications. Centrifugal fans generate higher pressure and are suitable for ducted systems with resistance, including air handling units and industrial processes requiring precise airflow control. Selecting the right fan depends on factors like required pressure, airflow volume, system resistance, noise levels, and energy efficiency to optimize performance for specific engineering applications.

Axial flow

Axial flow propeller fans move air parallel to the shaft, offering high flow rates with low pressure, whereas centrifugal fans redirect airflow perpendicular to the shaft, generating higher pressure but lower flow.

Radial flow

Centrifugal fans generate radial flow by moving air perpendicularly outward from the impeller axis, providing higher pressure and efficient performance in applications requiring air movement against resistance compared to axial flow in propeller fans.

Static pressure

Centrifugal fans generate higher static pressure than propeller fans due to their design, making them ideal for applications requiring airflow through restrictive systems.

Volume flow rate

Propeller fans typically achieve higher volume flow rates with lower pressure compared to centrifugal fans, which excel at generating higher pressure at lower volume flow rates.

Impeller blade design

Propeller fans feature straight, aerodynamic blades designed for high airflow at low pressure, while centrifugal fans utilize curved or backward-inclined impeller blades optimized for higher pressure generation and efficient air movement through duct systems.

Fan efficiency

Centrifugal fans typically offer higher efficiency than propeller fans due to their ability to generate greater pressure and airflow in ducted systems.

Noise level (acoustic signature)

Propeller fans generally produce lower noise levels with a broadband acoustic signature, while centrifugal fans generate higher noise primarily characterized by tonal frequencies due to their impeller blade interactions.

Air velocity distribution

Propeller fans generate high air velocity with a uniform distribution along the axial direction, while centrifugal fans produce a higher pressure with air velocity distributed radially outward due to their impeller design.

Installation footprint

Propeller fans require a smaller installation footprint due to their axial design, while centrifugal fans need more space because of their larger housing and complex airflow path.

System resistance curve

The system resistance curve for a propeller fan is typically flatter, indicating lower pressure rise at increasing airflow, whereas the centrifugal fan exhibits a steeper system resistance curve with higher pressure capabilities, making it more suitable for high-resistance duct systems.

Propeller fan vs centrifugal fan Infographic

njnir.com

njnir.com